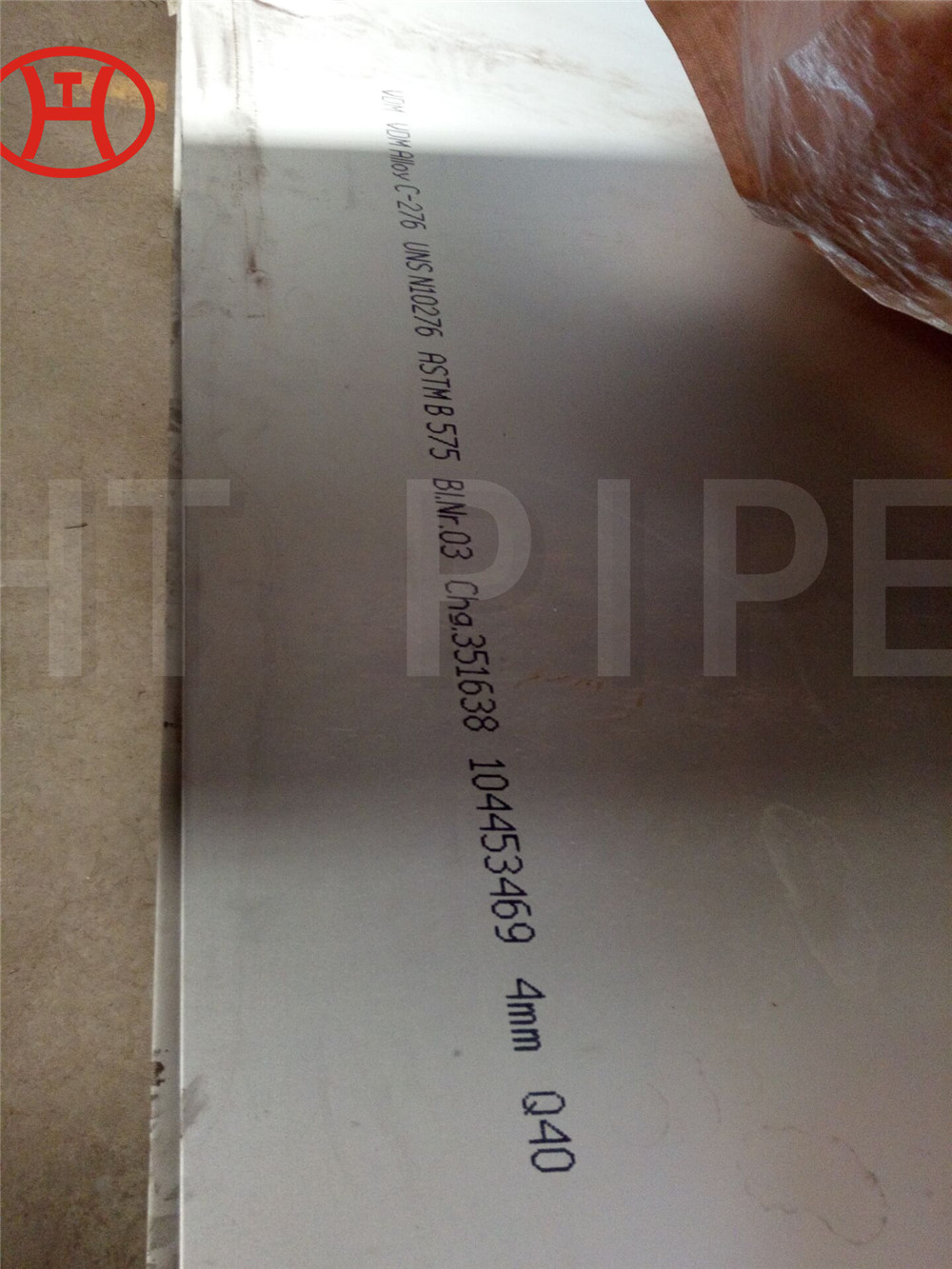

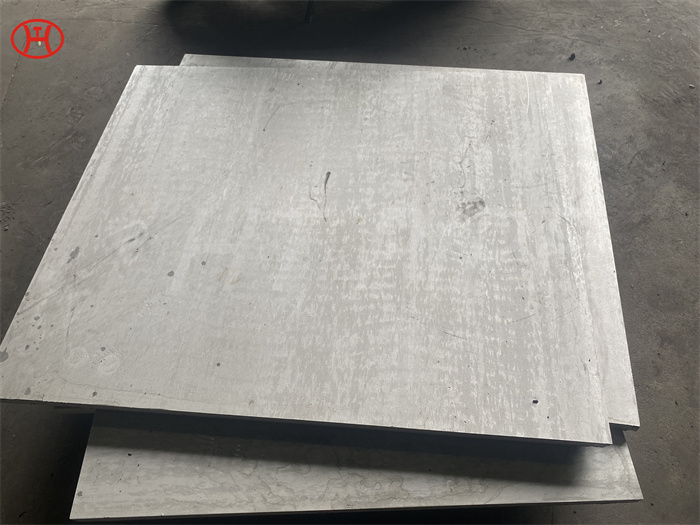

Steel Plate are often used for structural and construction applications, pressure vessels, marine and offshord equipment, and military applications. The grade, elements and parameters of a steel plate are also important in how it is used.

Steel plates are classified by thickness: thin plate, medium plate, thick plate and extra-thick plate.

Thin steel plates are steel plates with a thickness between 0.2-4mm produced by hot rolling or cold rolling, and thick steel plates are those with a thickness of more than 4mm

The general name of the good board.

Thin steel plate refers to a steel plate with a thickness of not more than 3 mm. The commonly used thin steel plate thickness is 0.5-2MM, which is divided into sheet and coil supply. Thin

The steel plates are generally B-type steels, cold-rolled or hot-rolled steel plates with steel grades B0-B3. Requirements for thin steel plates: smooth, smooth surface, thick

The degree of uniformity, allowing a tight iron oxide film, must not have cracks, scarring and other defects. The process is divided into hot rolled sheet steel and cold rolled sheet

plate. Mainly used in Changlin Dongfeng fans, automobiles, electrical equipment, vehicles, agricultural machinery, containers, steel furniture, etc.

Thick steel plates refer to steel plates with a thickness greater than millimeters. Thick steel plate is divided into extra-thick steel plate and medium-thick steel plate.

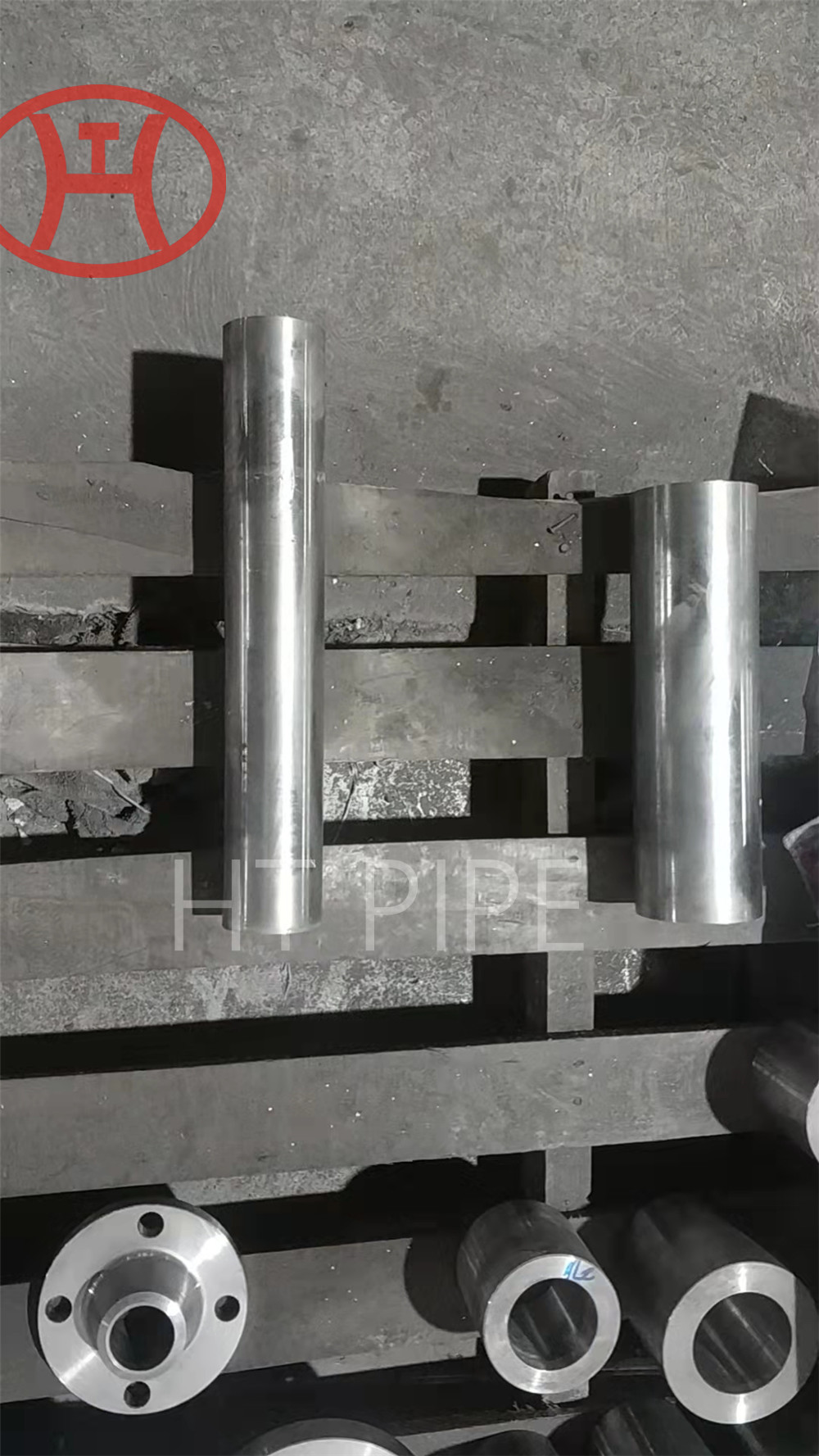

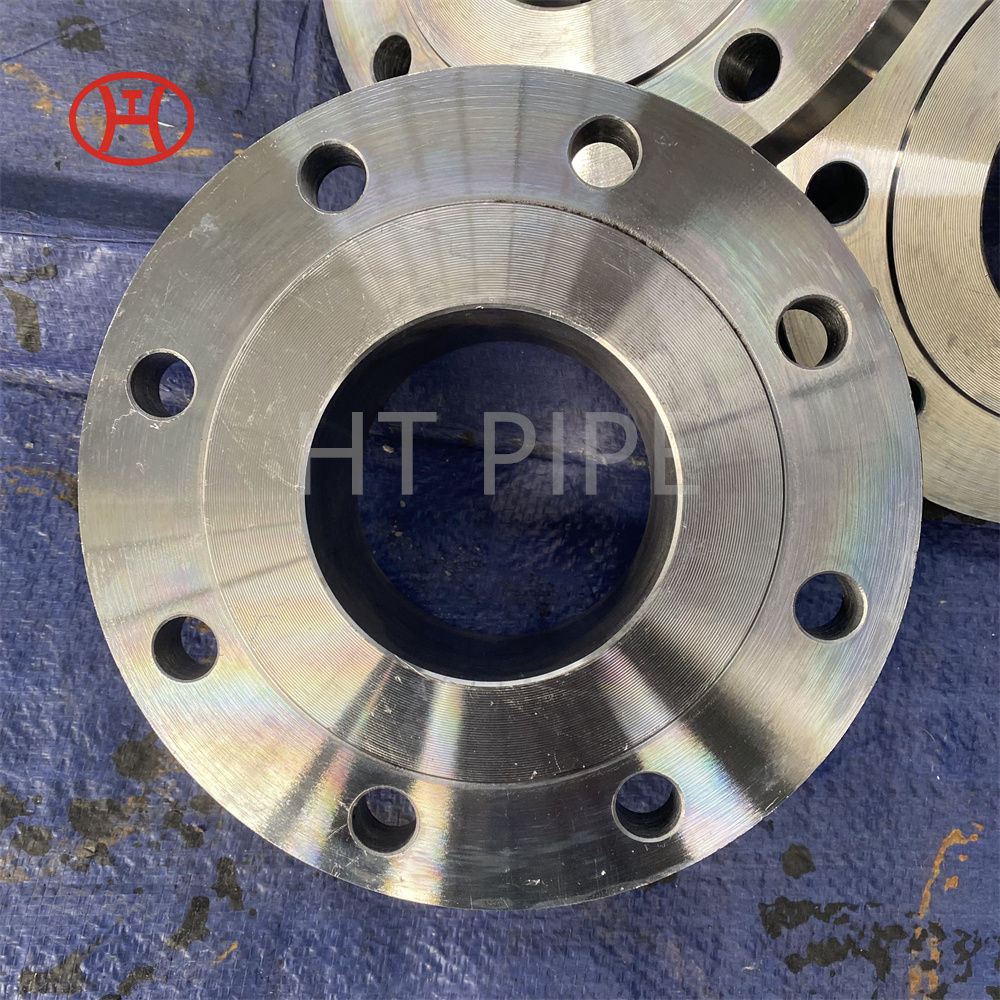

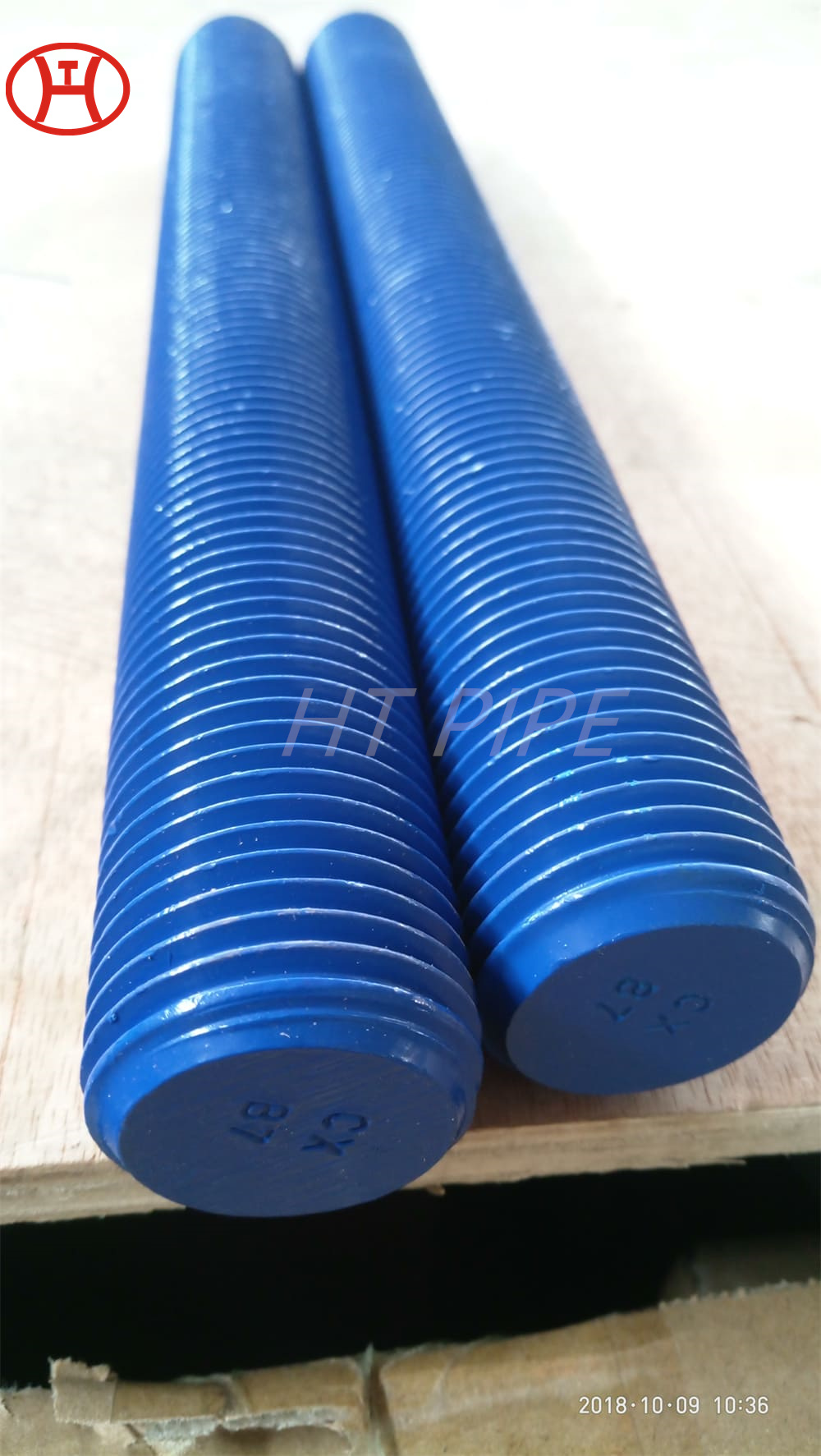

Medium and heavy steel plates refer to steel plates with a thickness greater than 3 mm and less than 50 mm. Medium and thick steel plates are mainly used in shipbuilding, boilers, bridges

Armor and high-pressure vessel shells, etc.

Extra-thick steel plate refers to a steel plate with a thickness of not less than 50 mm. Extra-thick steel plates are mainly used in shipbuilding, boilers, bridges and high-pressure vessel shells

blog.