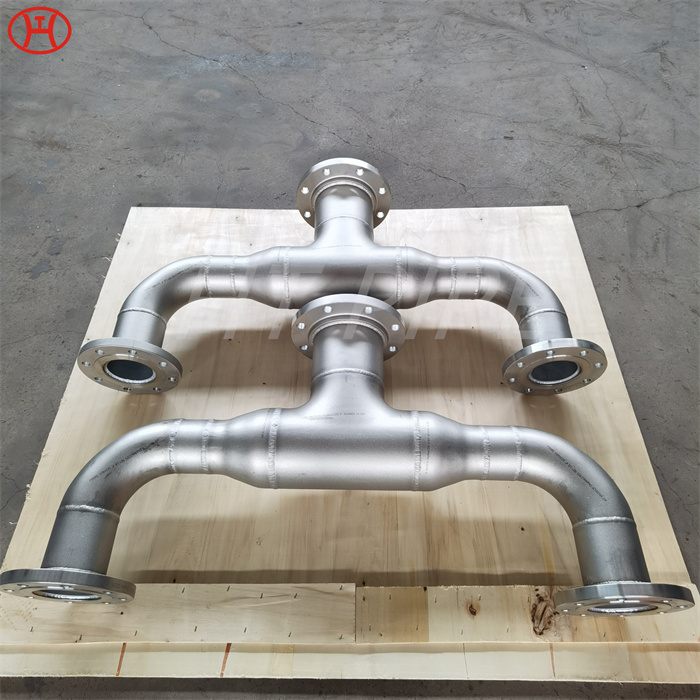

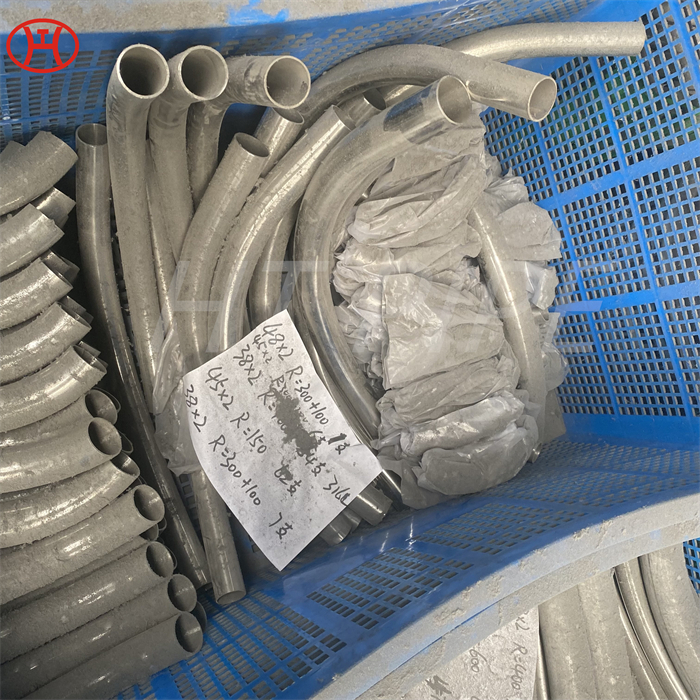

Hastelloy B3 N10675 pipe bend ANSI ASME B16.49 pipe fittings

As the most pipe bending methods are quite cost-efficient, using bent pipes and tubes will have a minimal impact on the overall design budget when using the ideal length and sizing for your application.

As the pipe is pushed through the machine, a Hastelloy B3 bend with the desired radius of curvature is produced. The heated material just beyond the induction coil is quenched with a water spray on the outside surface of the pipe. Thermal expansion of the narrow heated section of pipe is restrained due to the unheated pipe on either side, which causes diameter shrinkage upon cooling. It signifies that there is a ¡°bend¡± i.e, a change in direction of the piping (usually for some specific reason) ¨C but it lacks specific, engineering definition as to direction and degree. Bends are usually made by using a bending machine (hot bending and cold bending) on-site and suited for a specific need. The use of Hastelloy B3 bends is economic as it reduces the number of expensive fittings.