Duplex Steel UNS S31803 Seamless Pipes Suppliers

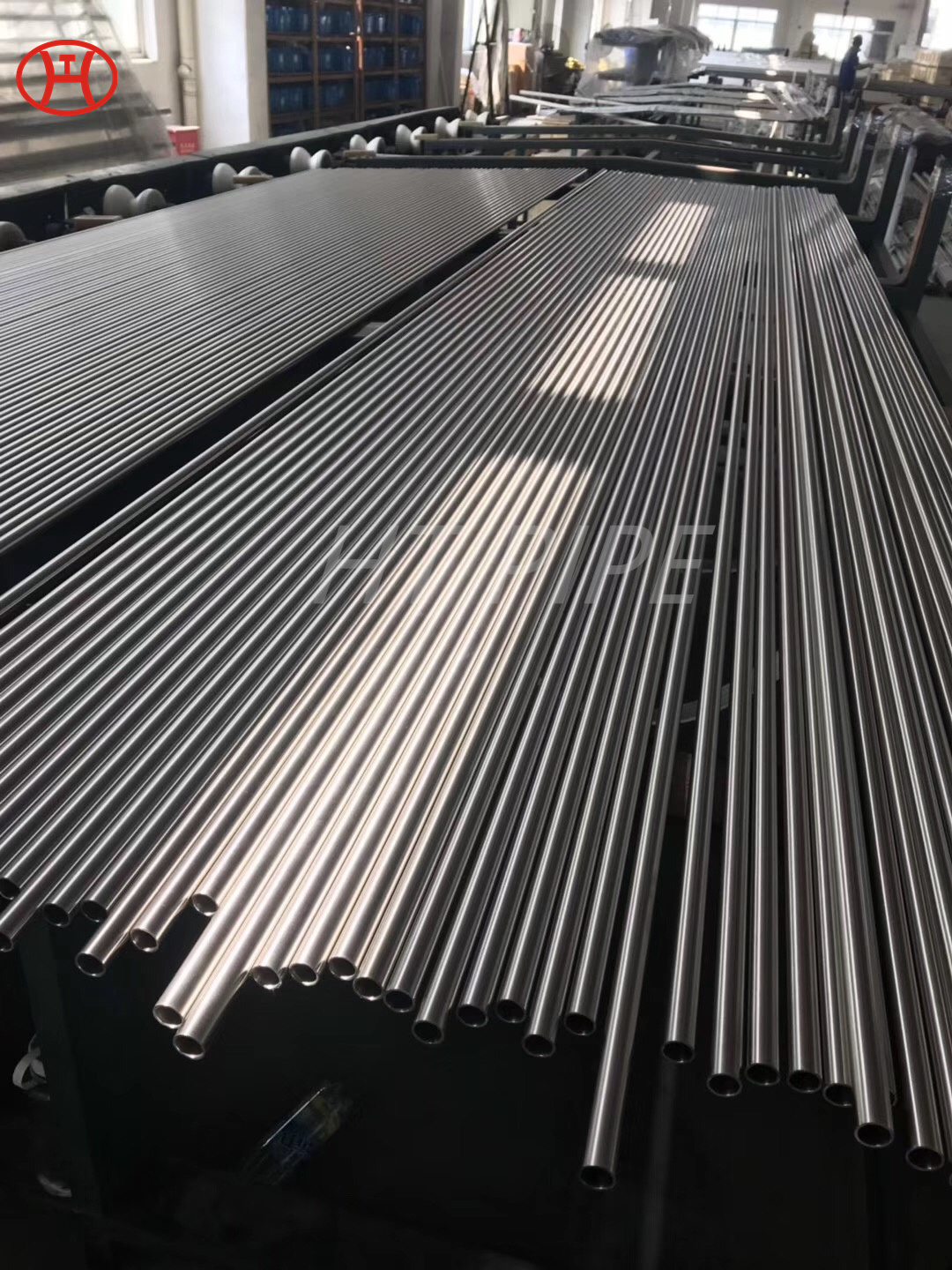

Duplex Steel UNS S31803 Seamless Pipes are widely used in various applications in the industry. These ASTM A790 Duplex Steel S31803 Pipes are made up of a combination of microstructure of austenitic and ferritic grains, which gives them unique properties. These properties include a high resistance to corrosion, excellent strength and toughness, and good weldability.

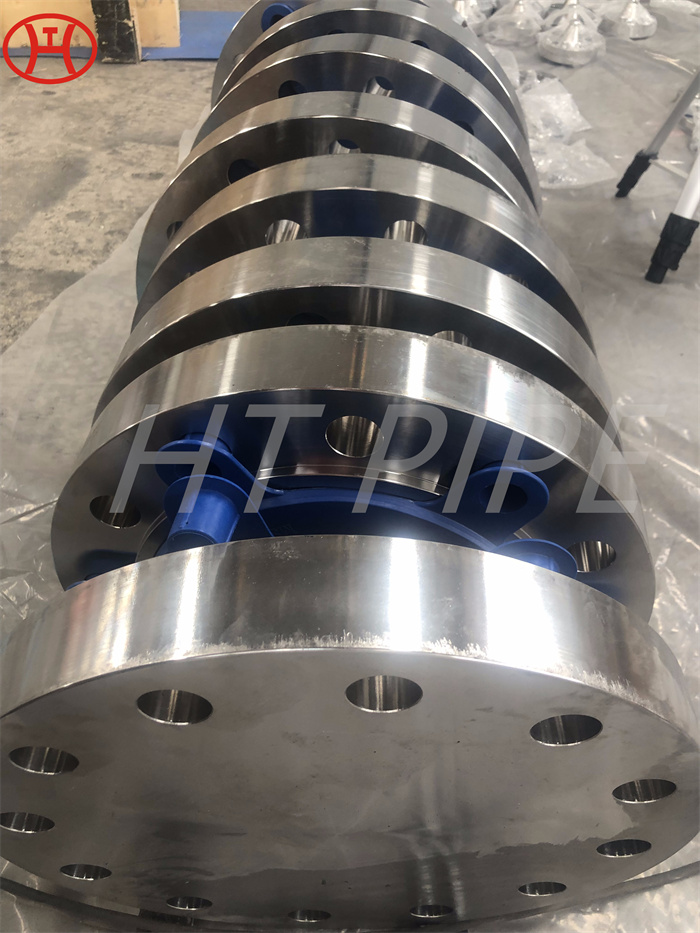

ASTM A790 Duplex Steel S31803 Pipes, Duplex Steel UNS S31803 Tubing, Duplex Steel 1.4462 Pipe, Duplex Steel UNS S31803 Tubes Suppliers, Duplex Steel S31803 Welded Pipes, Duplex Steel S31803 Tubes, Duplex Steel S31803 Seamless Pipes Manufacturer.

Duplex Steel UNS S31803 Seamless Pipes are widely used in various applications in the industry. These ASTM A790 Duplex Steel S31803 Pipes are made up of a combination of microstructure of austenitic and ferritic grains, which gives them unique properties. These properties include a high resistance to corrosion, excellent strength and toughness, and good weldability.

The UNS S31803 grade is a popular choice for seamless pipes due to its superior properties. It is highly resistant to stress corrosion cracking and has good resistance to pitting and crevice corrosion, making Duplex Steel UNS S31803 Tubing ideal for use in harsh environments.

Duplex Steel 1.4462 Pipe are commonly used in applications where high temperatures and corrosive environments are present. The oil and gas industry, chemical processing, and desalination plants are just a few examples. These Duplex Steel UNS S31803 Tubes provide a cost-effective solution for these demanding applications due to their high durability and long lifespan.

In addition to their excellent corrosion resistance, Duplex Steel S31803 Welded Pipes are also known for their good fatigue strength and impact resistance. This makes them suitable for use in applications where there may be high stress levels or where sudden and severe impacts may occur.

Duplex Steel S31803 Tubes are available in various sizes and thicknesses to suit different applications. Duplex S31803 Industrial Pipes can also be customized to meet specific needs and requirements. These pipes can be easily welded and fabricated, making installation and maintenance easy and hassle-free.

Duplex Steel UNS S31803 Seamless Pipes offer excellent corrosion resistance, durability, strength, and versatility, making them the ideal choice for a wide range of applications in the industry. Their unique combination of properties makes ASME SA 789 Duplex Steel S31803 Tubes a cost-effective solution for challenging environments, which require high-performing materials.

Chemical Composition S31803 Pipe

| Ni | Cr | Mo | Mn | Si | C | N | S | P | Fe |

| MIN | 4.5 | 22.0 | 3.0 | – | – | – | 0.14 | – | – |

| MAX | 6.5 | 23.0 | 3.5 | 2.0 | 1.0 | 0.03 | 0.2 | 0.02 | 0.03 |

Duplex S31803 Pipe Mechanical Properties

| S31803 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |