Duplex stainless steel pipe price per ton

On average, duplex stainless steel is about twice as strong as either ferritic or austenitic stainless steels. High toughness and ductility. Duplex stainless steel can be more easily formed under pressure than ferritic grades and also have superior toughness.

Duplex steel pipes have a mixed microstructure with roughly equal proportions of ferrite and austenite. UNS S32205 pipes are a family of grades whose corrosion properties depend on their alloy content.

These UNS S32205 pipe provide a balance of properties resulting from their duplex metal structures. The mixed ferritic-martensitic structure of the 409LNi provides better strength and hardness compared to the straight ferritic materials and better sinterability and ductility compared to the martensitic alloys.

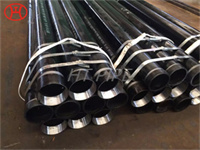

In addition, UNS S32205 pipes are mainly used in piping systems that transport fluids or gases. We manufacture steel pipes from alloy steels that contain nickel and chromium, which give ASTM A790 UNS S32205 Duplex Stainless Steel Pipe the corrosion-resistant properties. Stainless steel tubing resists oxidation, making it a low-maintenance solution for high temperature and chemical applications. Due to its ease of cleaning and sterilization, 2205 tubing is also suitable for applications involving food, beverage and pharmaceutical applications.

ASTM A790 Seamless Pipes have improved strength over austenitic stainless steels and also improved resistance to localised corrosion, particularly pitting, crevice corrosion and stress corrosion cracking. They are characterised by high chromium (19–28%) and molybdenum (up to 5%) and lower nickel contents than austenitic stainless steels. The chemical composition based on high contents of Cr and Mo, improves intergranular and pitting corrosion resistance, respectively. Additions of nitrogen can promote structural hardening by interstitial solid solution mechanism, which raises the yield strength and ultimate strength values without impairing toughness.

When welding duplex alloys, the heat input and interpass temperature must be controlled to maintain the ferrite-austenite balance. Otherwise, the advantages of using the duplex material will be lost. The time spent at 1,300 °F to 1,800 °F must be controlled. The heat-affected zone (HAZ) time-at-temperature is critical in controlling the intermetallic phases.

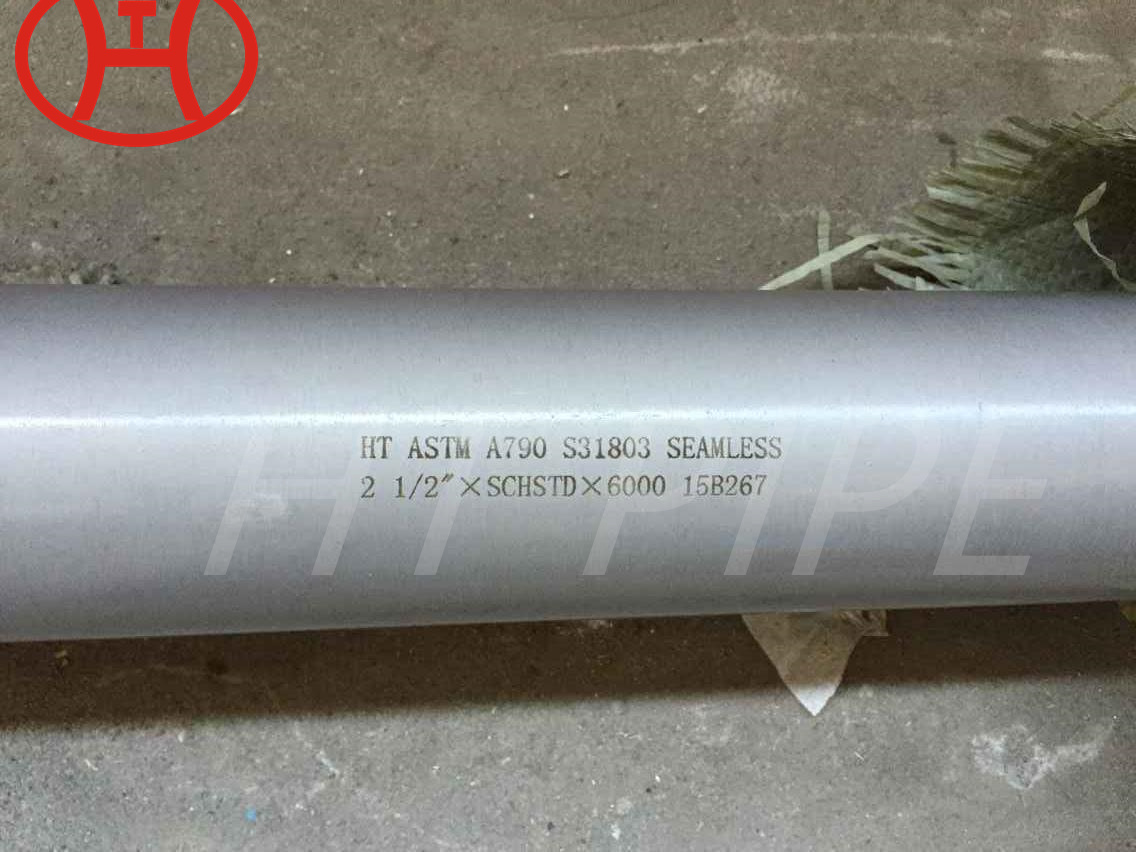

ASTM A790 UNS 32205 Duplex Stainless Steel Seamless Pipes

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Specification | ASTM A789, ASTM A790, ASTM A928, ASME SA789, ASME SA790, ASME SA928 |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Grades | UNS S32205, UNS S31803, UNS S32750, UNS S32760, SAF® 2205, SAF® 2507, FERRINOX® 225, AMINOX® 225, ZERON® 100 |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Type | Seamless / Welded / ERW / EFW / Cold Draw / Hot Finish / Cold Finish |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Outer Diameter Size | Seamless – 1/2″ NB TO 18″ NB Welded / ERW- 1″ NB TO 16″ NB EFW – 8″ NB TO 110″ NB |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Wall Thickness | Schedule 10 to Schedule 160 (3 mm to 100 mm Thickness) |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Ends | Plain Ends / Beveled Ends |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw, Bright Annealed |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Other Testing | Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiograph HIC Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM And ASME |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

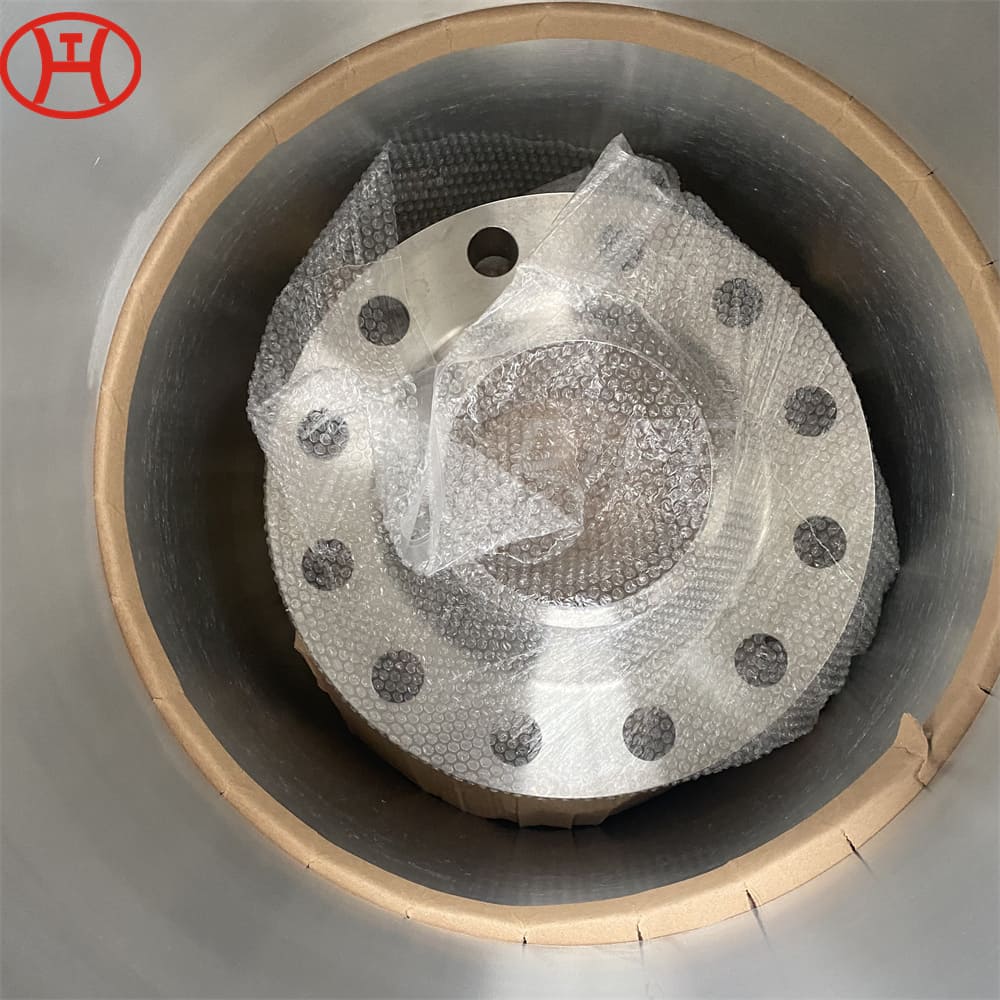

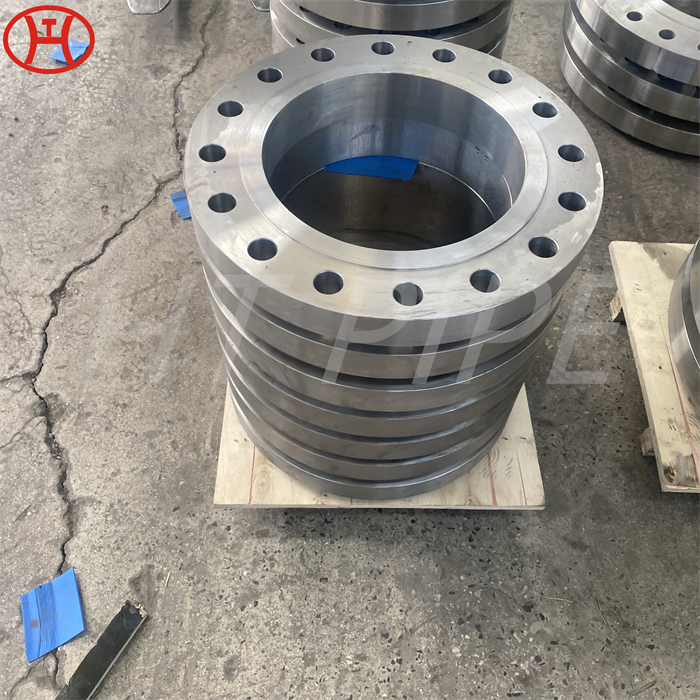

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Shipment & Transportation | By Road – Truck / Train, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| ASTM A790 UNS S32205 Duplex Stainless Steel Seamless Pipes Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |