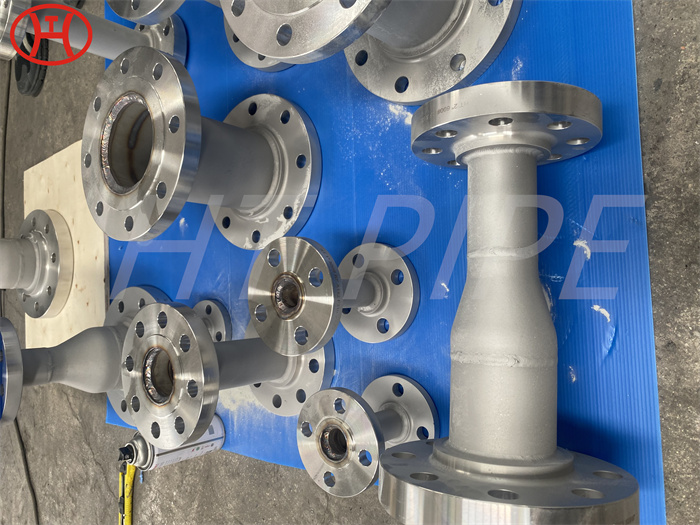

C276 Plate Forging Installation Scene

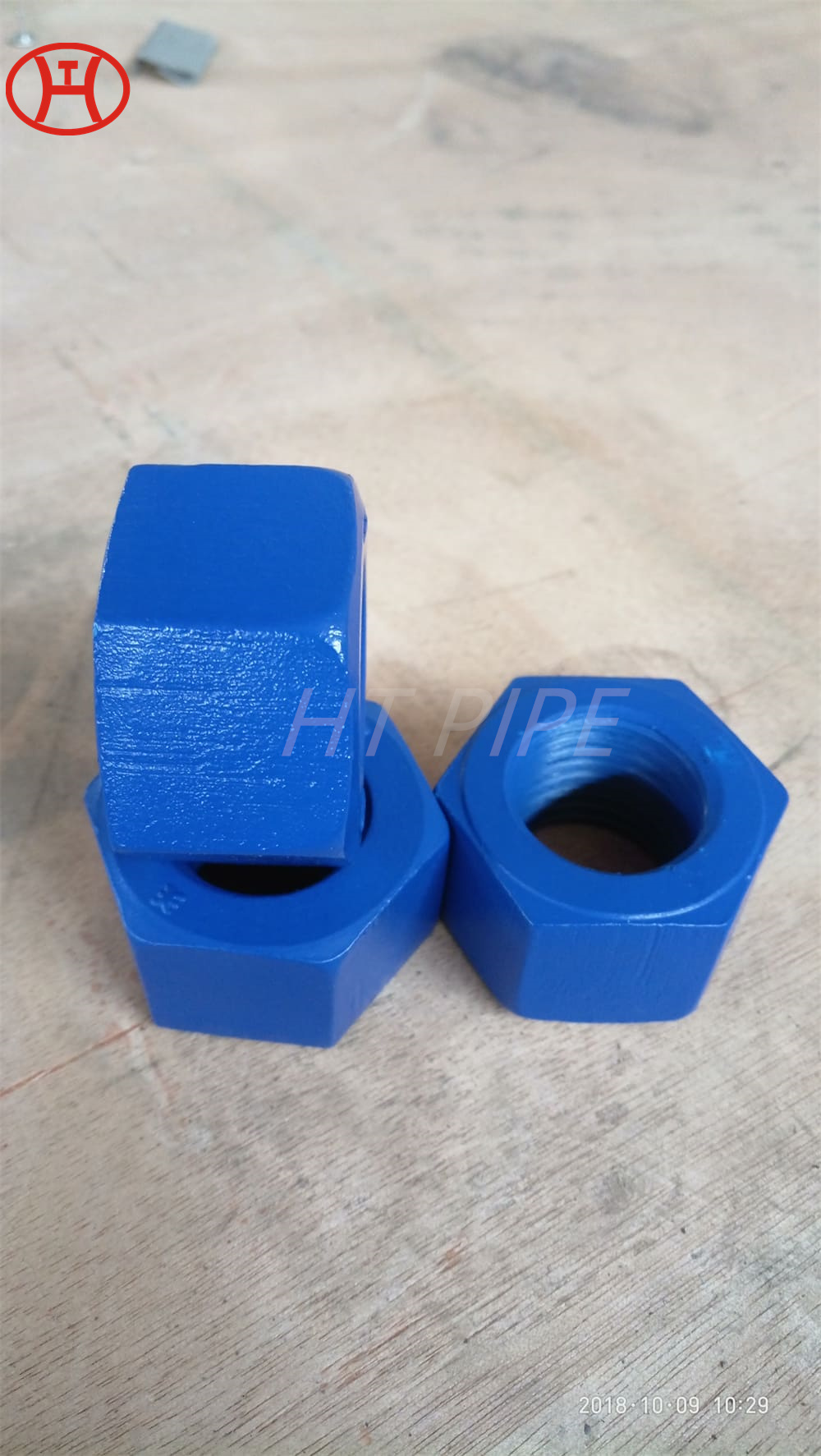

The applications range from chemical, petrochemical, power generation and OEM manufacturing industry as well other applications where vibration, high pressure or extremely corrosive conditions exist.

Nickel, cobalt and super alloy forgings are used for parts and components that must withstand harsh environments. Super alloys exhibit high heat resistance, corrosion resistance and acid resistance, coupled with wearability. They are ideal materials for parts and components used for pumps, valves, piping systems, process equipment, turbines and assemblies in the marine, chemical processing, oil and gas, aerospace and military industries. Nickel alloy forgings that are to be used in fresh or sea water applications are chosen based on the ability of a particular grade of nickel alloy to resist corrosion. Nickel also affects the thermal expansion properties of a metal, either by expansion predictability or low thermal expansion control.