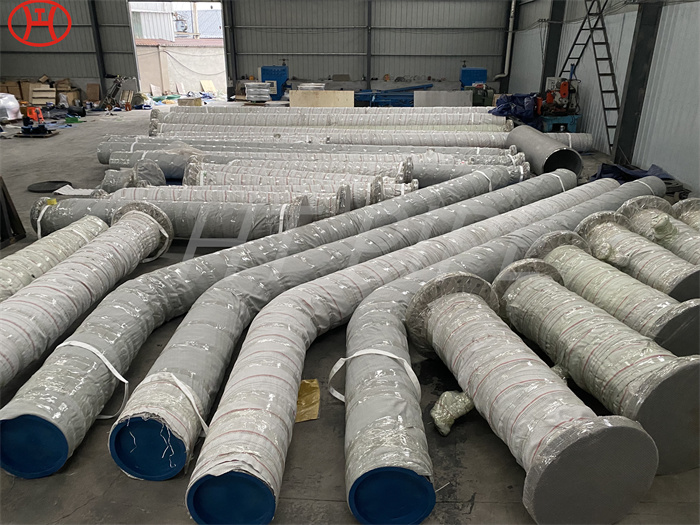

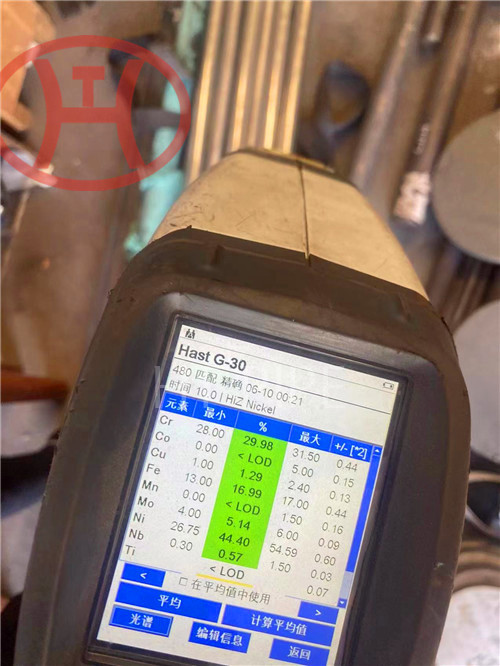

Hastelloy B2 pipe bend EN 10204 3.1 ASME B16.9 Buttweld Fittings

Hastelloy B2 pipe bend has excellent resistance to all temperatures and concentrations of hydrochloric acid.

Hastelloy B2 pipe bend are being supplied, manufactured and traded by Triton Metal to our esteemed patrons in best possible rates. Hastelloy B2 Rings (UNS N10276) can be forged, hot-upset and impact extruded. Oxyacetylene welding should be avoided due to possibility of carburization. Alloy B2 pipe bend resists chloride stress corrosion cracking even in boiling magnesium chloride. Besides hydrochloric acid, the ASTM B622 specified Hastelloy WERKSTOFF NR. 2.4617 Pipe has good resistance to medium concentrated sulphuric acid even when the solution has been with limited chloride contamination. The ASTM B622 hastelloy b2 pipe bend could also be used in acidic settings, especially ones that contain acids such as acetic acid and phosphoric acids, and to a wide range of organic acids. Uniform corrosion rates in various environments are similar compared to the other nickel-molybdenum alloys such as alloy B-3. The presence of any oxidizing media, even in trace amounts, will signi?cantly increase corrosion. Alloy B-2 pipe bend should not be used in oxidizing media, as these alloys show little to no resistance in such environments.