Hastelloy B2 pipe bend at all concentrations and temperatures

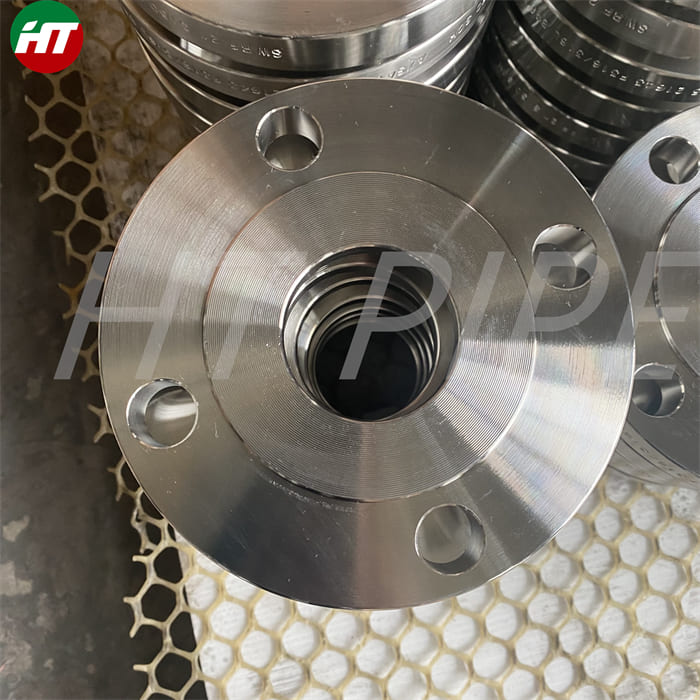

This nickel steel alloy can be used in the as-welded condition because it resists the formation of grain-boundary carbide precipitates in the weld heat-affected zone.

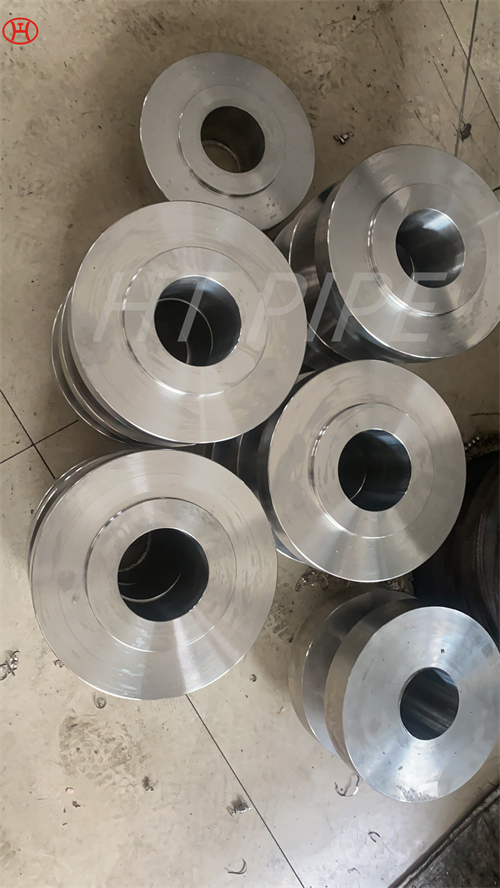

This grade possesses superior strength, and the Hastelloy B2 material used in producing them has excellent mechanical properties. They have a minimum tensile strength of 760Mpa and a minimum yield strength of 350Mpa. Apart from this, they can be easily machined and elongated up to 40%. As a nickel-molybdenum alloy, Hastelloy B2 has excellent resistance to reducing agents such as hydrogen chloride, sulfuric, acetic, and phosphoric acid. Purified sulfuric acid and other non-oxidizing acids are resistant to Hastelloy B2. The alloy should not be used in oxidising or reducing media containing oxidising contaminants. Using alloy B2 in a system containing hydrochloric acid can cause premature failure. The resistance to a wide range of organic acids and chloride-induced stress-corrosion cracking makes it popular among industrial users.