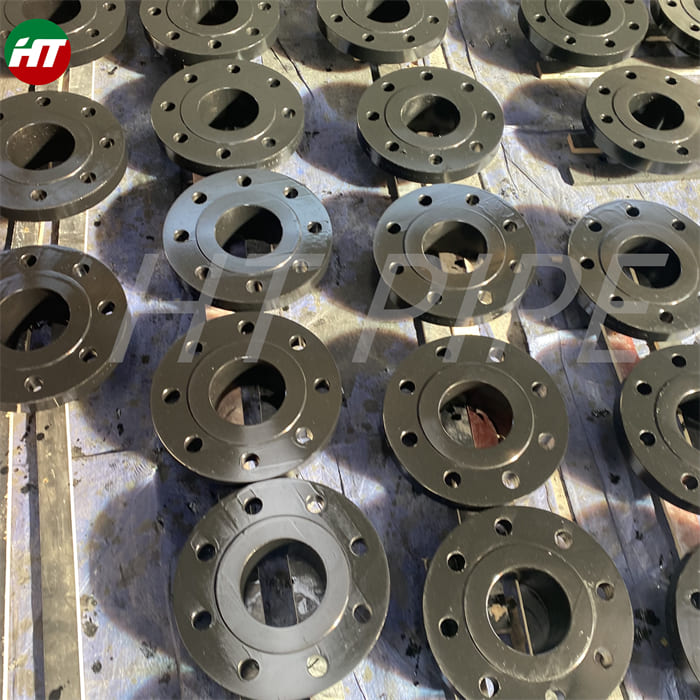

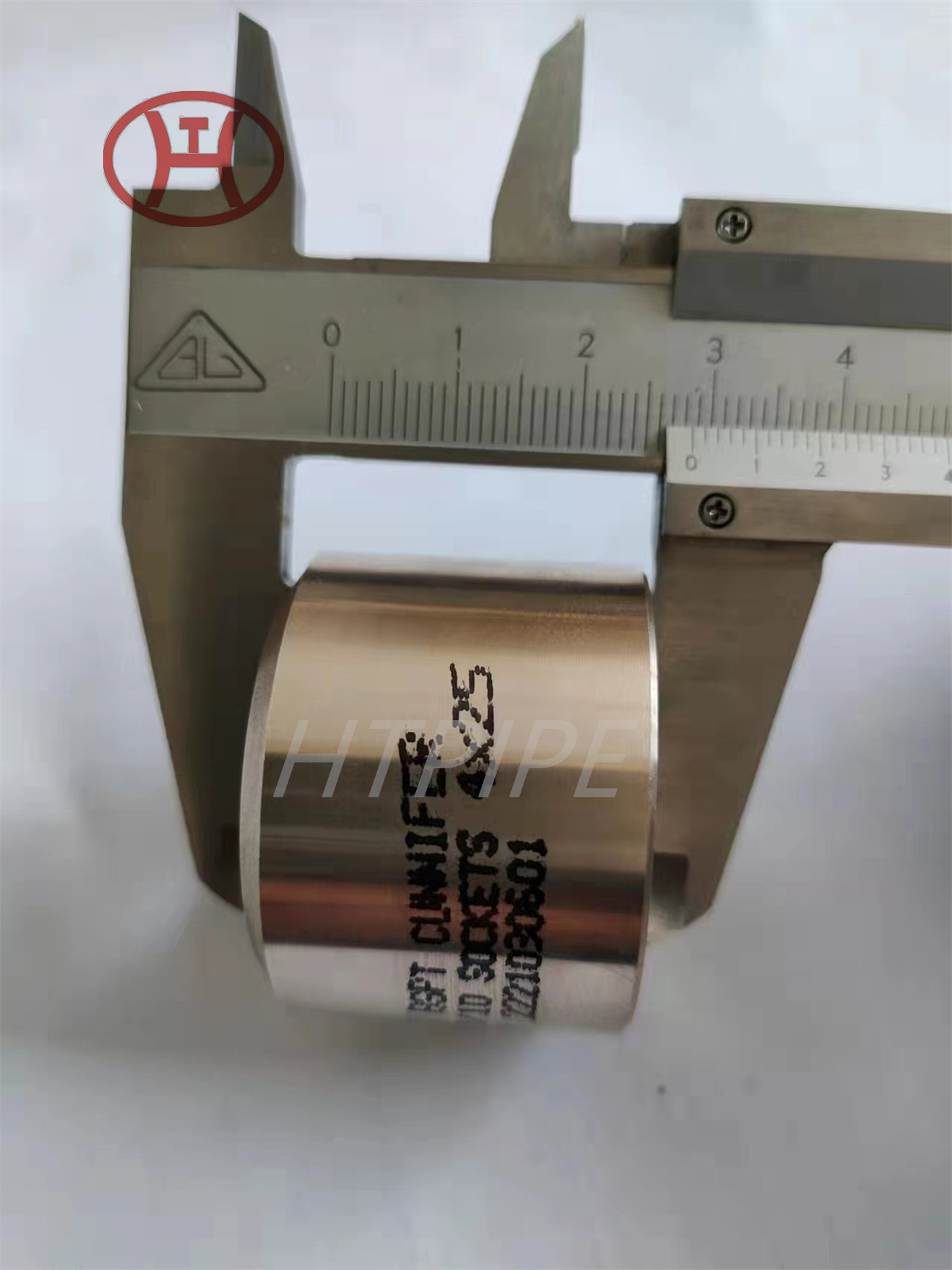

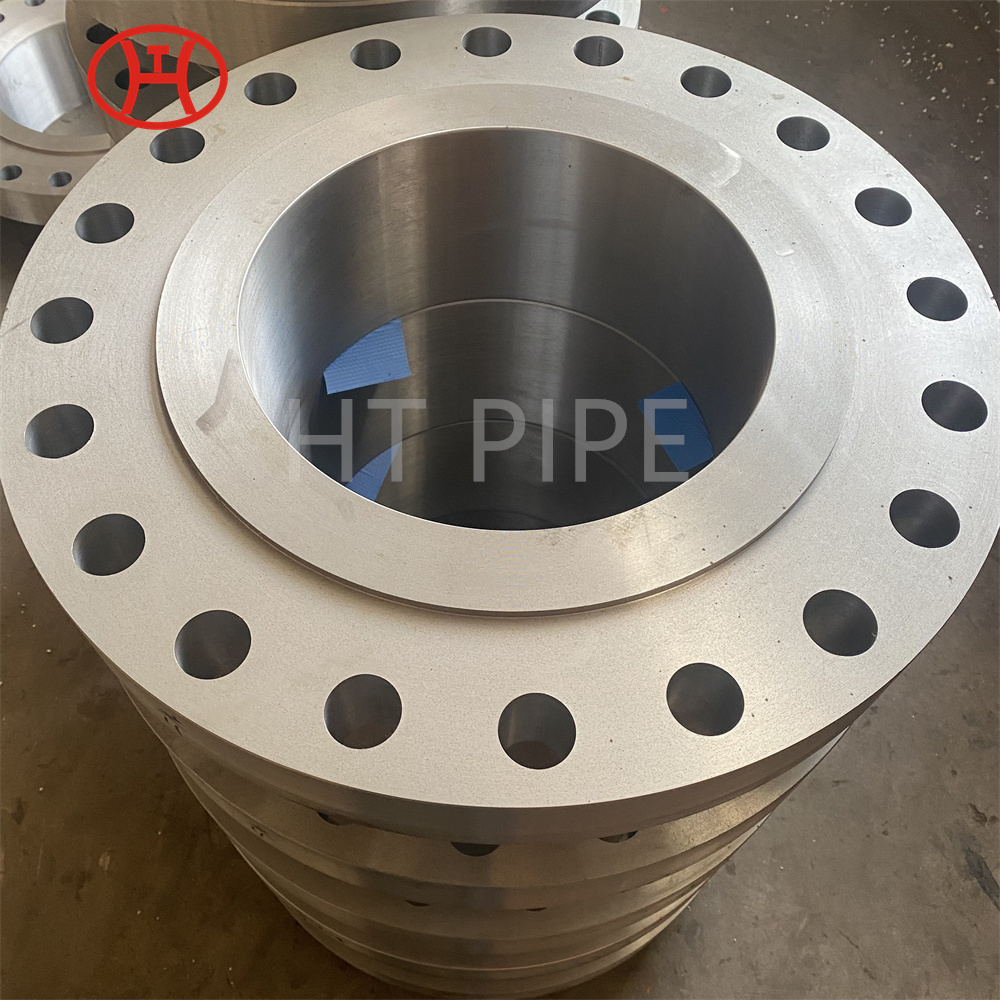

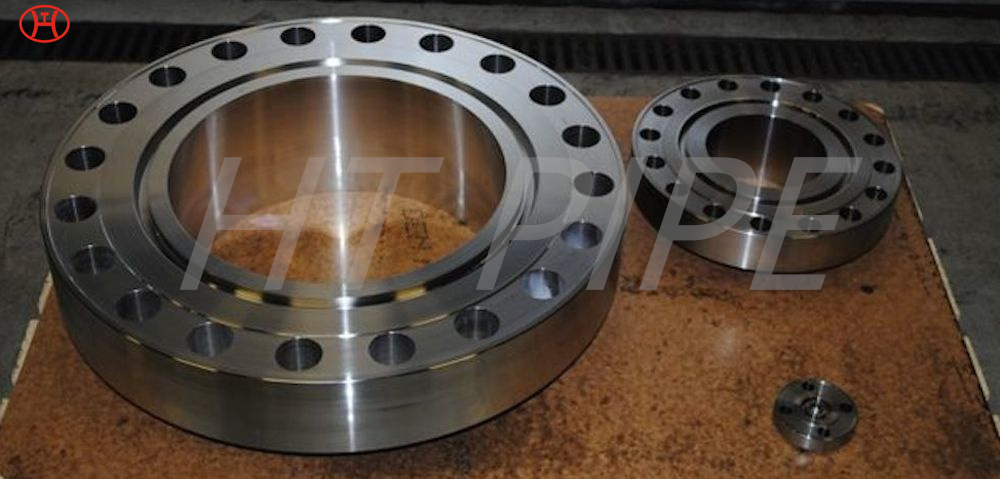

Carbon Steel ASTM A105 A105N Industrial Flanges

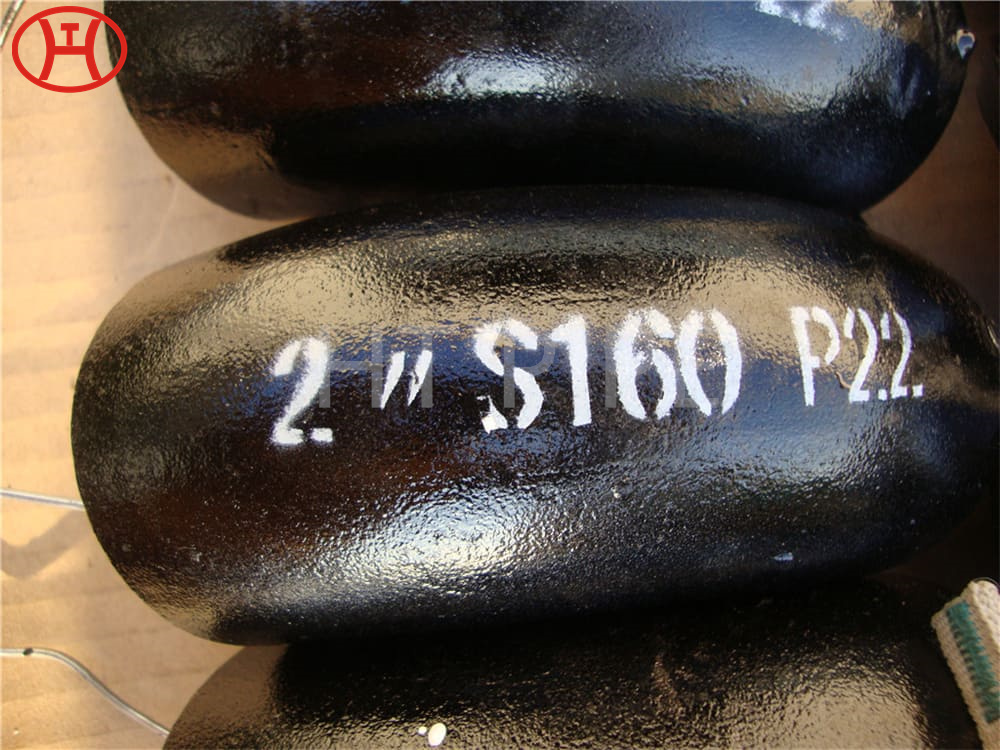

Designed specifically for low-temperature usage, this carbon steel grade shares close similarities with ASTM A105N (SA105N) grade. This grade requires notch durability testing, and applicable for many industries.

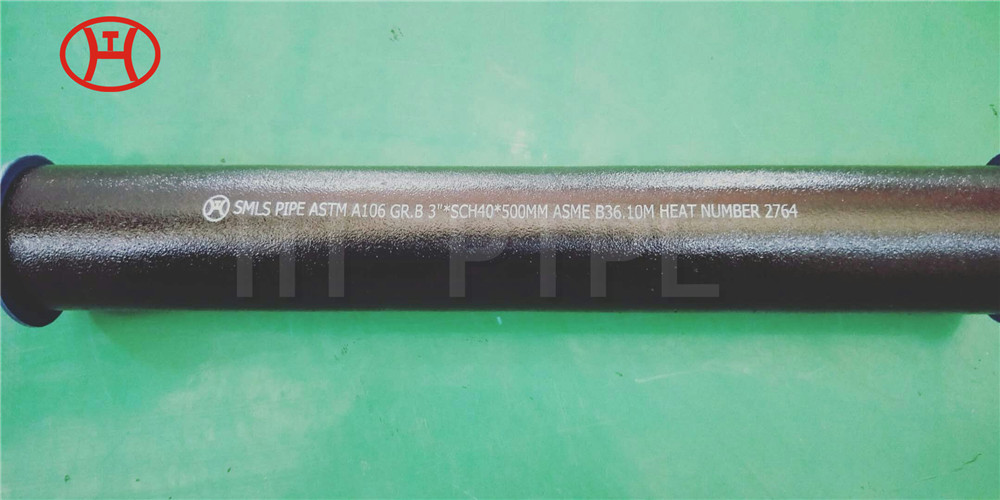

Modern carbon is a common steel with carbon content up to 2.1% by weight and primarily alloyed with iron. The term ¡°carbon steel¡± may also be used to call out steel which does not have a large amount of chromium or nickel. The carbon content can vary for A105 with a maximum allowable of 0.35 as a percentage composition. As the carbon content increases, the steel hardens and increases in strength through heat treatment processes. Many common treatment techniques in the industry are quenching, tempering, and normalizing. As carbon steel is treated, it become less ductile and brittle. This makes it slightly more difficult to shape and weld, however the trade off in field service is often considered worth the extra effort to form the necessary weld seals.

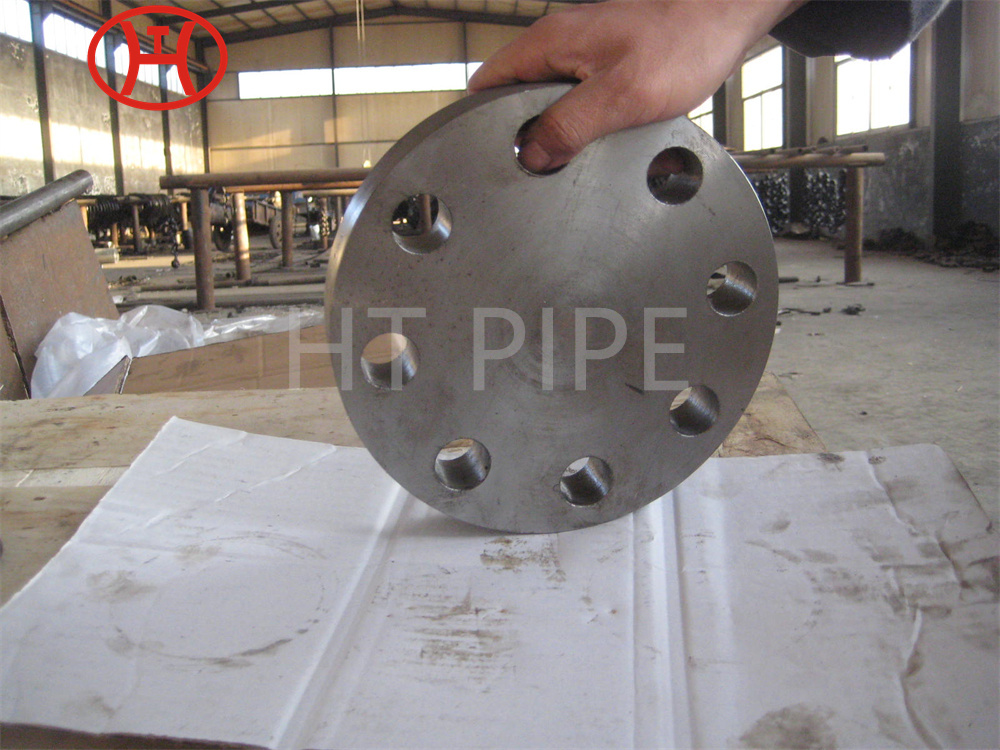

Differences between forged steel flange and cast iron flange

Forging process is more expensive than the cast iron process

Casting iron can be manufactured to fit different complex profiles

Forging process doesn’t lead to the manufacture of big or uneven brain

Cast iron flange is used exclusively for non-pressure pipelines, while forged Steel Flange is used in higher pressure pipeline

The centrifugal machine is used to manufacture high precision cast iron flange than standard cast flanges

Forged Steel can easily be cut, and it can withstand higher tensile strength

Overall, forged steel is better than cast iron flanges in terms of performance as it comes with a better shape and also much lower carbon content which leads to less rusting.