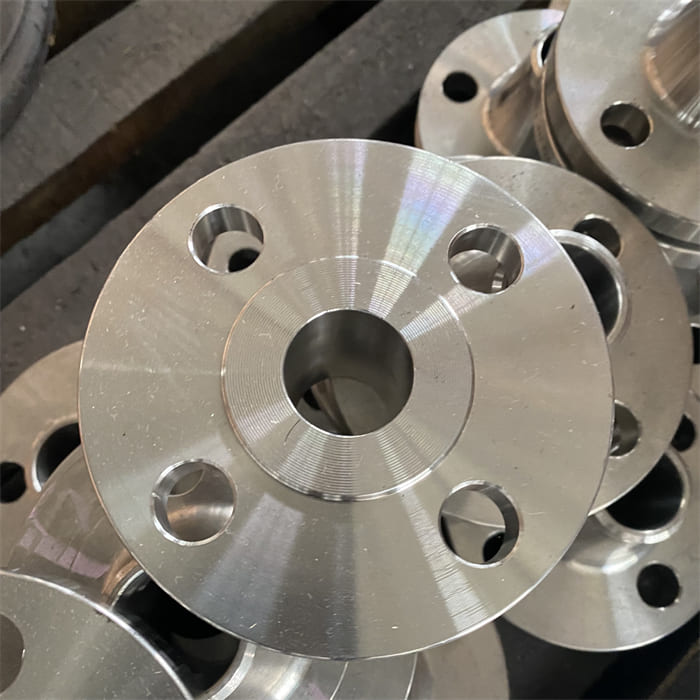

Din Jis Standard Ansi 150 Ff Adapter Asme B16.5 Lb 900 Weld Neck# 316L Forged Flange

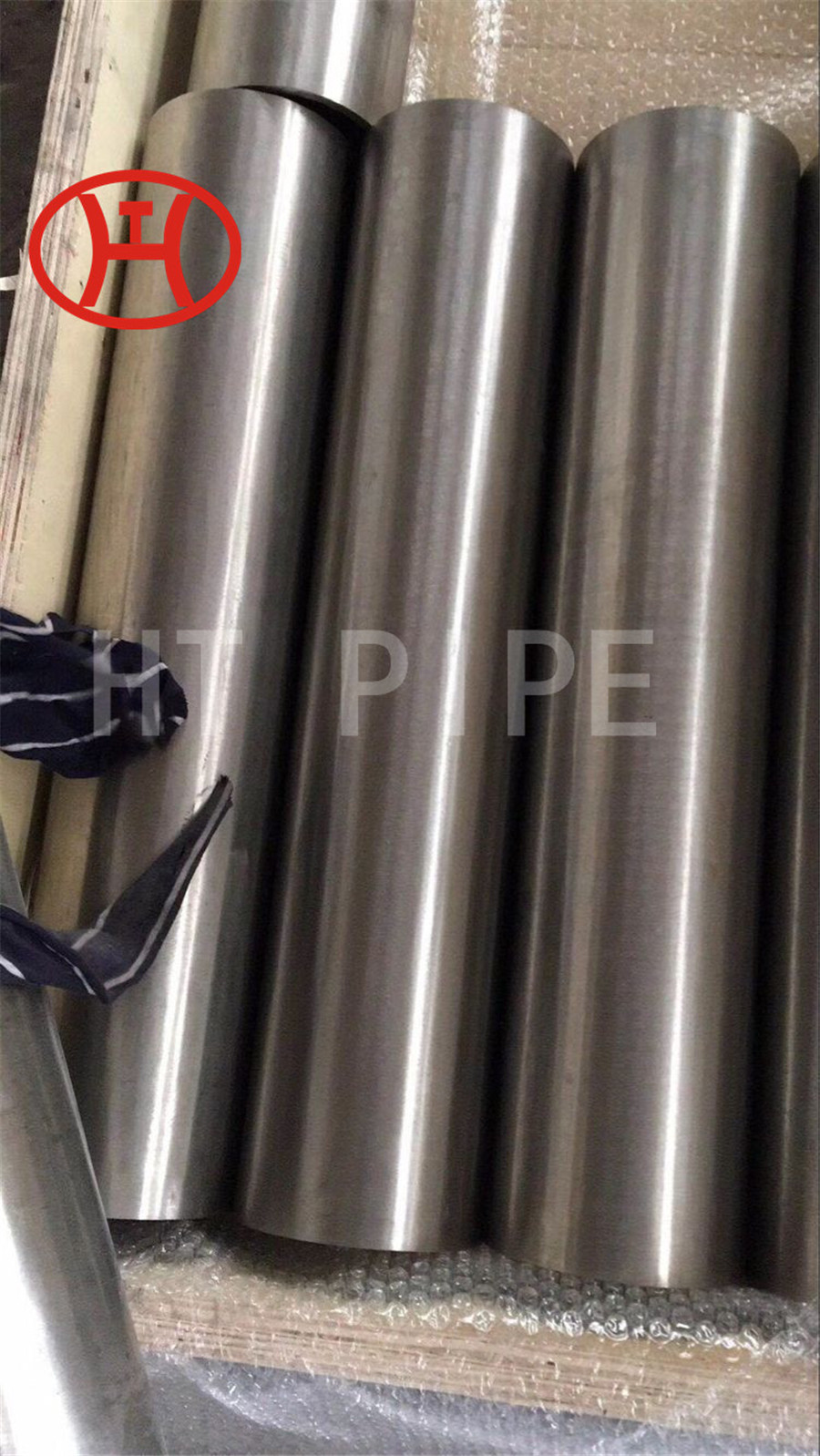

ASTM A182 F316 is a forging material specification for 316 grade stainless steel and is used for manufacturing bare forgings or forged and machined products for applications involving high temperature service.

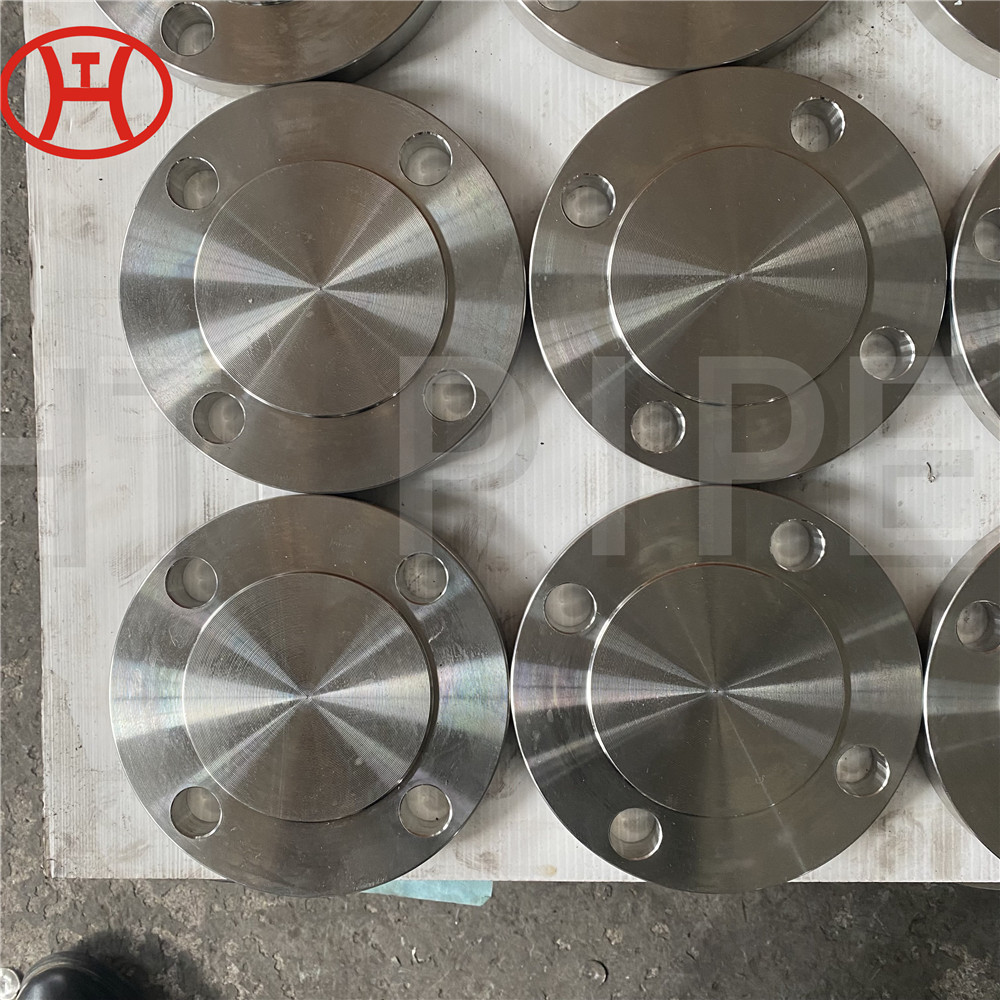

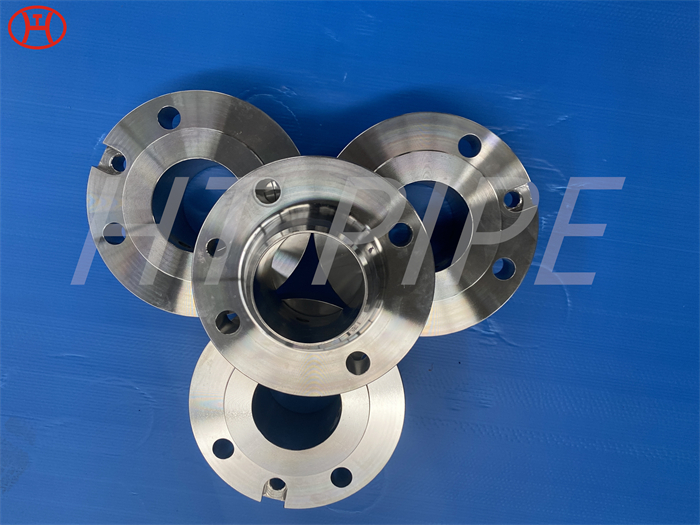

Stainless Steel 316Ti Flanges, SS 316L Flange, 316 Steel Plate Flanges Suppliers, Stainless Steel 316H Pipe Flange, ASTM A182/A240 Stainless Steel 316L Slip On Flanges Dealer, SS Grades 316/316Ti/316H/316L Industrial Flanges Stockists, Distributors of ASME SA182 Stainless Steel 316L Blind Flanges in China.

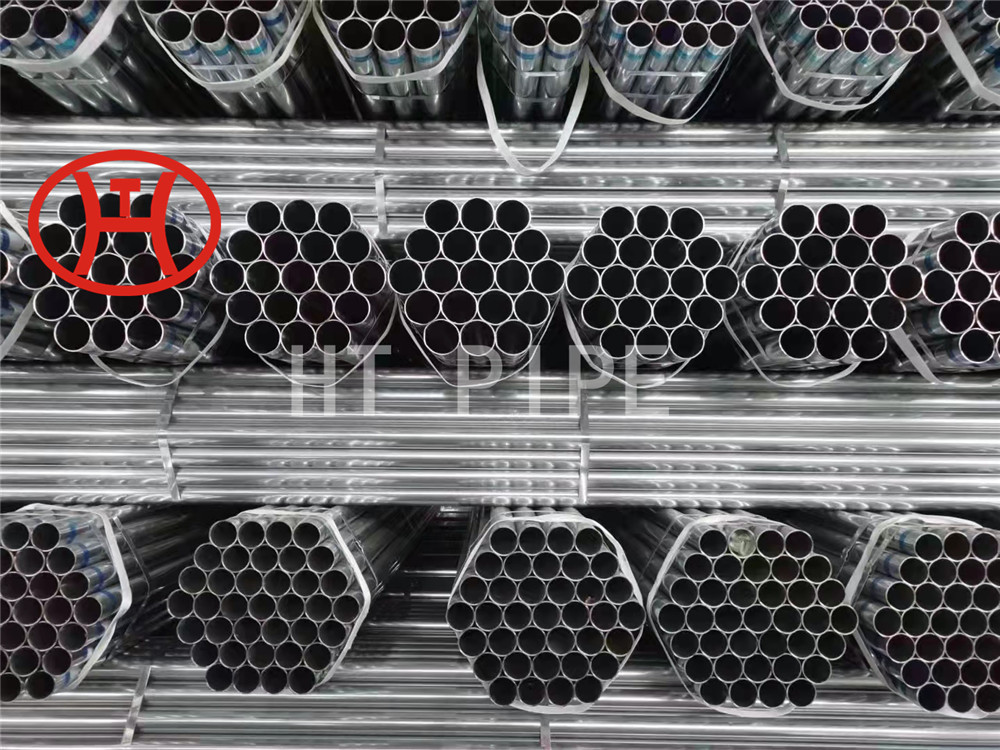

F316/316L is the most commonly used austenitic stainless steel in the chemical process industry. The addition of molybdenum increases general corrosion resistance, improves chloride pitting resistance and strengthens the alloy in high temperature service. Through the controlled addition of nitrogen it is common for 316/316L to meet the mechanical properties of 316 straight grade, while maintaining a low carbon content.

316L Flange is an improved version of 304 due to the addition of molybdenum and a slightly higher nickel content. The resultant composition of 316 gives the steel improved corrosion resistance in many aggressive environments. The molybdenum makes the steel more resistant to pitting and crevice corrosion in chloride-contaminated media, seawater and to acetic acid vapours. The lower rate of general corrosion in mildly corrosive environments gives the steel good atmospheric corrosion resistance in polluted marine atmospheres.

316 offers higher strength and better creep resistance at higher temperatures than 304. 316 also provides excellent mechanical and corrosion properties at sub-zero temperatures. When there is a danger of corrosion in the heat-affected zones of weldments, the lower-carbon variety 316L should be used.

Stainless steel plate flanges PN16 type 01 B1 according EN1092-1 are widely used in pipelines for transport of fluids like fuel, oil, steam, water and more. Тhe advantage of stainless steel flanges is that they withstand aggressive environments and do not need painting. Plate flanges are mostly used in less demanding connections. Flanges type 01 can be easily welded in place and provide rigid and robust assembly. Slip-on flanges provide easy access for further mounting in place of valves and equipment.

ASTM A182 Stainless Steel 316L Flanges Specifications

| Specifications : | ASTM A182 / ASTM A240 & ASME SA182 / ASME SA240 |

| Dimensions : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size : | 1/2″ (15 NB) to 48″ (1200NB) |

| Standard : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Class / Pressure : | 150#, 300#, 600#, 900#, 1500#, 2500# | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Stainless Steel 316L Flanges Size

| Products | Size | |

| ASTM A182 SS 316L Slip-On Flanges | ASTM A182 SS 316L Weld Neck Flanges | Sizes 1/8″ – 36″ Raised Face or Flat Face |

| ASTM A182 SS 316L Blind Flanges | ASTM A182 SS 316L Lap Joint Flanges | |

| ASTM A182 SS 316L Threaded Flanges | ASTM A182 SS 316L Socket Weld Flanges | |

| ASTM A182 SS 316L Plate Flanges | ASTM A182 SS 316L Ring Joint Type Face (RTJ) Flanges | |

| ASTM A182 SS 316L Spectacle Blind Flanges | ASTM A182 SS 316L High Hub Blind Flanges | |

| ASTM A182 SS 316L Orifice Flanges | ASTM A182 SS 316L Reducing Flanges | |

| ASTM A182 SS 316L Square Flanges | ASTM A182 SS 316L Groove & Tongue Flanges | |

| ASTM A182 SS 316L Long Neck Weld Flanges | ASTM A182 SS 316L Spades and Ring Spacers Flanges | |

| ASTM A182 SS 316L Weldo / Nipo Flanges | ASTM A182 SS 316L Expander Flanges | |