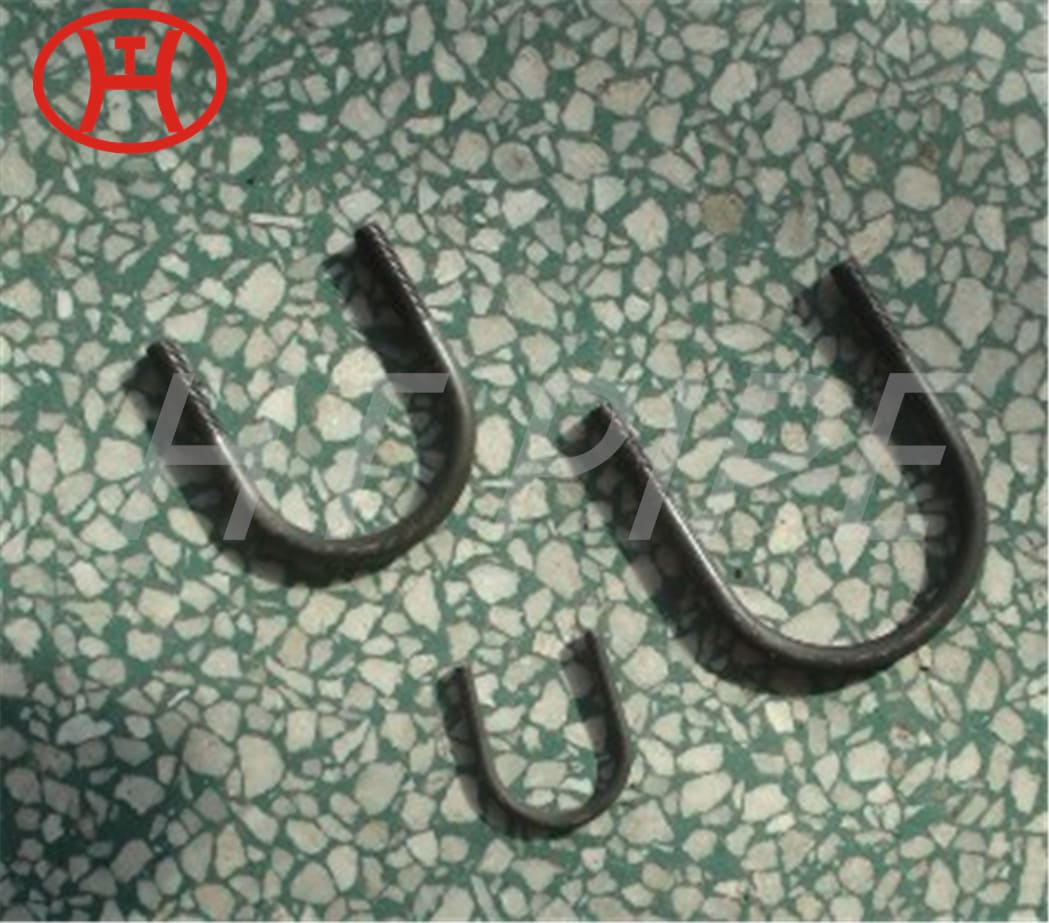

Hastelloy B2 pipe bend offers the excellent resistance to pitting corrosion and stress related corrosion cracking

These salts may develop when hydrochloric acid comes in contact with iron and copper. Therefore, if this alloy is used in conjunction with iron or copper piping in a system containing hydrochloric acid, the presence of these salts could cause the alloy to fail prematurely.

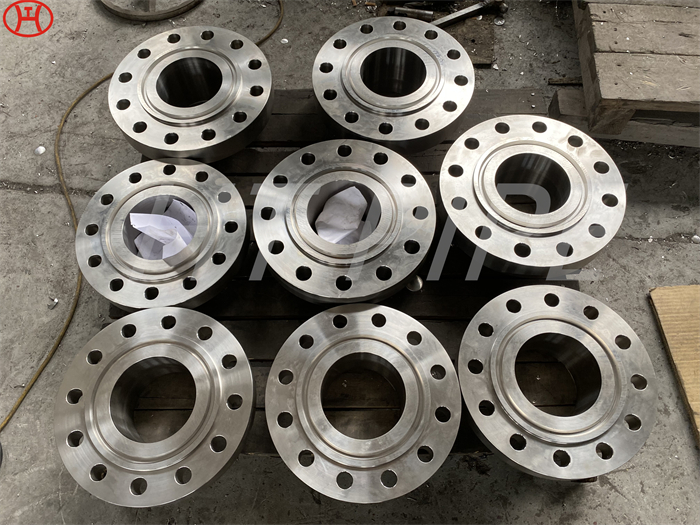

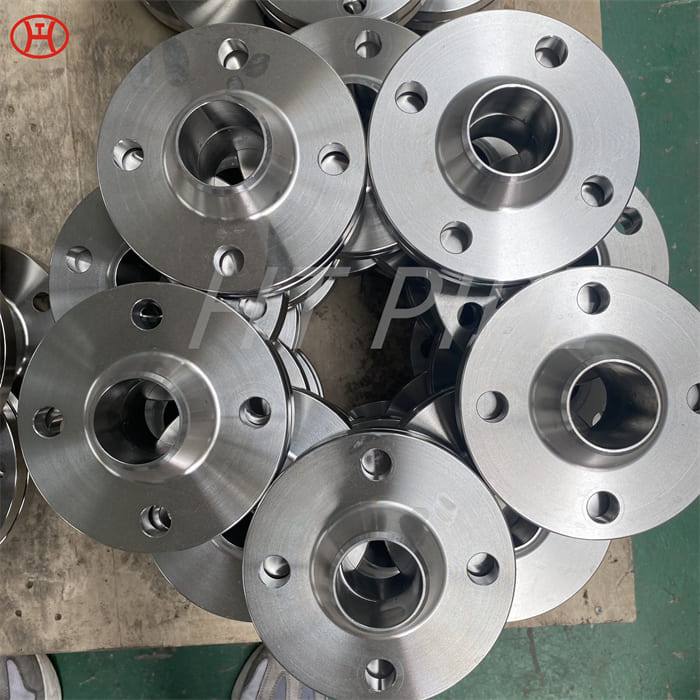

It is easy to weld and can be used as is after welding. The formation of carbide precipitation at the welded joints is less and therefore the heat affected zone is not affected through intergranular corrosion. So the DIN 2.4617 material is resistant to uniform corrosion as well as localized corrosion even after welding. It has very good resistance against stress corrosion cracking and pitting crevice corrosion attack as well. These products are produced following all standards set by various unions with the system. We are the Alloy B2 suppliers who can customize all our products as per your requirements in different shapes and sizes. If you have any queries or want to know more about our products, contact us to know more. Applications in the chemical process industry involving sulfuric, phosphoric, hydrochloric and acetic acid. Temperature uses vary from ambient temperature to 1500¡ãF depending on the environments (please call for technical advice).