Cu Ni alloy pipe fittings ASTM SB 466 UNS C70600 elbow

Copper-nickel or copper-nickel elbows are moderately strong and commonly found in marine saltwater applications.

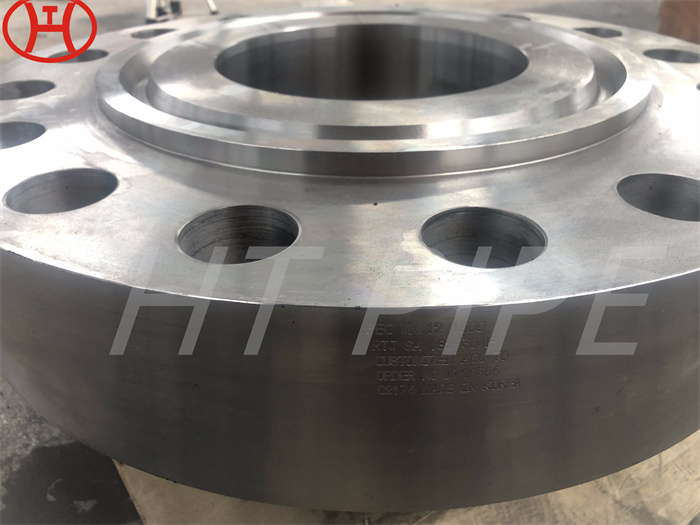

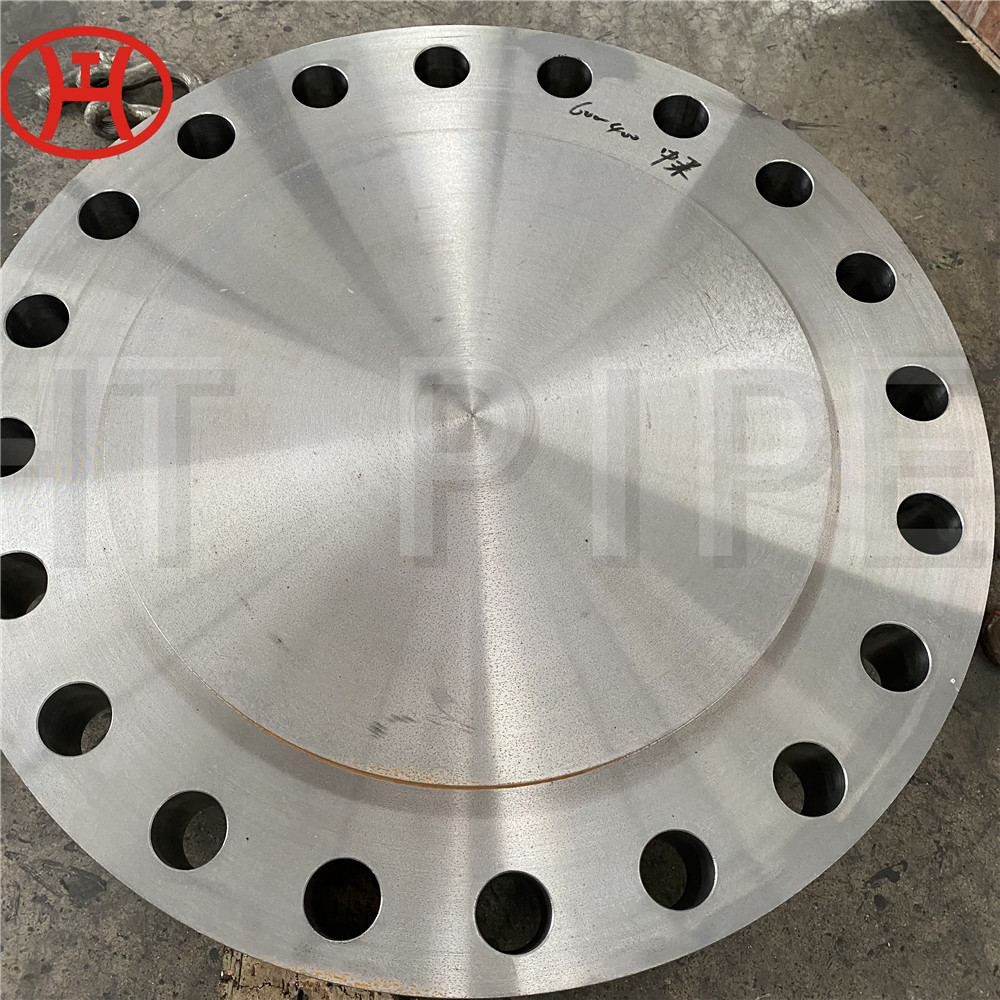

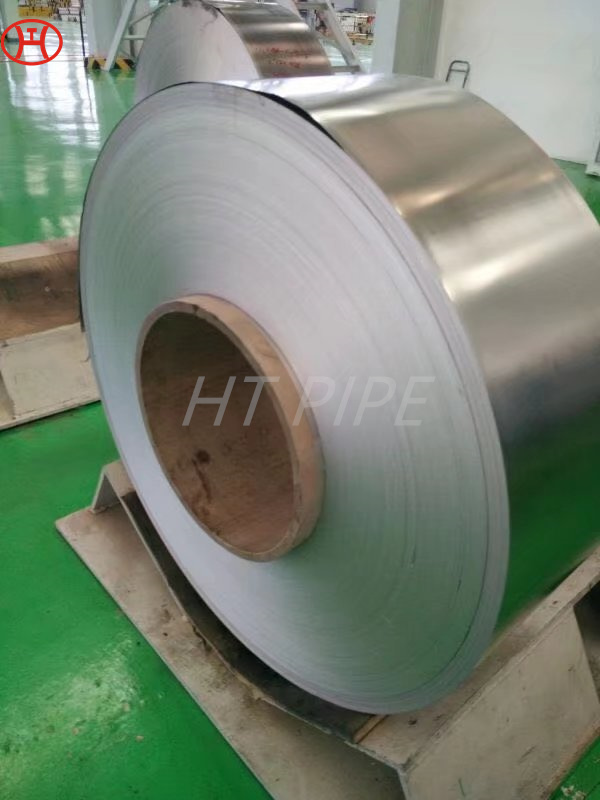

UNS C70600 elbows are a common fitting in the industry for changing the direction of flow in piping systems. These UNS C70600 elbows are designed at different angles to meet specific requirements. Copper-nickel alloys are exclusive blends of copper and nickel. In addition, the addition of manganese, chromium, niobium and iron improves their corrosion resistance and strength. Nickel is soluble in copper, which purifies the copper-nickel alloy to a single-phase alpha structure. The addition of these elements makes our copper-nickel elbows more resistant to corrosion and corrosion with a slight increase in strength, allowing them to be used in different industrial applications.

UNS C70600 elbow can be used in seawater/marine systems, heat exchangers and condensers, offshore fire systems, naval vessels, desalination and other piping systems. UNS C70600 Copper-nickel alloy elbows have excellent resistance to biofouling and marine corrosion, and possess good fabricability. Copper gains more strength and corrosion resistance when nickel is added to it.

UNS C70600 elbow has excellent corrosion resistance even in marine environments. This alloy possesses average high strength and good creep resistance at high temperatures, and costs more in comparison to copper-aluminum alloys and other alloys with similar mechanical properties.

Chemical Composition

The following table shows the chemical composition of UNS C70600 copper nickel alloy.

| Element | Content (%) |

|---|---|

| Cu | 88.7 |

| Fe | 13 |

| Ni | 10 |

Physical Properties

The physical properties of UNS C70600 copper nickel alloy are outlined in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.94 g/cm3 | 0.323 lb/in³ |

Mechanical Properties

The mechanical properties of UNS C70600 copper nickel alloy are tabulated below.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 303-414 MPa | 43900-60000 psi |

| Yield strength (depending on temper) | 110-393 MPa | 16000-57000 psi |

| Elongation at break (in 254 mm) | 42% | 42% |

| Elastic modulus | 117 GPa | 17000 ksi |

| Poisson’s ratio | 0.34 | 0.34 |

| Machinability (UNS C36000 (free-cutting brass) = 100) | 20 | 20 |

| Shear modulus | 52.0 GPa | 7540 ksi |