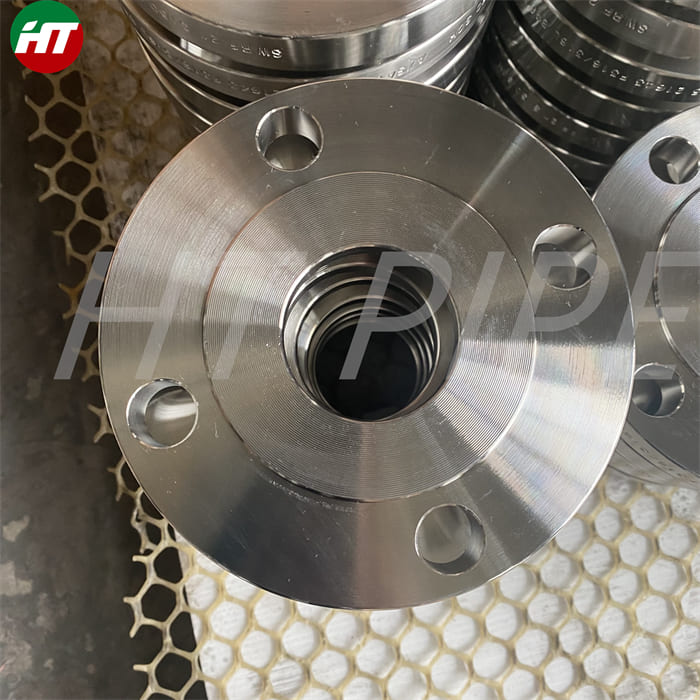

A105 Asme B16.5 600# Wn Rf 2576 Norsok Cs 8In Din Flange

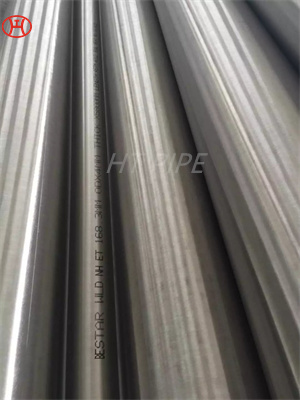

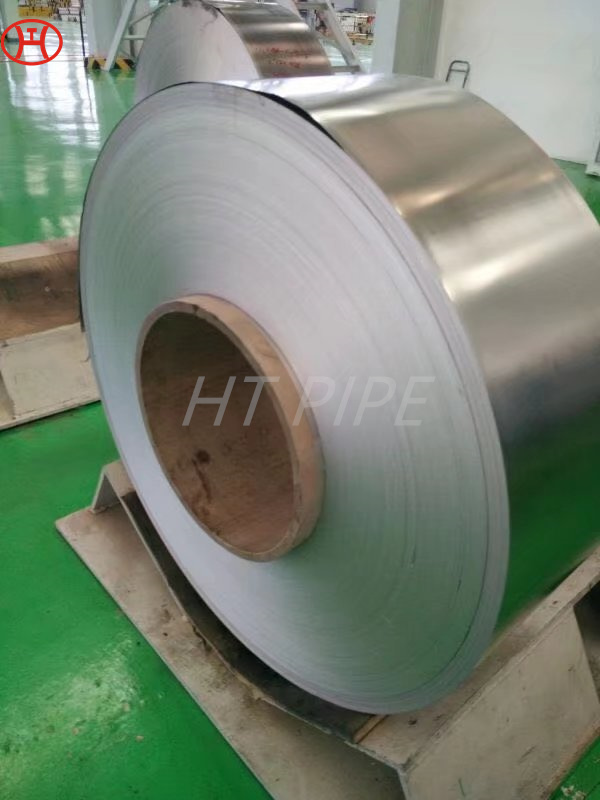

The forging process also consolidates the material to produce an essentially wrought steel structure. The product is subsequently machined to the exact shape and size of finished flange.

ASTM A105 / A105N Flanges , Carbon Steel Flanges, Manufacturer Of A105 Carbon Steel Plate Flange, ASTM A105 Carbon Steel Flanges, Best Price of ASTM A105 WNRF Flanges Exporter, Stockholder Of Carbon Steel RTJ Flange

ASTM A105 steel flanges that are manufactured by A105N material, where “N” symbolizes the heat treatment to the steel. ASTM A105 is the one of the common forged steel material used for manufacturing flanges. After heat treatment normalization, this A105 steel easily removes internal stresses caused due to forming, casting or forging. This heat treatment ensures A105 Carbon Steel Plate Flanges superior properties. These ASTM A105 Carbon Steel Flanges are used for high temperature and ambient services. ASTM A105 WNRF Flanges are hard and contain nickel content. Carbon Steel RTJ Flanges are used in various applications like a boiler, petroleum industry, shipbuilding and electric industry.

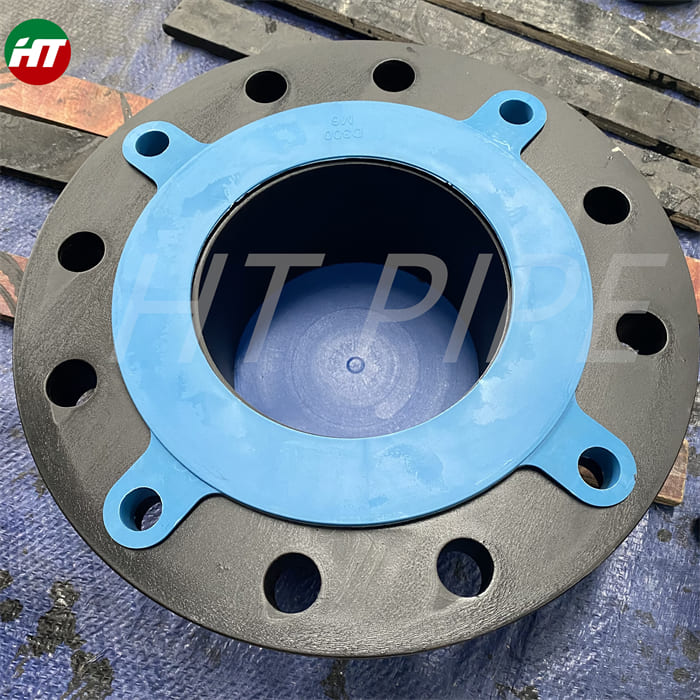

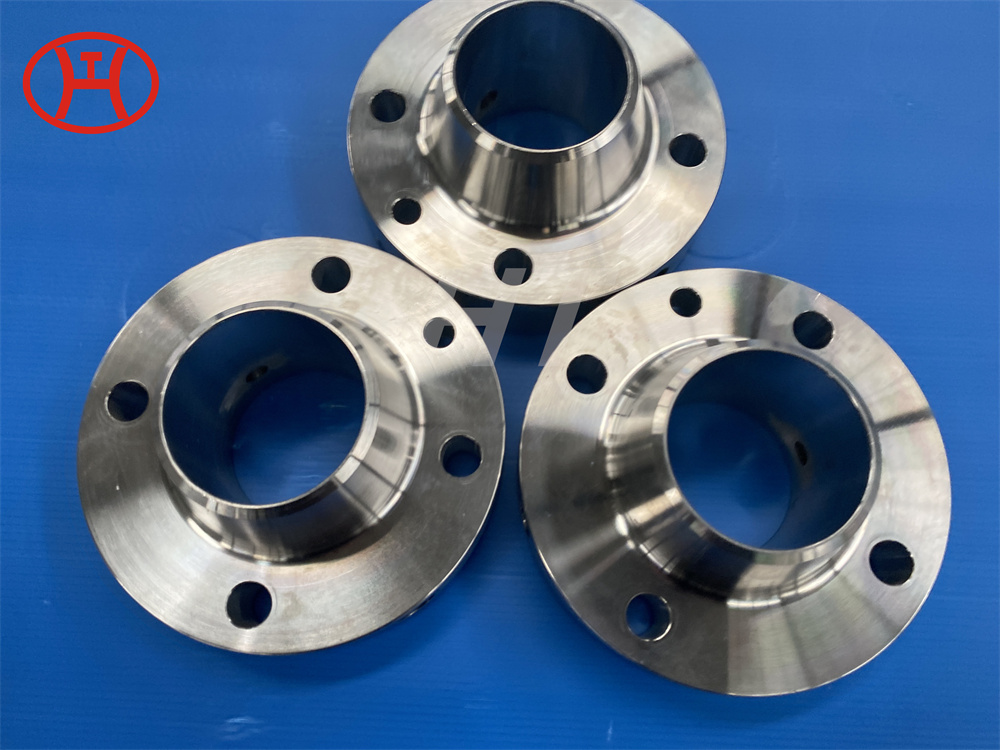

There are various types of ASTM A105N flanges, available such as WN welding neck, SO slip-on, TH threaded, LF lapped stub end, orifice flange, and long welding neck. The material used for making these flanges is ASTM A105 steel; these flanges meet both international and national standards like ASME, ANSI B16.5, and MSS SP44. They are manufactured and well coated with black paint, oil coating to prevent it from rusting. You can easily use them at different pressure levels such as CLASS 150, CLASS 600 and CLASS 2500. Beside those ASME and ANSI standards, these flanges are manufactured in other standards also. ASTM A105N flanges are tested and inspected by inspection agencies. Customers are provided the proper mill test certificate and packing list. ASME SA105N Carbon Steel Class 300 Flanges are packed in wooden cases, plywood boxes or seaworthy packages to prevent flanges from any kind of damages.

The forged carbon steel conforming to ASTM A105 is a Group 1.1 material according to ASME B16.5. Generally, heat treatment for A105 flanges in Class 150 and Class 300 is not necessarily required. For flanges above Class 300 or otherwise specified by end user, heat treatment, such as annealing, normalizing, or normalizing and tempering, or quenching and tempering, may be performed.

Standard Specification For ASTM A105N Flanges

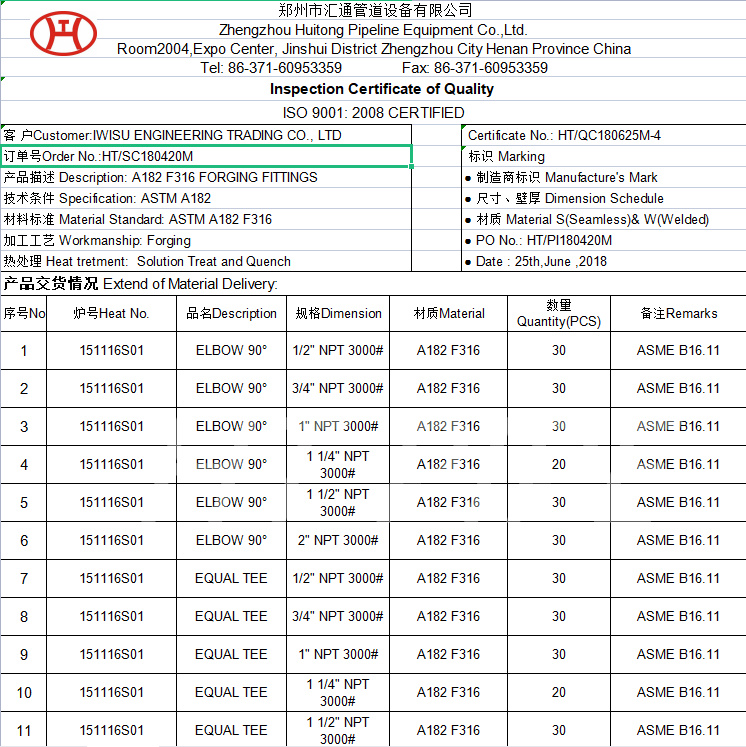

| Specification | ASTM A105N / ASME SA105N |

| Dimensions | ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631–2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, TABLE D, TABLE E, TABLE F, TABLE J etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Size | 1/2″ to 48″ |

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Types | ASTM A105N Slip On Flange, ASTM A105N Socket Weld Flange, ASTM A105N Threaded / Screwed Flange, ASTM A105N Orifice Flanges, ASTM A105N SORF Flange, ASTM A105N Welding Neck Flange, ASTM A105N Long Welding Neck Flanges, ASTM A105N SWRF Flange, ASTM A105N Custom Flange as per Drawing etc., ASTM A105N Weldoflange, ASTM A105N Expander Flange, ASTM A105N Nipoflange, ASTM A105N Reducing Flange, ASTM A105N Plate Flange, ASTM A105N WNRF Flange, ASTM A105N Blind Flange, ASTM A105N Lap Joint Flange, ASTM A105N Pipe Flange |

| Value Added Services | CNC Machining, Cold and Hot Dip Galvanized, Yellow Transparent, Drill, Oil Black Paint, Rolling, Zinc Plated, Anti-rust Paint, Shot Blasting, Sand Blasting, Heat Treatment, Punch |

| Other Testing | Carbon Equivalent, Hardness, Grain Size, A for annealed, NT for Normalized and Tempered, N for normalized, NACE MR0175, Macro, SSC, or QT for Quenched and Tempered, Ultrasounic Test, HIC, Sour Service, Charpy Impact Test etc. |