Duplex Steel ASTM SA 815 WPS32760 90 Degrees Elbow

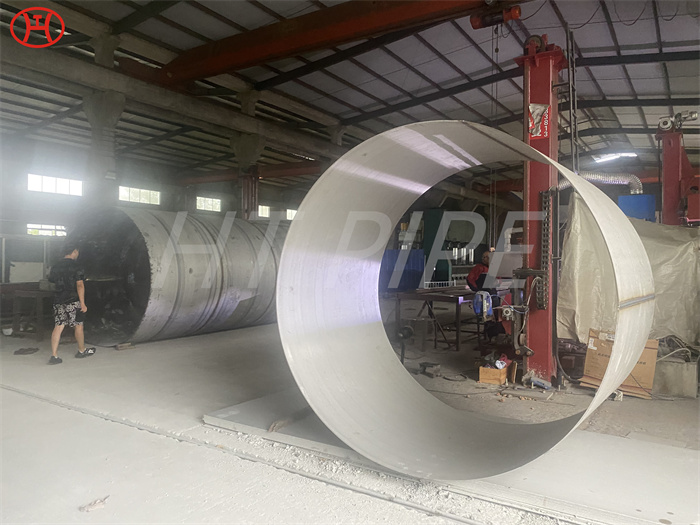

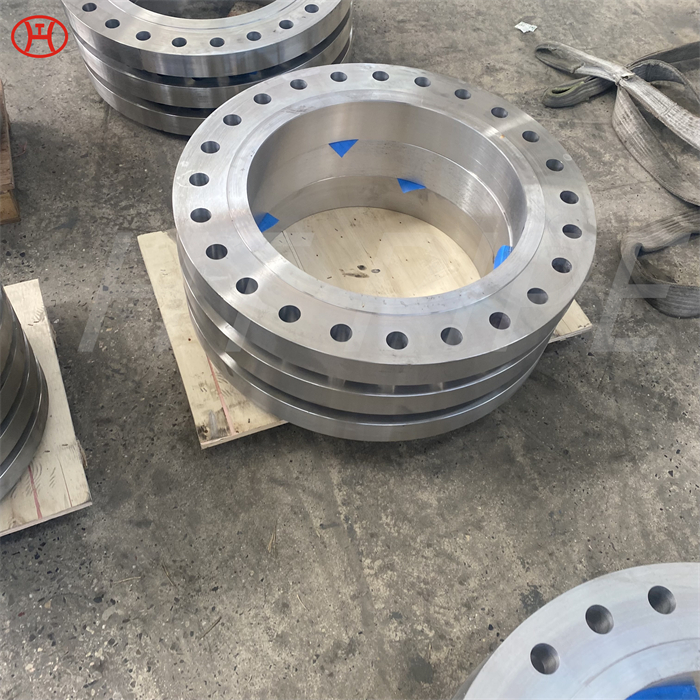

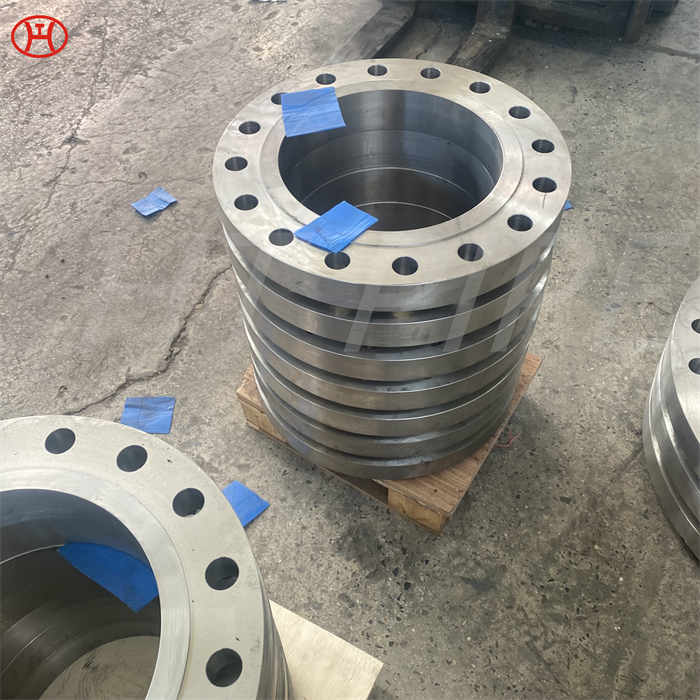

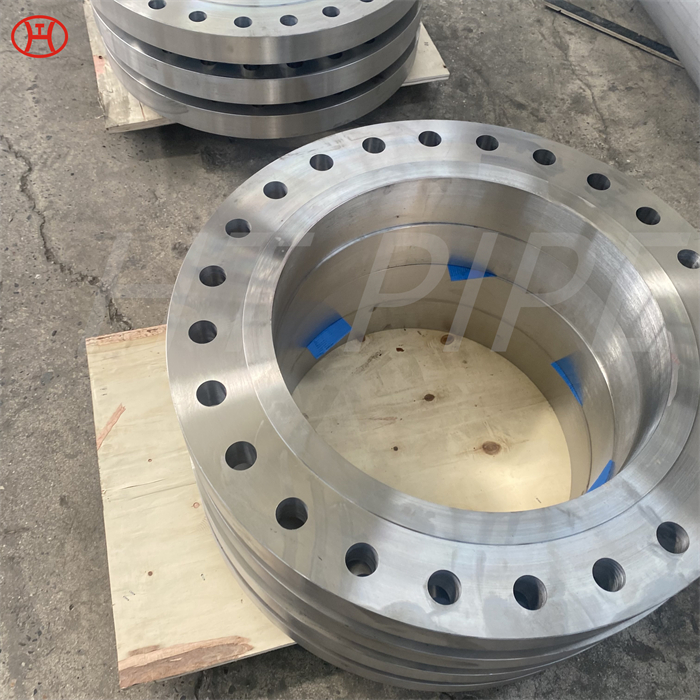

In order to convey the pipeline, it is necessary to remove the straight hose in the pipeline. When using various pipelines, various pipelines must be used. When the pipeline is used, the elbow must be used to change the size of the pipeline. When bifurcating, the three-way pipe The flange connection used when the joint is used with various pipe joints, in order to reach the long-distance transmission pipeline, in order to reach the thermal expansion and cold contraction joint or effective connection aging of the pipeline, the long-distance expansion and cold contraction joint is used for the connection of the pipeline. , In the connection of various instruments, there are also the connectors and plugs of the instrument phase.

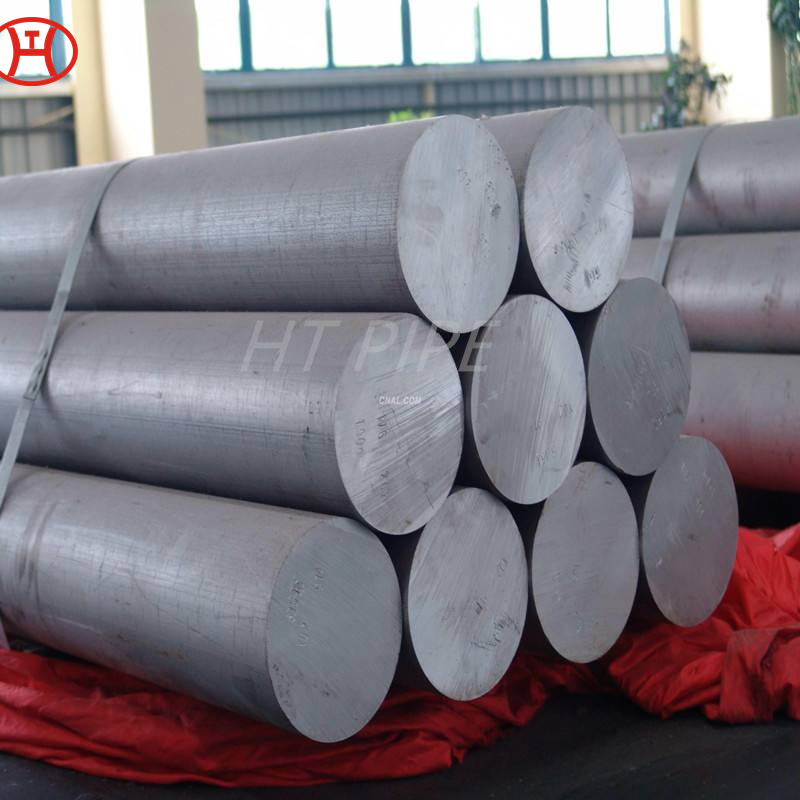

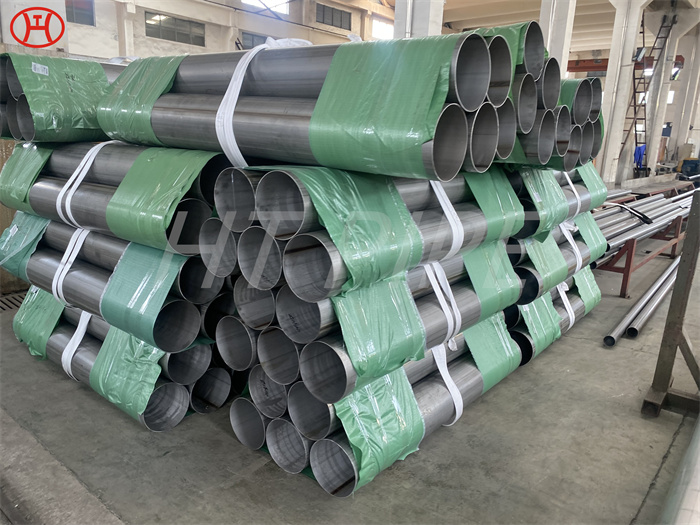

Duplex stainless steels are Fe-Ni-Cr alloys consisting of ferritic-austenitic microstructure at room temperature. These steels generally possess beneficial combinations of the austenitic and ferritic phases. Duplex stainless steels exhibit greater toughness and better weldability than ferritic stainless steel (Nilsson, 1992). They have higher strength and better corrosion resistance than austenitic stainless steel (Atamert and King, 1992). Their good engineering performance has led to an increasing number of applications, mainly in corrosive environments such as sour gas pipelines and chemical reaction vessels.

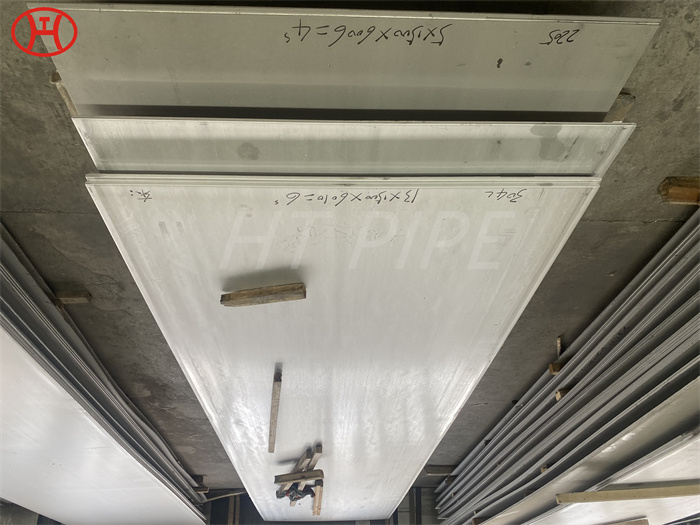

Duplex stainless steels combine characteristics of the austenitic and ferritic family of alloys to offer benefits from both with fewer downsides — often at a lower cost than other steel alloys.The UNS S32760 standard of pipe fittings is considered one of the best in the industry due to its mechanical properties. The UNS S32760 Pipe Fittings have high tensile strength, durability, and excellent corrosion resistive property. The ASTM A815 UNS S32760 Super Duplex Pipe Fittings can be used in various industries that operate in extreme environments and temperatures.