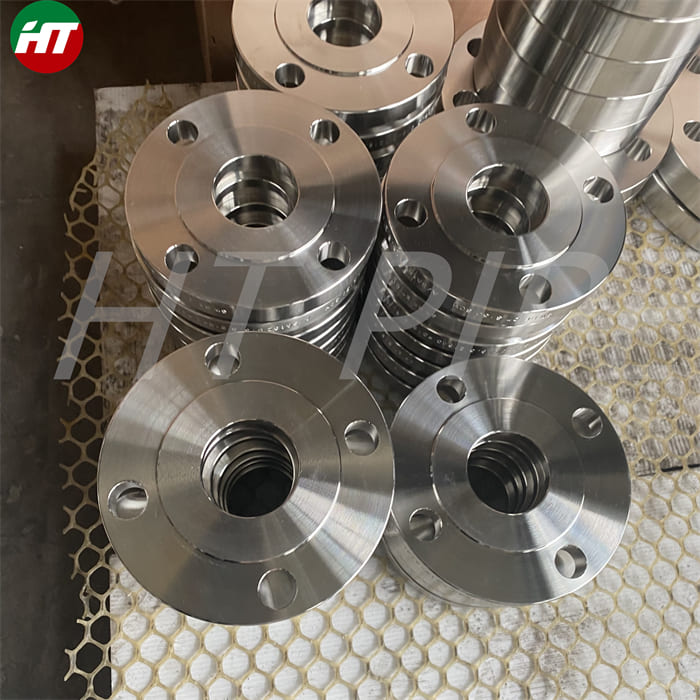

Hastelloy Alloy X Threaded Flanges Hastelloy N10665 Flanges

These alloys of flanges are basically non-magnetic but feature superior higher strength at a temperature range of 1500 degree F. whereas show good oxidation resistance up to 2200 degree F.

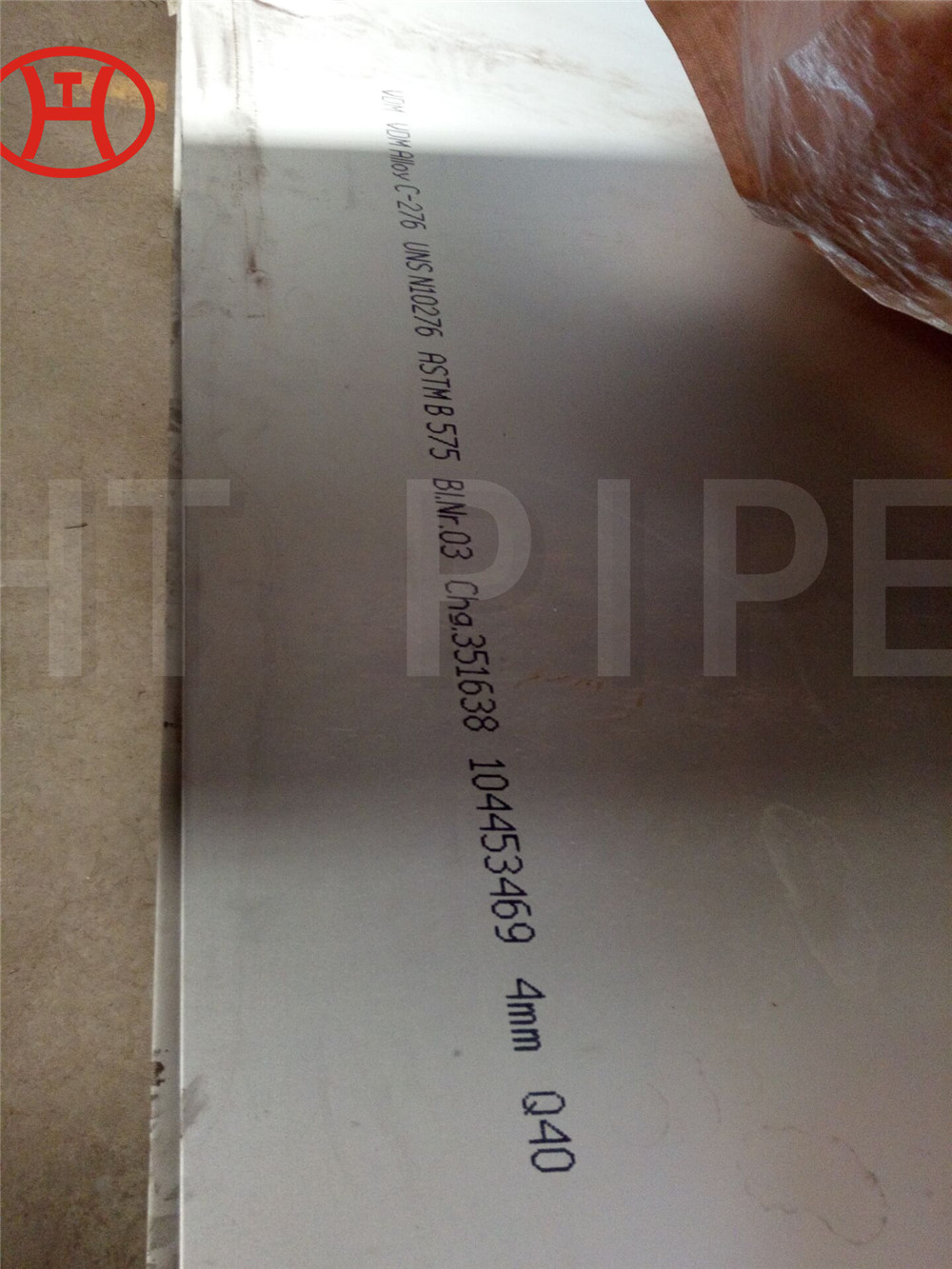

Hastelloy X Flanges is heat and corrosion-resistant nickel-based primary solid solution strengthened alloy. Hastelloy X is also referred to by its trade names ¨C INCONEL Alloy X or UNS N06002. This wrought nickel based alloy is used to make heat resistant flanges. Hastelloy X Flanges made of grade X hastelloy which is one of the most widely used nickel-based alloys due to its high resistance to oxidation and high temperature strength. A highlight of these flanges is that they exhibit excellent strength at high temperature as well as have good resistance to oxidation. The high content of chromium in the alloy aids in resistance against oxidation corrosion, whereas the higher content of nickel used to manufacture the Alloy X Blind Flange in accordance with ASTM B564 specification results in the alloy inheriting its heat resistance properties. Also known as Alloy ¡°X¡±, is commonly used in gas turbine engine components, furnace applications and any type of combustion zone sections such as tailpipes, cabin heaters and heat-treating equipment.