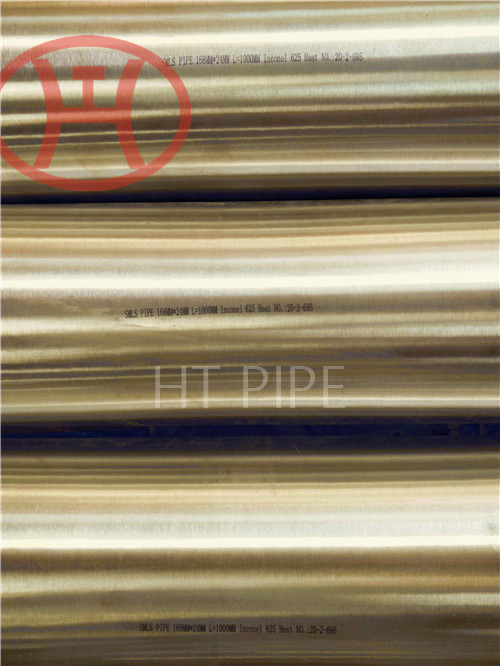

Hastelloy B3 pipe and tube superior to that of its predecessors

This alloy is exhibiting good corrosion resistance at aggressive reducing media like hydrochloric acid that range of concentrations and temperatures and in medium-concentrated sulphuric acid and with limited chloride contamination.

The hastelloy b2 pipe suppliers in Mumbai recommend using this ASTM B622 specified B2 Hastelloy Pipe because the alloy has good resistance to chloride ion induced stress related corrosion cracking or SCC. Austenitic chromium ¨C nickel stainless steels such as these Hastelloy B3 Rectangular Pipes sometimes fail catastrophically by stress ¨C corrosion cracking. This type of failure in Hastelloy B3 Electropolish Pipes is generally associated with an environment containing chlorides as well as with stress, water, dissolved oxygen, and other factors. Alloy B3 is in the group of supperalloys that are called the Hastelloy which are made up of nickel, chromium and molybdenum. There are other elements to increase the mechanical properties of the alloy.