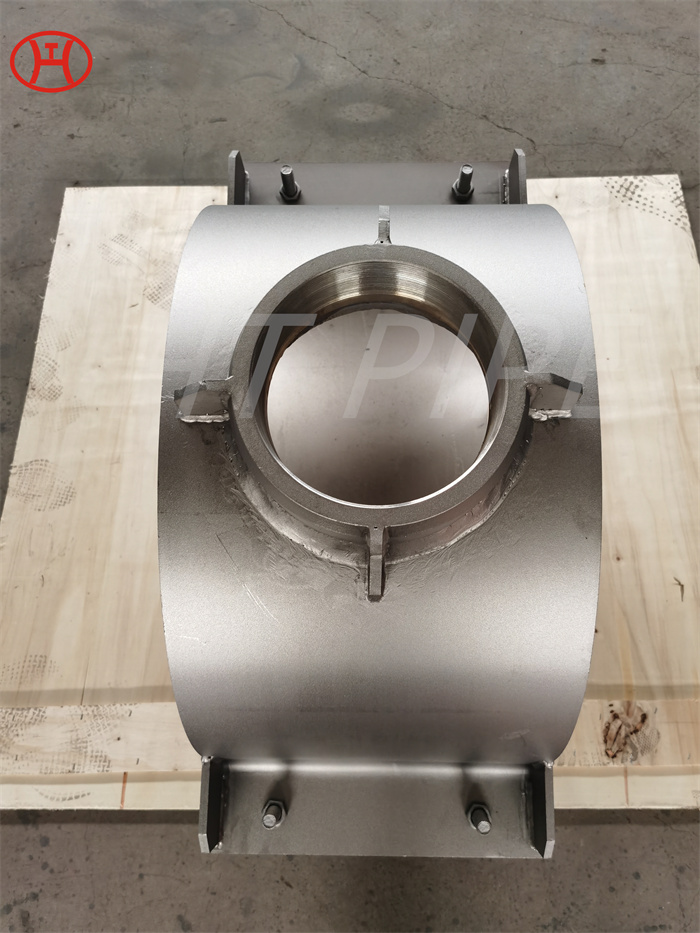

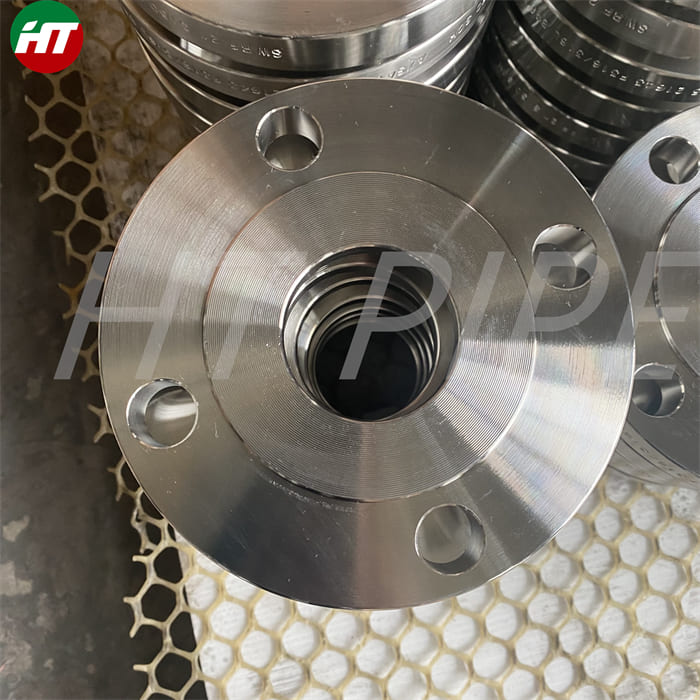

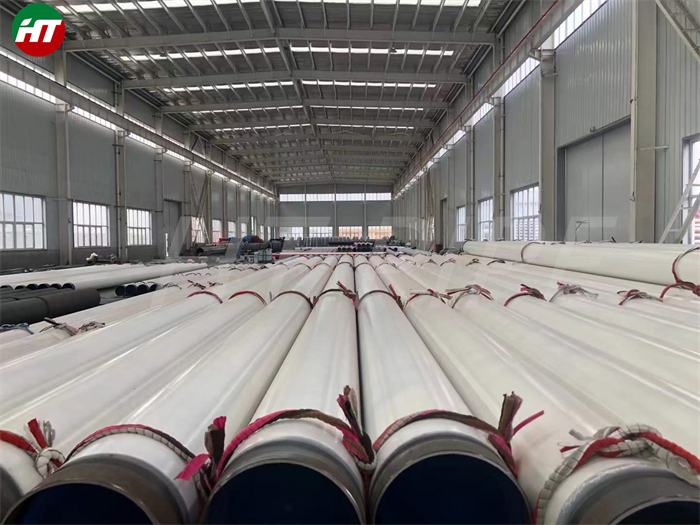

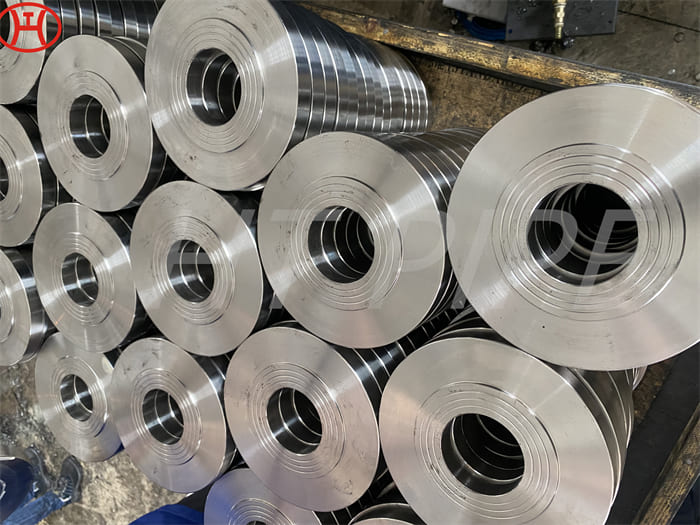

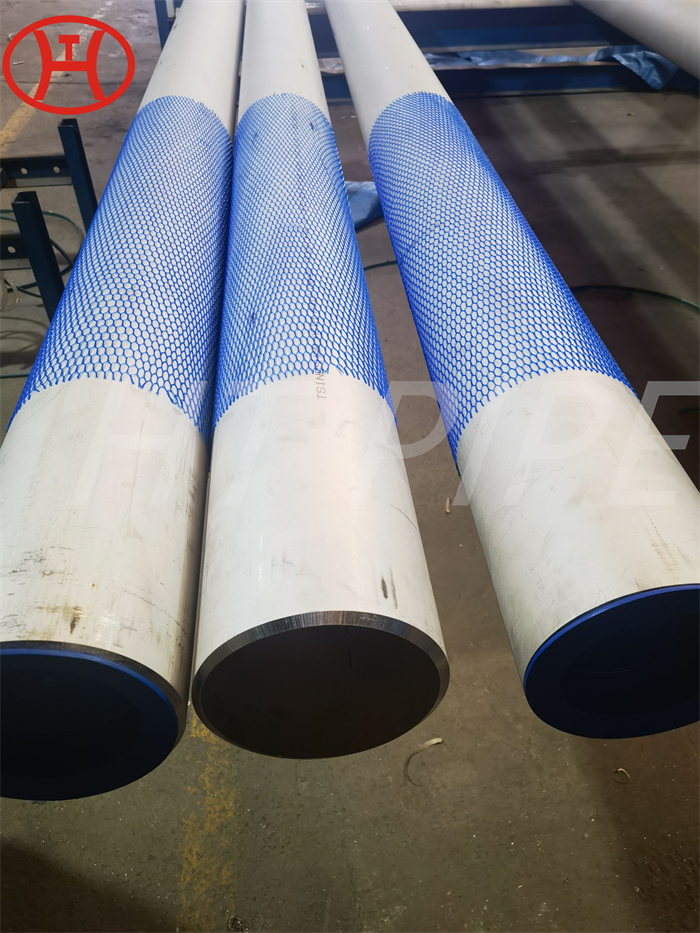

Hastelloy B2 pipe bend 2.4819 Alloy C 276 bw pipe fittings highly resistant to chlorine related stress corrosion cracking

Superior resistance to hydrochloric acid, aluminum chloride catalysts and other strongly reducing chemicals. Excellent high-temperature strength in inert and vacuum atmospheres.

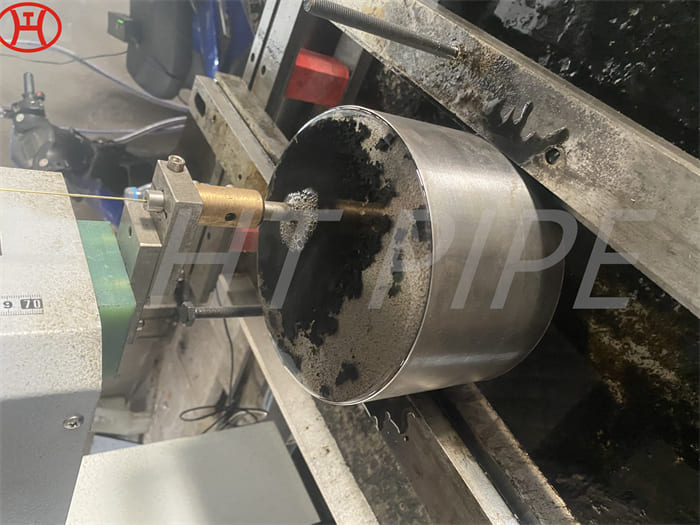

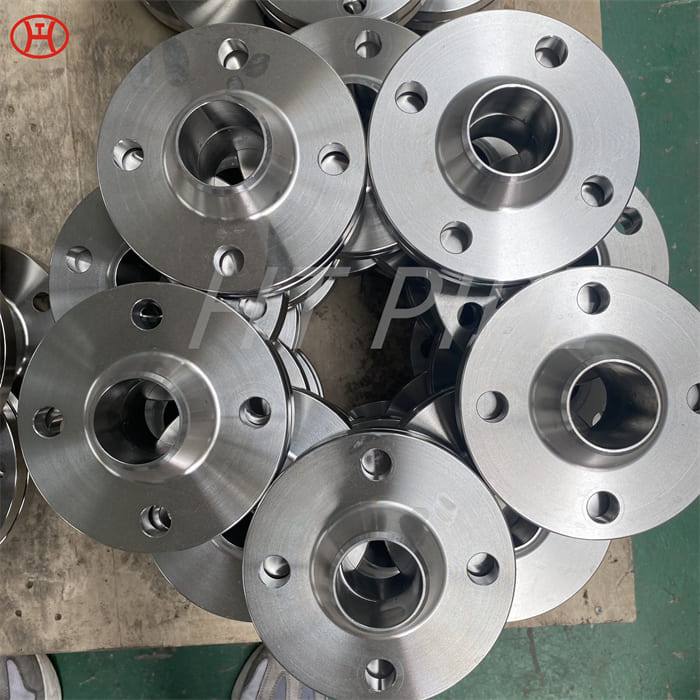

Hastelloy B2 pipe bends are mostly utilized for their excellent resistance to reducing environments like hydrogen chloride gas, sulfuric, acetic and phosphoric acids. HASTELLOY B-3 alloy (UNS N10675) exhibits extremely high resistance to pure hydrochloric, hydrobromic, and sulfuric acids. Furthermore, it has greatly improved structural stability compared with previous B-type alloys, leading to fewer concerns during welding, fabrication, and service. The chemical composition of Hastelloy B2 pipe bend includes a very small amount of carbon content. Hence, the flanges produced from Hastelloy grade B2 tends to resist the formation of grain boundary carbide precipitates during welding in the weld heat-affected zone. Alloy B-2 is a solid solution strengthened, nickel-molybdenum alloy typically used in extreme reducing conditions. Alloy B-2 pipe bend has signi?cantly lower carbon, silicon and iron compared to the predecessor, alloy B (UNS N10001).