duplex stainless steel seamless pipe fittings A815 stub end

Duplex stainless steels are a family of stainless steels. These are called duplex (or austenitic-ferritic) grades because their metallurgical structure consists of two phases, austenite (face-centered cubic lattice) and ferrite (body centered cubic lattice) in roughly equal proportions. They are designed to provide better corrosion resistance, particularly chloride stress corrosion and chloride pitting corrosion, and higher strength than standard austenitic stainless steels such as Type 304 or 316.

The main differences in composition, when compared with an austenitic stainless steel is that the duplex steels have a higher chromium content, 20¨C28%; higher molybdenum, up to 5%; lower nickel, up to 9% and 0.05¨C0.50% nitrogen. Both the low nickel content and the high strength (enabling thinner sections to be used) give significant cost benefits. They are therefore used extensively in the offshore oil and gas industry for pipework systems, manifolds, risers, etc. and in the petrochemical industry in the form of pipelines and pressure vessels. In addition to the improved corrosion resistance compared with the 300 series stainless steels duplex steels also have higher strength. For example, a Type 304 stainless steel has a 0.2% proof strength in the region of 280 N/mm2, a 22%Cr duplex stainless steel a minimum 0.2% proof strength of some 450 N/mm2 and a superduplex grade a minimum of 550 N/mm2.

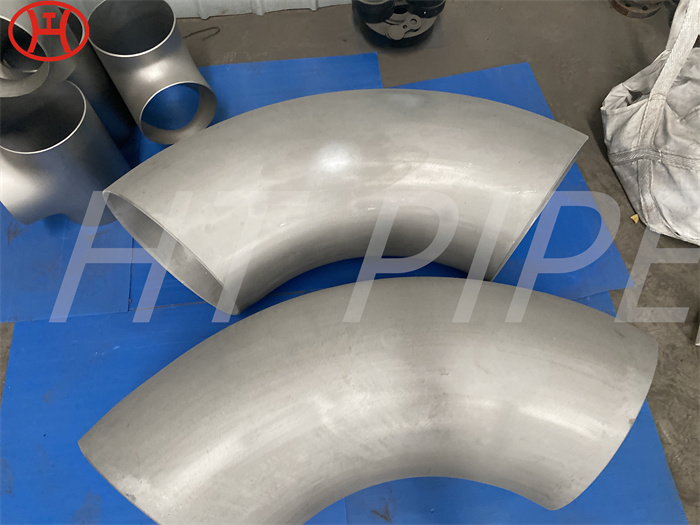

Type Long Radius Elbows,Long Radius Reducing Elbows,Long Radius Returns,Short Radius Elbows,Short Radius 180-deg Rerurns,3D elbows,Straight Tees,Straight Crosses,Reducing Outlet Tees,Reducing Outlet Crosses,Lap Joint Stub Ends,Caps,Reducers

Size OD: 1/2″ ~48″

Thickness: SCH5~SCHXXS

Manufacturing technique£ºpull, push

Producing Standard ASME B16.9 ASME B16.28 ASME B16.49 MSS SP-43 MSS SP-75

Material Stainless Steel ASTM/ASME SA 815 WPS31803, WPS32205, WPS32750, WPS32760, WPS32550