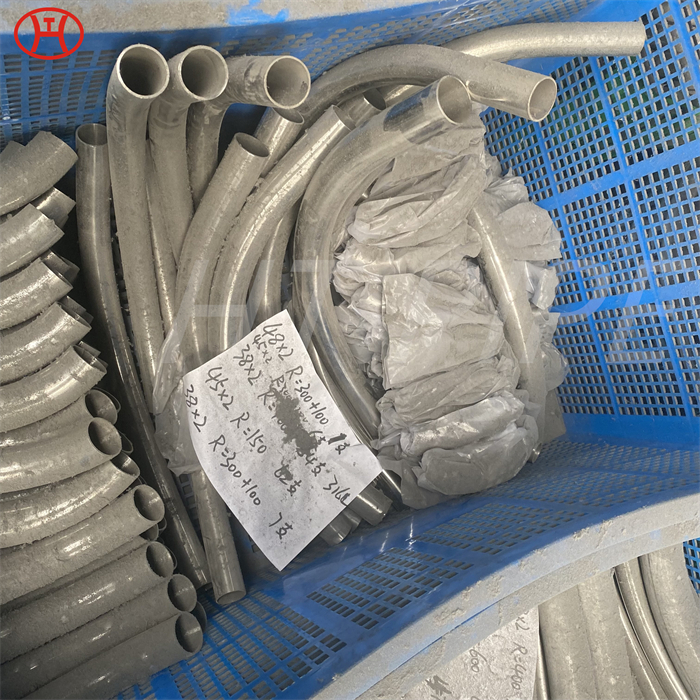

Hastelloy B2 pipe bend with high contents of molybdenum and chromium

Alloy B2 also has excellent resistance to pitting and stress corrosion cracking.

Hastelloy B2 pipe bends are also available in variable types, forms, shapes, grades, length, diameter, etc. the manufacturing of these pipes are usually done according to industrial/national/ international standards. Thus, customers accept to use it in their industries. The alloy work hardens rapidly. Machines should be rigid and powerful, and the tool and workpiece should be held rigid. Tools should be maintained sharp at all times. This alloy may be welded by the gas-metal-arc, gas-tungsten-arc and shielded-metal-arc processes. Parts may normally be used in the as-welded condition, but a post-weld anneal will result in optimum corrosion resistance. Hastelloy is well recognized for its ultimate strength so as to provide extra hardening and finish surface hardening process is done. The improved corrosion resistance is the important feature that last longs at corrosive media. Even these are protected with SATIN and bright black polish that avoids the reduction or rusting in untreated parts.