Hastelloy B3 pipe and tube with excellent toughness at cryogenic temperatures

Alloy B-3 also withstands sulfuric, acetic, formic and phosphoric acids, and other non-oxidizing media.

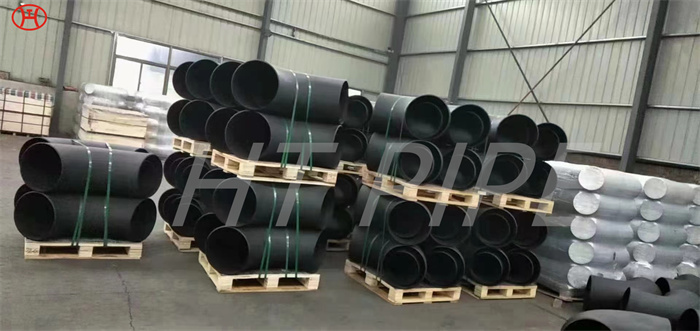

Alloy B-3 or UNS N10675 are manufactured such as ERW ( Electric Resistance Welded), Seamless and EFW ( Electric Fusion Welding) Pipes and Tubes having a different form such as round, square, rectangle, etc having a specific end as Plain End, Bevel End and Threaded End with a nominal thickness of different schedule ranging from SCH 5 to SCH XXS. UNS Number N010675 ERW piping¡¯s distinguishing feature is its ability to maintain excellent ductility during transient exposures to intermediate temperatures. Such exposures are routinely experienced during heat treatments associated with fabrication. The process through which pipes and tubes can be manufactured includes the cold pilfering process, Extrusion process, tube mill Process also Piercing process followed by heat treatment and mechanical testing.