Carbon steel reducer ASTM A234 WPB concentric reducer 6in by 2in

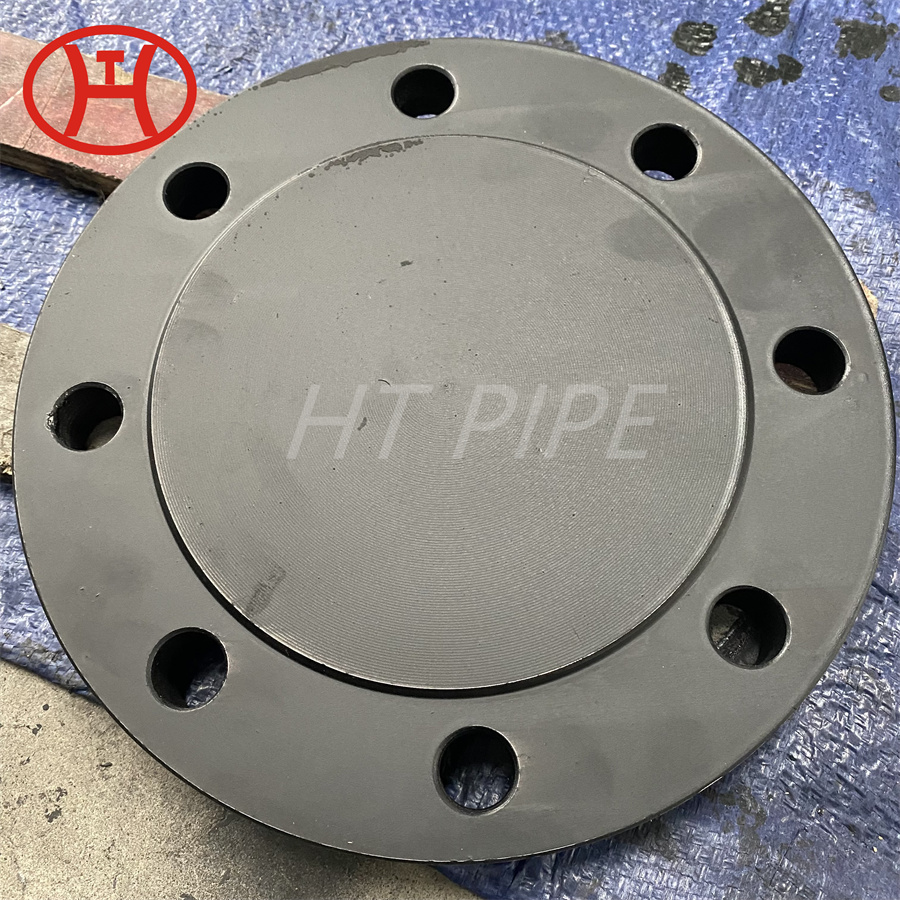

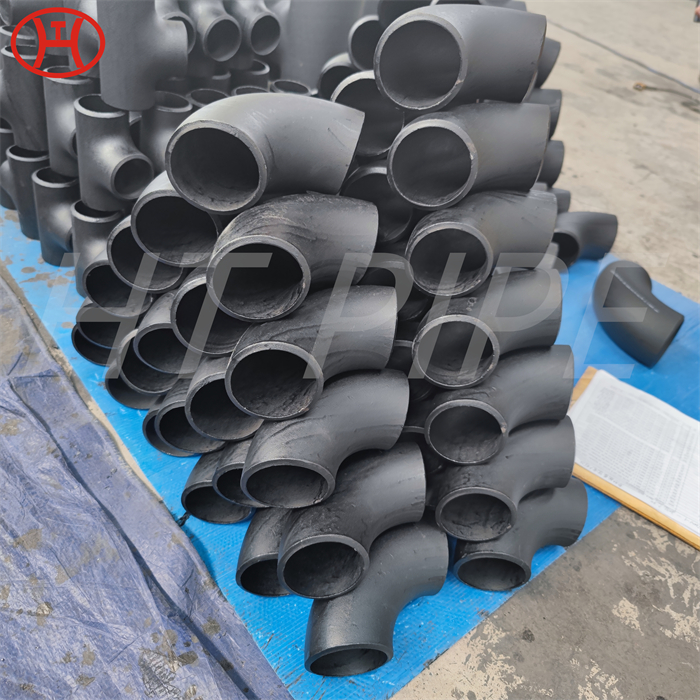

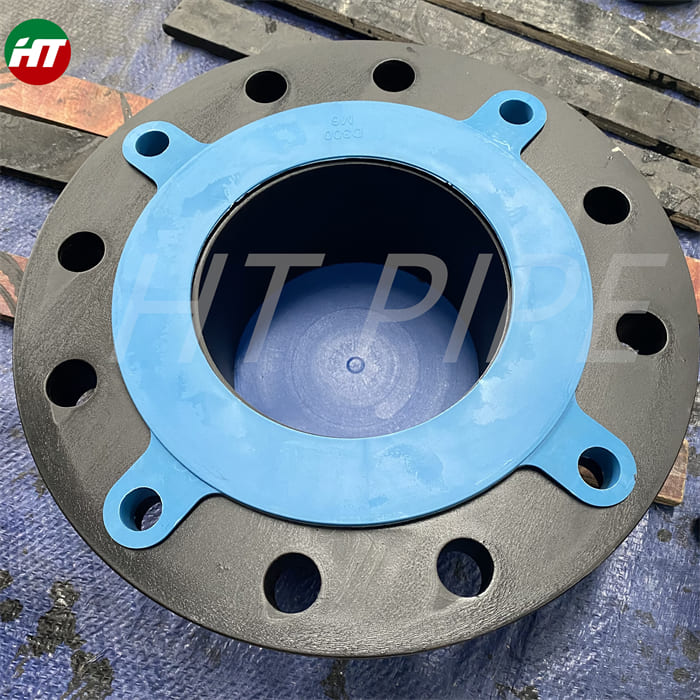

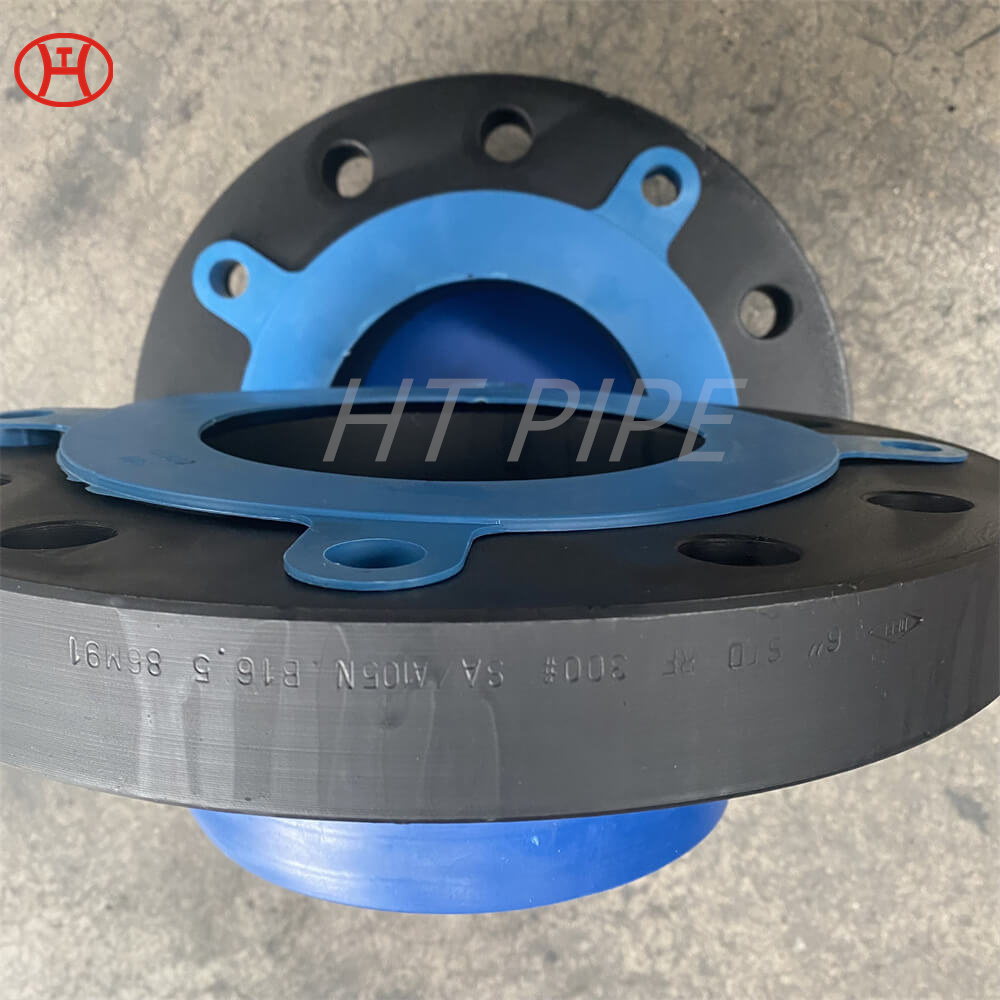

A butt weld pipe fitting is designed to be welded on site at its end(s) to connect pipe(s) together and allow change in direction or pipe diameter, or branching or ending.

This fitting then becomes part of a system for transporting fluids (oil, gas, steam, chemicals, …) in a safe and efficient manner, over short or long distances.

⇒A reducer allows⇐ for a change in pipe size to meet flow requirements or to adapt to existing piping. The length of the reduction is usually equal to the average of the larger and smaller pipe diameters. Reducers are typically concentric, but eccentric reducers can be used to maintain the same top of pipe or bottom of pipe level.

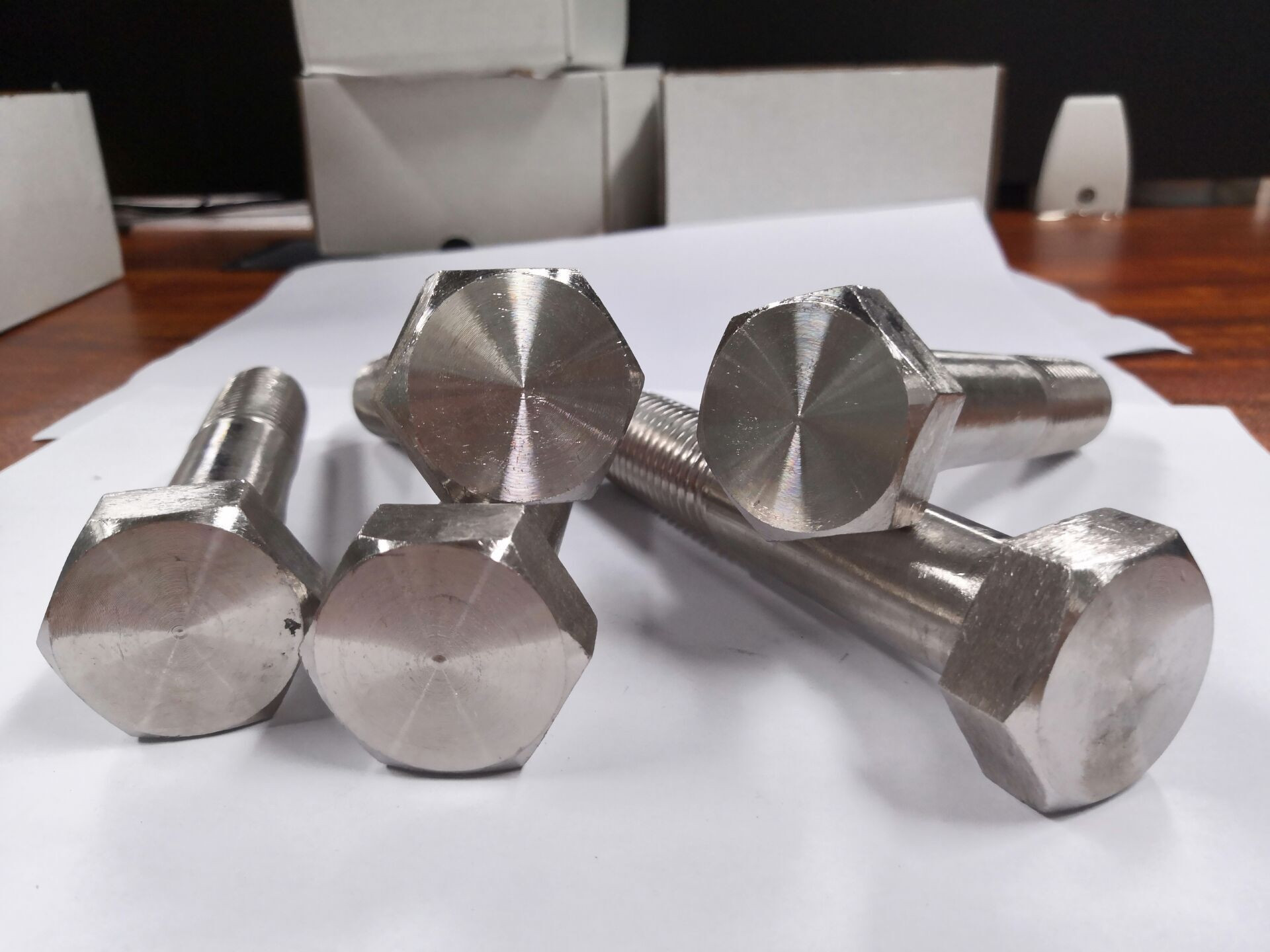

Steel pipe fitting are made of carbon or alloy steel pipe, plates, profiles, to a certain shape that could make a function (Change the fluids direction or rate) in pipeline systems. Mostly these fittings includes steel elbow (45 or 90 degree bend), tee, reducer (concentric or eccentric reducer), cross, caps, nipple, flanges, gasket, studs and etc.

For industrial purposes, in pipeline systems usually we need to change the transmission direction; Adjust fluids (oil and gas, water, slurry) flow rate; Open or close the pipelines, etc. So to complete these activities, steel pipe fittings will be applied.