Galvanizing ASME B16.5 Flanges Stainless Steel Flange

SAE 304 stainless steel is the most common stainless steel. The steel contains both chromium (between 18% and 20%) and nickel (between 8% and 10.5%)[1] metals as the main non-iron constituents. It is an austenitic stainless steel. It is less electrically and thermally conductive than carbon steel. It is magnetic, but less magnetic than steel. It has a higher corrosion resistance than regular steel and is widely used because of the ease in which it is formed into various shapes.[1]

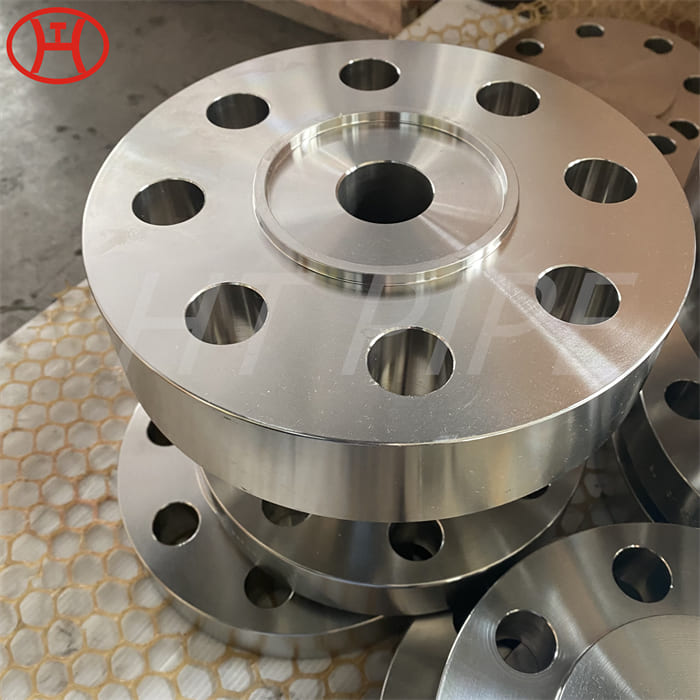

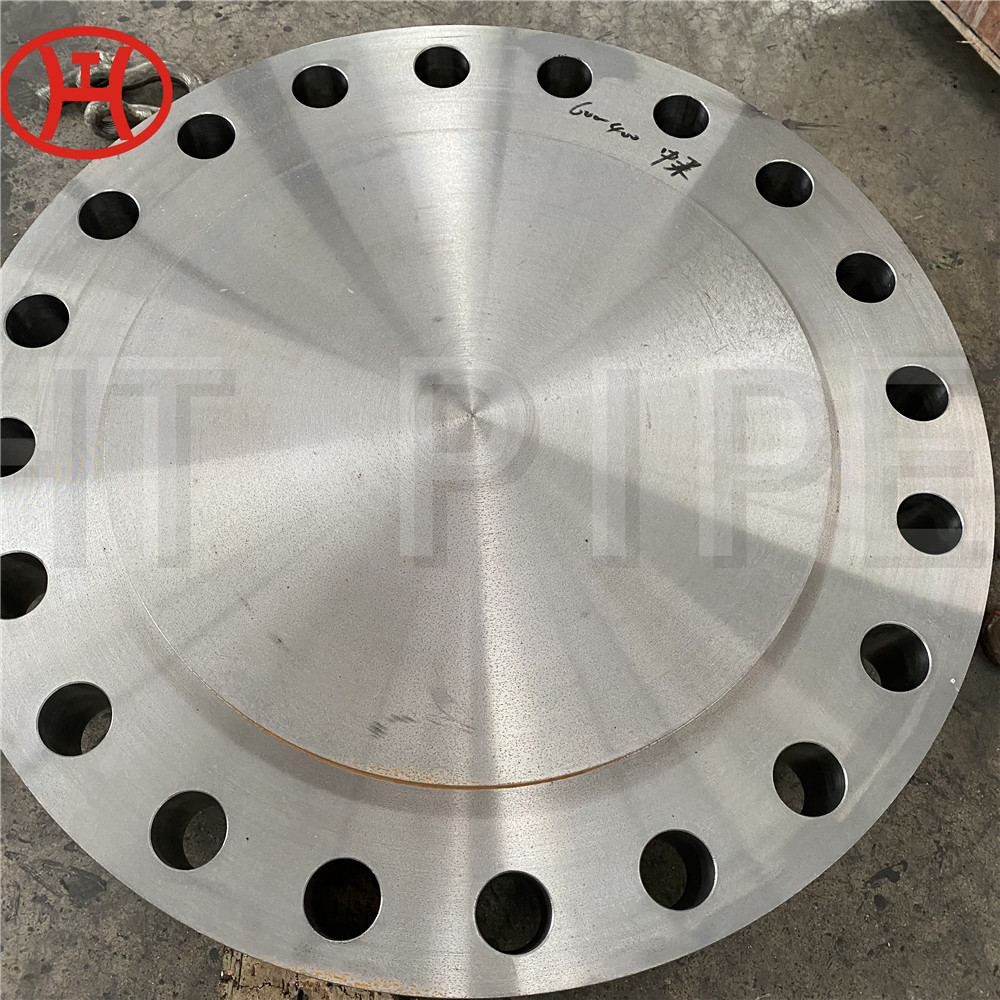

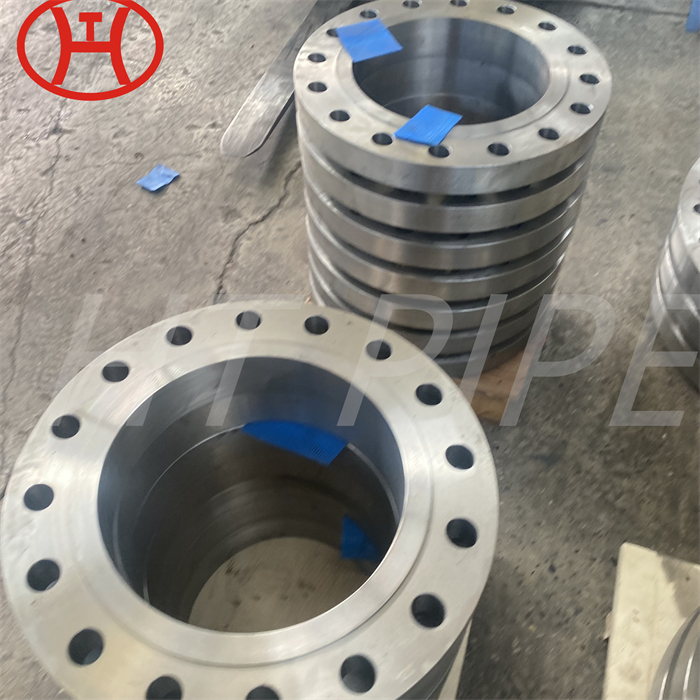

Stainless steel flanges connect with pipe and fittings to form a piping system that delivers air, water, natural gas, oil, and steam in plumbing applications and food and dairy processing. Flanges provide easy access for cleaning, inspection, and modification. Flange types including blind, butt weld, lap joint, slip-on, socket weld, and threaded, are available in a variety of sizes and shapes. Stainless steel is durable, resists corrosion from caustic chemicals, corrosive fluids, oils, and gases, and withstands pressure and high temperatures.

We carry a large inventory of 304 and 316 stainless steel flanges in many types and sizes. Select from stainless pipe flanges such as: stainless steel blind plate flanges, stainless raised face blind flanges, stainless lap joint flanges, stainless steel slip on plate flanges, raised face socket weld flanges, raised face threaded flanges, raised face weld neck flanges, and raised face slip-on flanges.