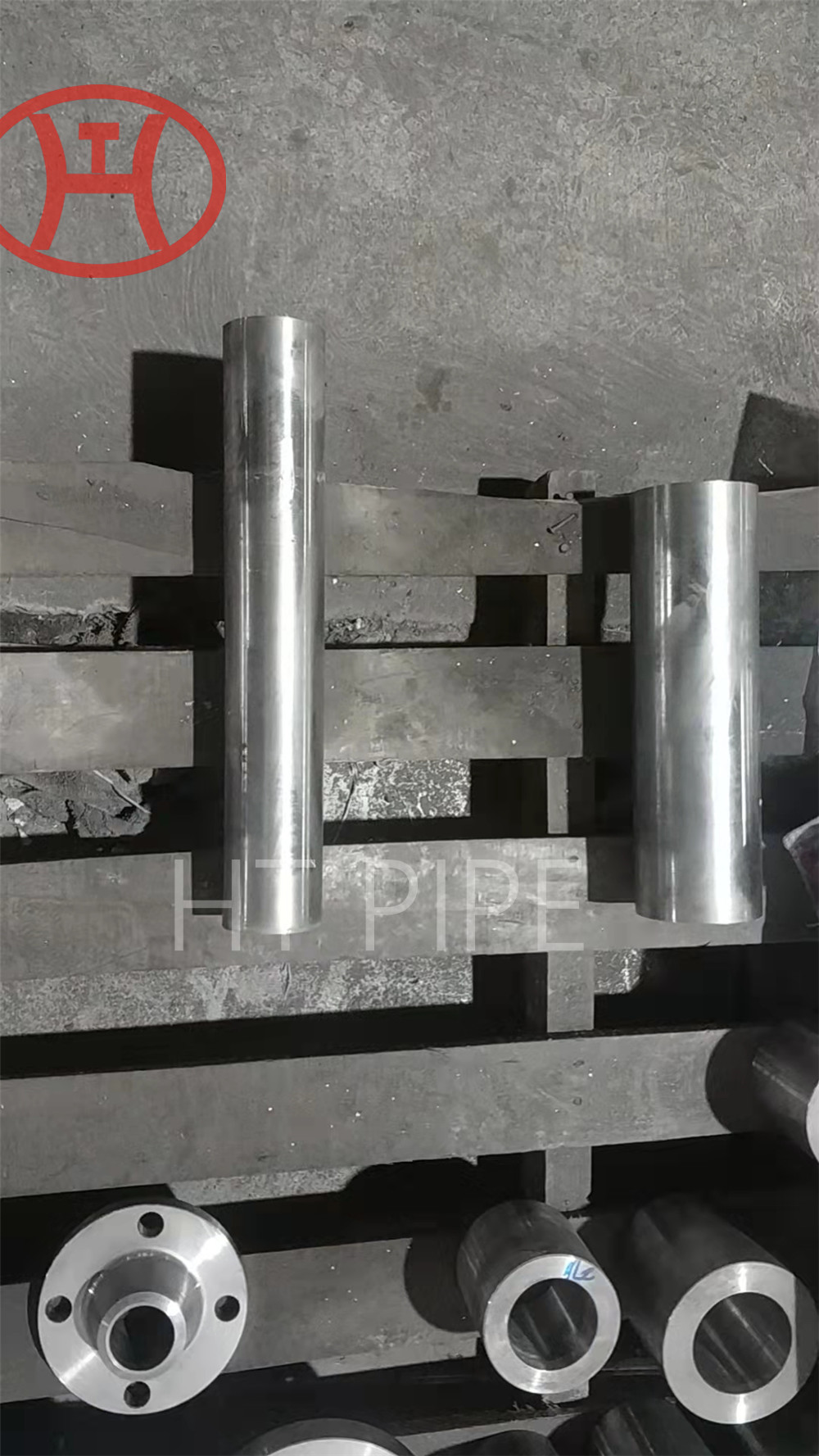

Hastelloy B2 pipe bend nickel molybdenum alloy pipe fittings in inert and vacuum atmospheres

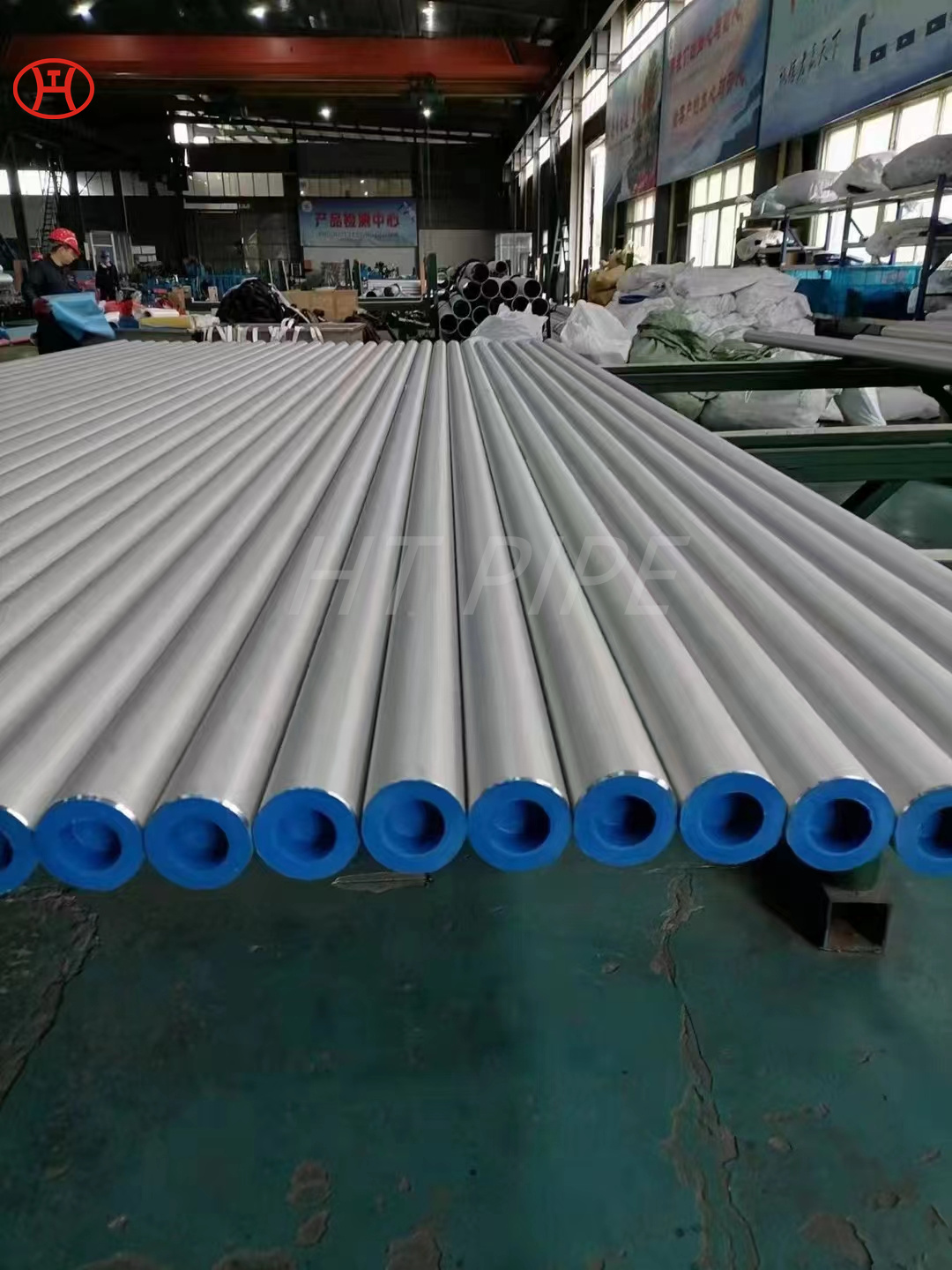

These alloys can function at very high temperatures and in severe mechanical stress environments, and also where high surface stability is required. They have high creep and oxidation resistance.

The high molybdenum content in alloy B-2 pipe bend gives this alloy excellent resistance to hydrochloric acid over a wide range of concentrations and temperatures. Alloy B-2 pipe bend also shows good resistance to hydrogen chloride, sulfuric acid and phosphoric acids and has excellent resistant to pitting and stress corrosion cracking in the heat affected zone. Poor corrosion resistance to oxidizing environments. B2 fasteners are not recommended for use in oxidizing media or in the presence of ferric or cupric salts. These salts may develop when hydrochloric acid comes in contact with iron and copper, causing premature corrosion failure. Like other nickel alloys (in the mill annealed condition), it is ductile, can be formed and welded, and resists stress corrosion cracking in chloride-bearing solutions. Also, it is able to withstand fluoride-bearing media and concentrated sulfuric acid, both of which result in damage to zirconium alloys.