Forged round din 14541 04 ss 304 rod 7mm 316 stainless steel flat bar

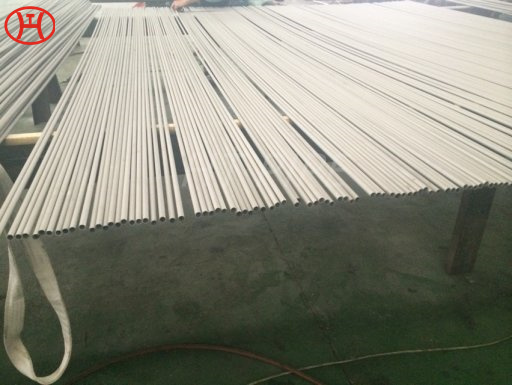

Some of the properties found in these stainless steel round bars are excellent general corrosion resistance, resistance to sensitization, ease of manufacture, good formability, high tensile strength, robust construction, corrosion resistant body, long service life, high temperature resistance, Good dimensional accuracy and surface smoothness finish. In our high-operations manufacturing, the development of high-grade round bars is done under the appropriate supervision of a team of dedicated experts.

S30400 round bar is one of the most widely utilized 18/8 stainless steel alloys in existence. Industrial Metal Supply offers ASTM A479 UNS S30400 Rod in a wide range of diameters to fit your exact application needs. With over 400,000 total square feet of warehouse and storage space in China, the UNS S30400 Round Bar Manufacturer HT PIPE has the capacity and capabilities to service your ASTM A276 Type 304 bar stainless steel needs.

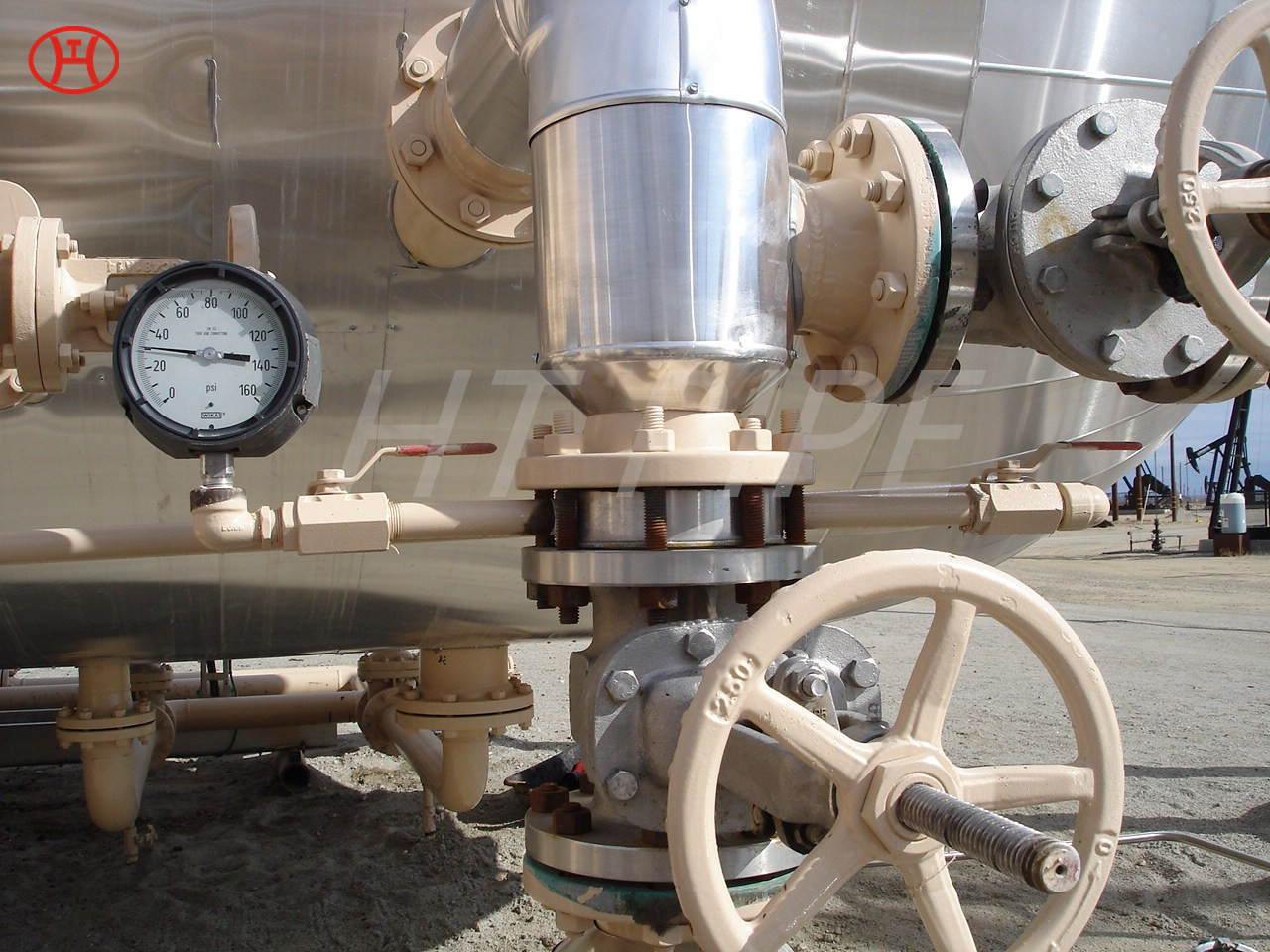

304 is the most versatile and widely used of all stainless steels. Its chemical composition, mechanical properties, weldability and corrosion/oxidation resistance provide the best all-round performance stainless steel at relatively low cost. Stainless Steel 304 Round Bar also has excellent low-temperature properties and responds well to hardening by cold working. If the potential for intergranular corrosion in the heat-affected zone exists, 304L is recommended. ASTM A276 304 Stainless Steel Bar is a versatile, anti-rusting and heat resistant steel for general use. And it is used mainly in the building, plumbing and chemical industries.

The passivated oxide layer formed on the surface of 304 SS Round Bar prevents decay by oxidation. The free chromium present on the surface of these bars reacts with oxygen to form a self-healing layer on the S30400 round bar, thereby effectively preventing the 304 SS Bar from getting corroded by oxidation. However, amongst all the attractive properties, what really stands out is that the SS 304 Flat Bar can be used in cryogenic environments. Unlike some alloy steels or some stainless steel grades, the 304 SS Flat Bar is able to retain properties such as excellent mechanical strength as well as toughness, despite exposure to cryogenic temperatures.

Stainless Steel 304 Round Bar Range

| SS 304 Round Bar Specification | ASTM A276 / ASTM A479 /ASTM A182 / ASME SA276 / ASME SA479 / ASME SA182 |

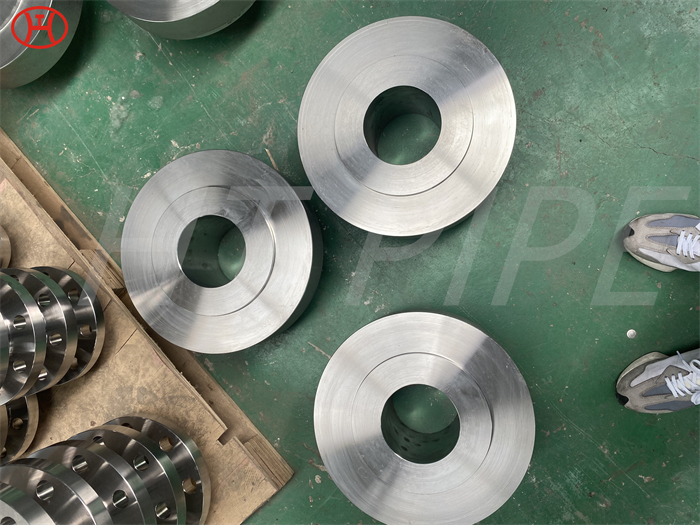

| SS 304 Round Bar Manufacturing Process | Hot Rolled / Cold Rolled / Hot Forging / Rolling / Machining |

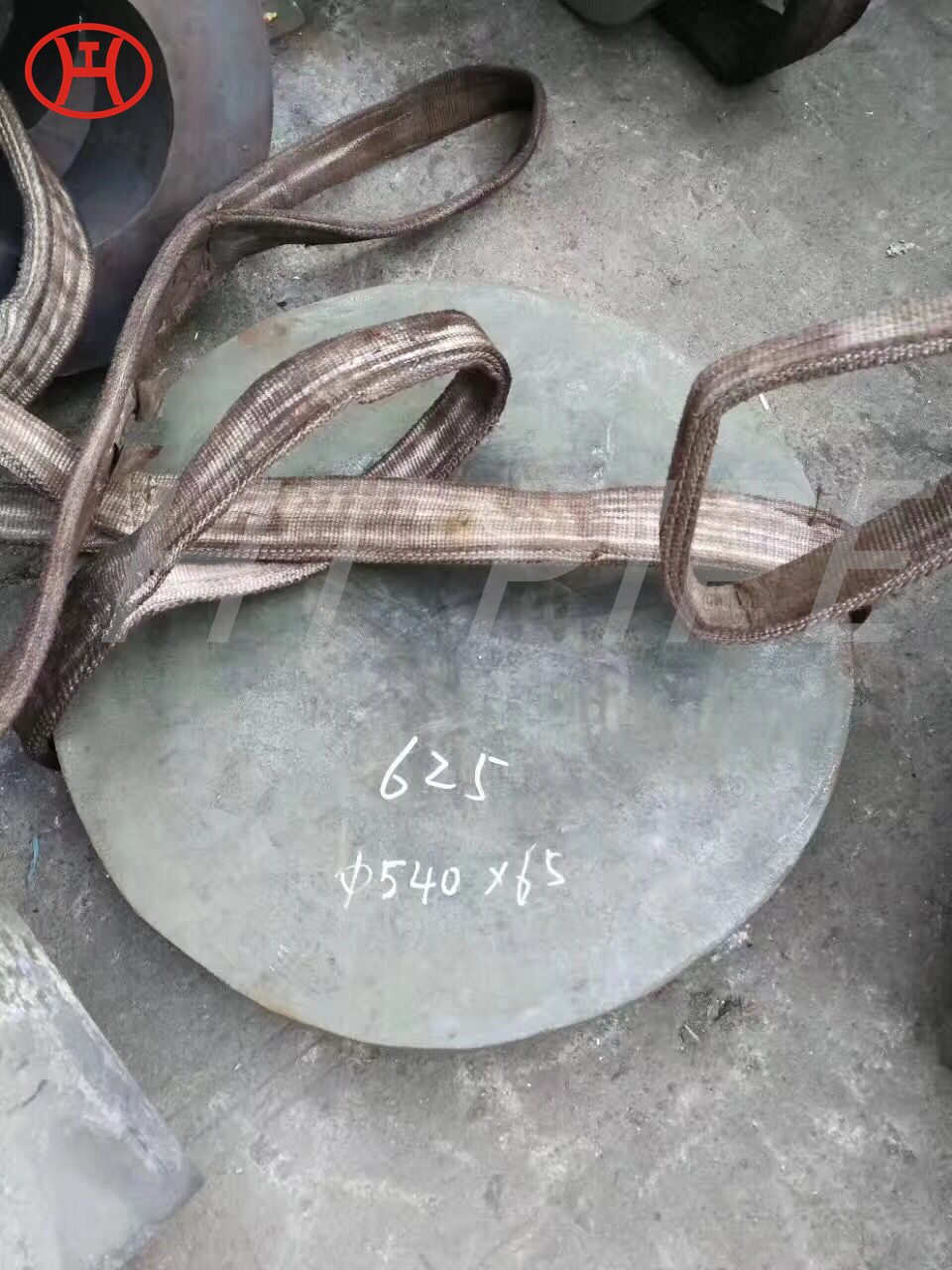

| SS 304 Round Bar Other Grades | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. UNS No. – UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 DIN / EN No. – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 AFNOR: Z2 CN 18.10, Z 6 CND 17-11, Z 2 CND 17-12,Z3 CrNi 22.05 AZ EURONORM: FeMi35Cr20Cu4Mo2, FeMi35Cr20Cu4Mo2, X1CrNiMo17 12 2, X3CrNiMo17 12 2, FeMi35Cr20Cu4Mo2, X2CrNiMoN 22.5.3 |

| SS 304 Round Bar Dimension | Round Bars : Outside Diameter in the range of 4mm to 500mm Bright Bars : Outside Diameter in the range of 4mm to 200mm Hex Bars : 18mm – 57mm (11/16″ to 2-3/4″) Square Bars : 18mm – 57mm (11/16″ to 2-3/4″) Flat Bars : 1/2” to 10” in thickness range of 2mm to 150mm, Custom Size Stainless Steel Flats available |

| SS 304 Round Bar Length | 2 meters – 7.5 meters ( 8 feet to 24 feet), or Custom Length as per Requirement |

| SS 304 Round Bar Forms and Shape | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, HRAP, Bright, Forging Etc. |

| SS 304 Round Bar Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| SS 304 Round Bar Dimension Standard | ASTM A 484 / ISO h11 / ISO K12 Tolerances F8 / h8, h9, h10, h11, h12, k12, k13, A-484, EN-10060, DIN-1013 etc. |

| SS 304 Round Bar Heat Treatment | Condition A in which the bars are Annealed Condition H in which the bars are Hardened and Tempered at a relative Temperature Condition T in which the bars are Hardened and Tempered at a relatively High Temperature Condition S in which the bars are Strain Hardened or relatively Light Cold Worked Condition B in which the bars are Relatively severe Cold worked. Solution Annealed, Aging and Double Aging |

| SS 304 Round Bar Surface Finish | Centreless Ground & Belt Polished, up to Ra value = 0.2 um (12 RMS), and Grit Polished of up to 180 to 600 |

| SS 304 Round Bar Chamfering | Available in 30°, 45° & 60° through fully automatic, both-end chamfering machine |

| SS 304 Round Bar Other Testing | NACE MR0175, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, Magnetic Particle Inspection (MPI), 100% tested thru Digital Ultrasonic Flaw Detector, as per ASTM A-388, EN 10308 (class 1to4),API 6A/ISO 10423:2003-PSL3,SEP 1920:1984 ( class A,B,C), MIL STD 2154 etc. |

| SS 304 Round Bar Value Added Services | Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Polishing |

| SS 304 Round Bar Packaging | Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps |

| S304 Round Bar Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| SS 304 Round Bar Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC |

| SS 304 Round Bar Documentation | Commercial Invoice which includes HS Code / Packing List including net weight and gross weight, number of boxes, Marks and Numbers / Certificate of Origin legalized/attested by Chamber of Commerce or Embassy / Fumigation Certificates / Raw Material Test Reports / Material Traceability Records / Quality Assurance Plan (QAP) / Heat Treatment Charts / Test Certificates certifying NACE MR0103, NACE MR0175 / Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 / Guarantee Letter / NABL approved Laboratory Test Reports / Welding Procedure Specification/Procedure Qualification Record, WPS/PQR / Form A for the purposes of the Generalized System of Preferences (GSP) |