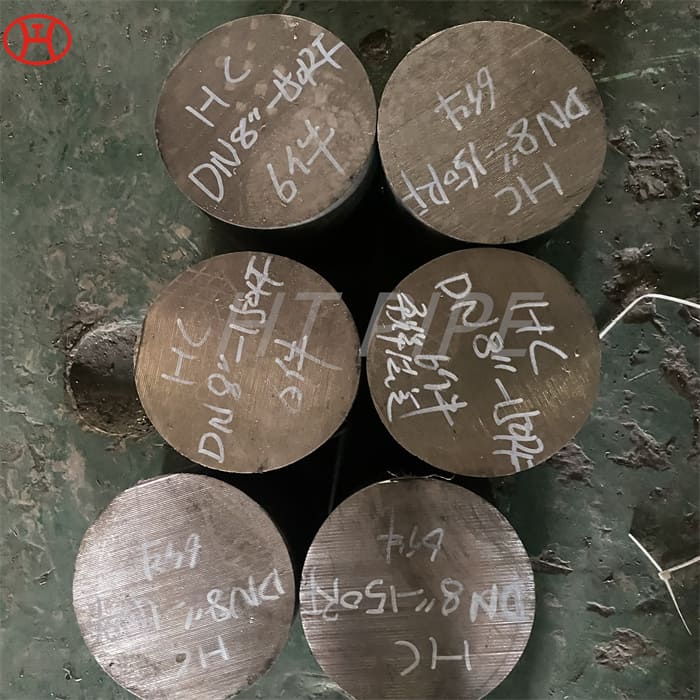

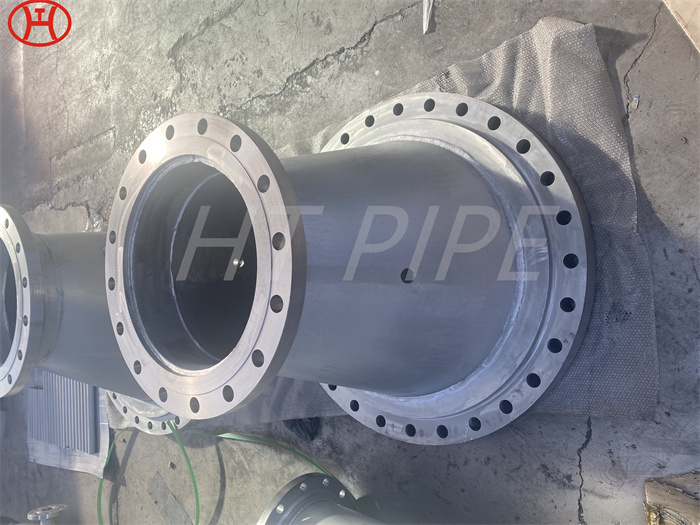

The Chinese Supplier of ASTM A815 UNS S32750 super duplex stainless steel pipe fitting equal tee

The UNS S32750 standard of Pipe Fittings consists of 25% chromium, 4% molybdenum, and 7% nickel. The UNS S32750 Pipe Fittings have a 50-50 microstructure of ferritic and austenitic steel grades with improved strength.

ANSI B16.9, ANSI B16.28, MSS SP-43, or MSS SP-79 Super Duplex 2507 Butt weld Pipe Fitting, Werkstoff No 1.4410 Super Duplex Buttweld Pipe Fittings, Super Duplex Steel ASTM A815 Fittings, Manufacturer Of ASTM A815 Super Duplex Steel UNS S32750 Buttweld Fittings in China.

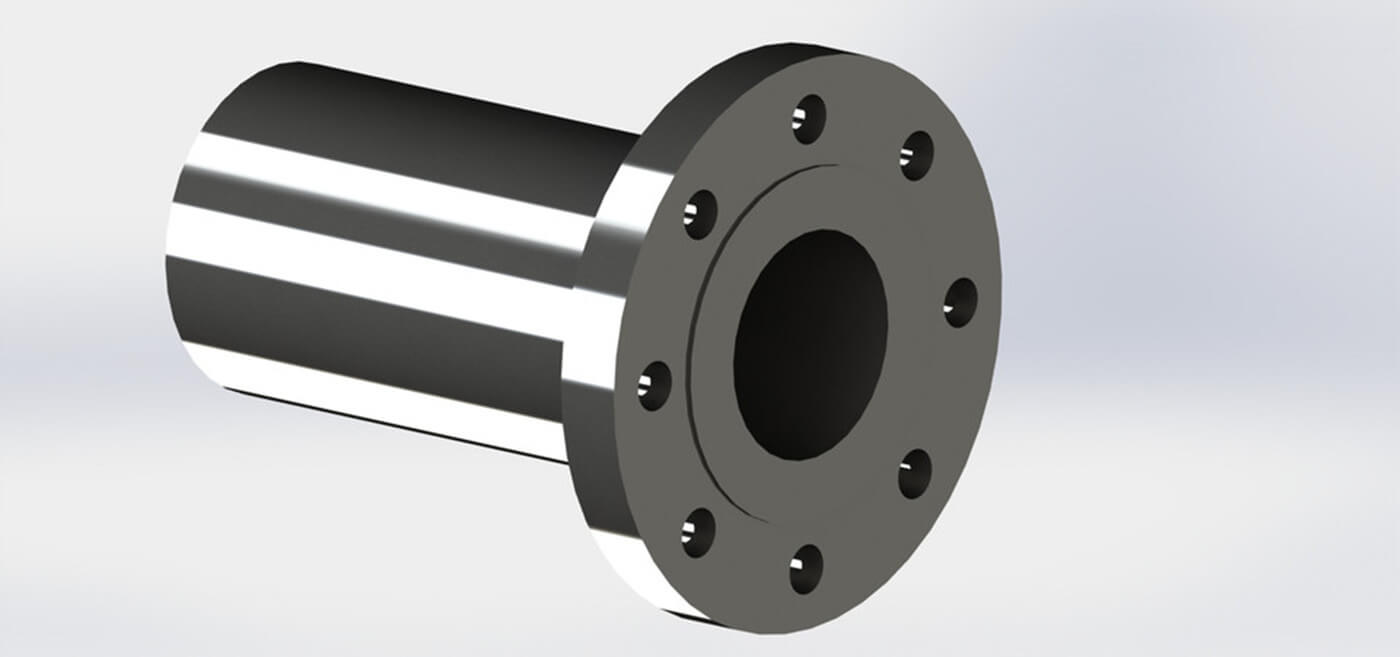

A fitting is used to change the direction of the pipe. The simplest way to do it is to bend the pipe. However, it will stretch and thin out the outer walls of the pipe. It will also thicken the inner wall of the pipe. Super Duplex Stainless Steel Pipe Fittings are used which are an enhanced grade of Duplex fittings Super Duplex 2507 Pipe Fittings hence have a higher PREN pitting number. A higher pitting number indicates superior pitting resistance.

Uns S32750 Duplex Steel Tee is used in the textile and marine industry. ASME B16.9 Super Duplex Seamless Fittings display a tensile strength of 1,16,000 psi and yield strength of 80,000 psi. The Asme Sa815 Super Duplex Butt Weld Pipe Fittings are priced between Rs.850 to Rs. 5400. Astm A815 Uns S32750 Long Radius Elbow can be cold formed using regular cold forming methods or can be hot formed between 1875 degrees C and 2250 degrees C.

Also We offer wide range of Super Duplex Steel ASTM A815 Pipe Fittings such as Super Duplex Steel S32750 tee, S32760 Super Duplex End Pipe Cap, Super Duplex Steel 2507 reducer, Super Duplex Steel cross, Super Duplex Steel S32750 elbow, Super Duplex Steel S32760 stub ends etc.

Standard Product TyPes Size

ASME B16.9 Long Radius Elbows,Long Radius Reducing Elbows,Long Radius Returns,Short Radius Elbows,Short Radius 180-deg Rerurns,3D elbows,Straight Tees,Straight Crosses,Reducing Outlet Tees,Reducing Outlet Crosses,Lap Joint Stub Ends,Caps,Reducers Size:1/2″-48″ Wall thickness:SCH5S-SCHXXS

ASME B16.28 Short Radius Elbows,Short Radius 180-deg Returns Size:1/2″-24″ Wall thickness:SCH5S-SCHXXS

ASME B16.49 30¡ã 45¡ã 60¡ã 90¡ã Long Radius Short Radius Bend Size:1/8″-12″ Wall thickness:SCH5S-SCHXXS

MSS-SP43 Long Radius Elbows,Straight and Reducing-on-the-Outlet Tees,Lap Joint Stub ends,caps,long radius 180 Degree returns,concentric reducers,eccentric reducers Size:1/2″-24″ Wall thickness:SCH5S-SCHXXS

MSS-SP75 Long Radius Elbows,3R elbows,straight tees,reducing outlet tees,caps,reducers Size:16″-60″ Wall thickness:SCH6S-SCHXXS

ISO, DIN, JIS All Kind of Buttwelding Product or as Client’s Drawing As the Client’s Demand

Super Duplex Steel UNS S32750 Buttweld Fittings Chemical Composition:

Grade |

C | Si | Mn | Ni | P | S | Cr | Mo | N |

S32750 |

max 0.03 | max 0.8 | max 1.2 | 6 – 8 | max 0.035 | max 0.020 | 24 – 26 | 3 – 5 | 0.24 – 0.32 |

Mechanical Properties of Super Duplex Steel DIN 1.4410 Pipe Fittings:

| UNS S32750 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |