Hastelloy C2000 Pipes ASME SB626 Hastelloy C2000 Welded Tubing

Hastelloy C2000 is available in a variety of sizes and thicknesses, this type of nickel-chromium-molybdenum alloy is renowned for its superior strength and corrosion resistance.

Hastelloy C2000 Pipes, Hastelloy C2000 Tubes, ASME SB626 Hastelloy C2000 Welded Tubing, Hastelloy C2000 EFW Pipe Exporters, ASME SB622 Nickel Alloy C2000 Seamless Cold Finished Tubes Manufactures

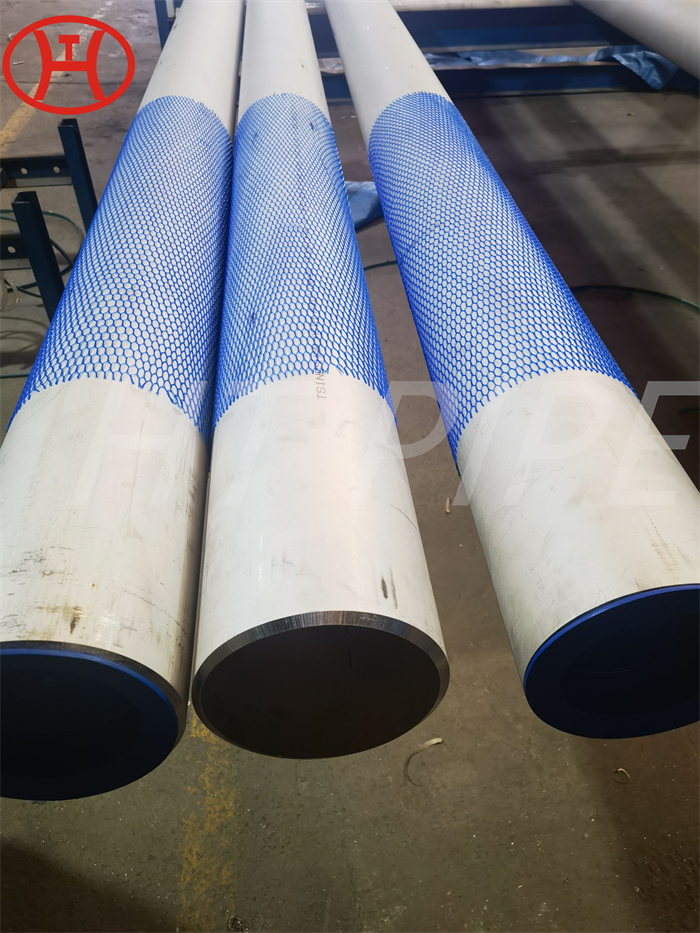

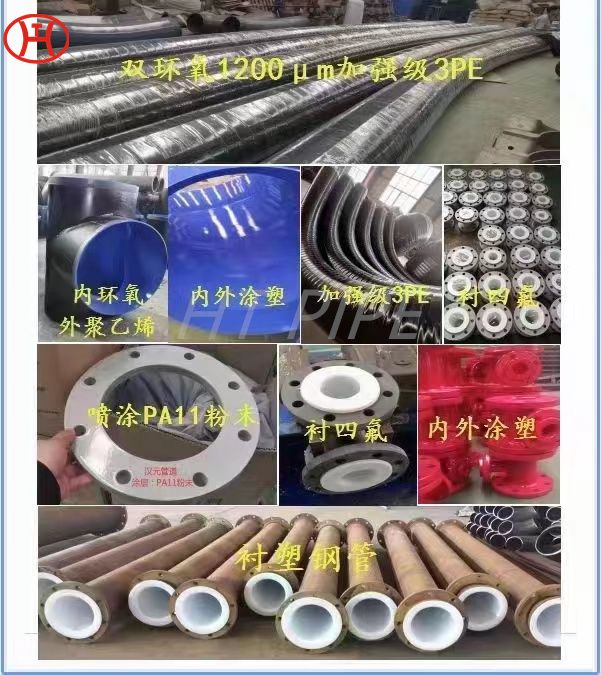

Hastelloy C2000 Pipes can be classified into two main categories: seamless and welded. Hastelloy C2000 seamless pipes are manufactured by cold drawing whereas welded pipes are produced by welding hot rolled coils or plates. Hastelloy C2000 Tubes are used in a broad range of industries including petrochemical processing, chemical processing equipment manufacturing, oil refineries and power plants.

This type of pipe is perfect for applications that require resistance to general corrosion, stress corrosion cracking (SCC), pitting and crevice corrosion as well as oxidation resistance up to 2000°F (1093°C). Hastelloy C2000 ERW Tubes are commonly used in heat exchangers, condensers and evaporators because ASME SB626 Hastelloy C2000 Welded Tubing performs better than many other alloys when exposed to seawater or water containing chlorine ions. Hastelloy B3 Pipes, Hastelloy C22 Tubes and many more grades are also available.

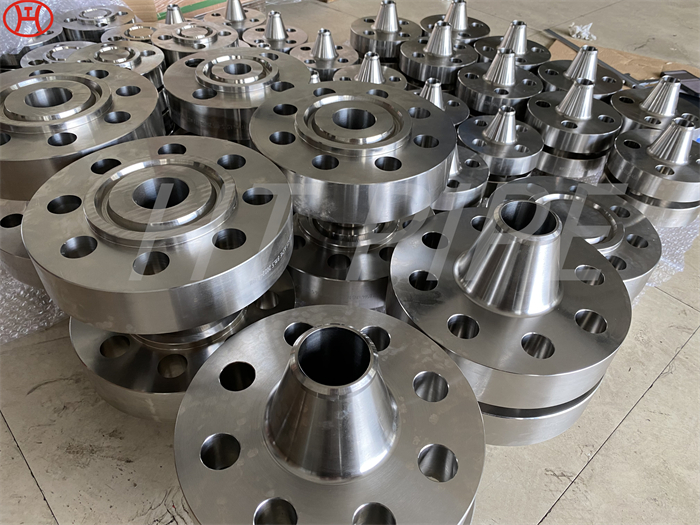

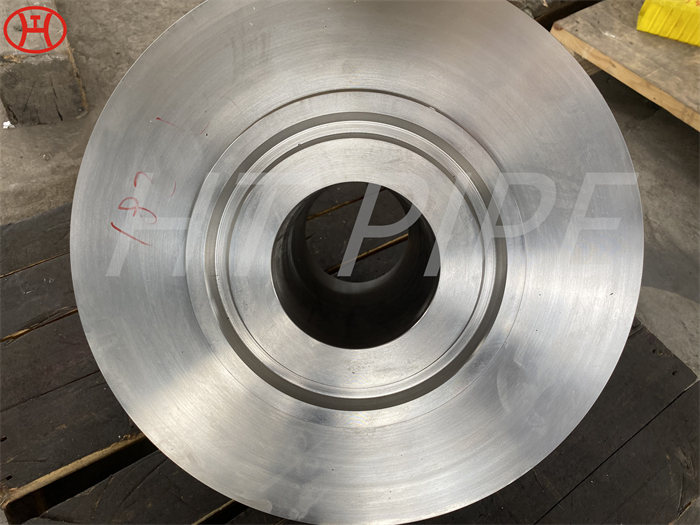

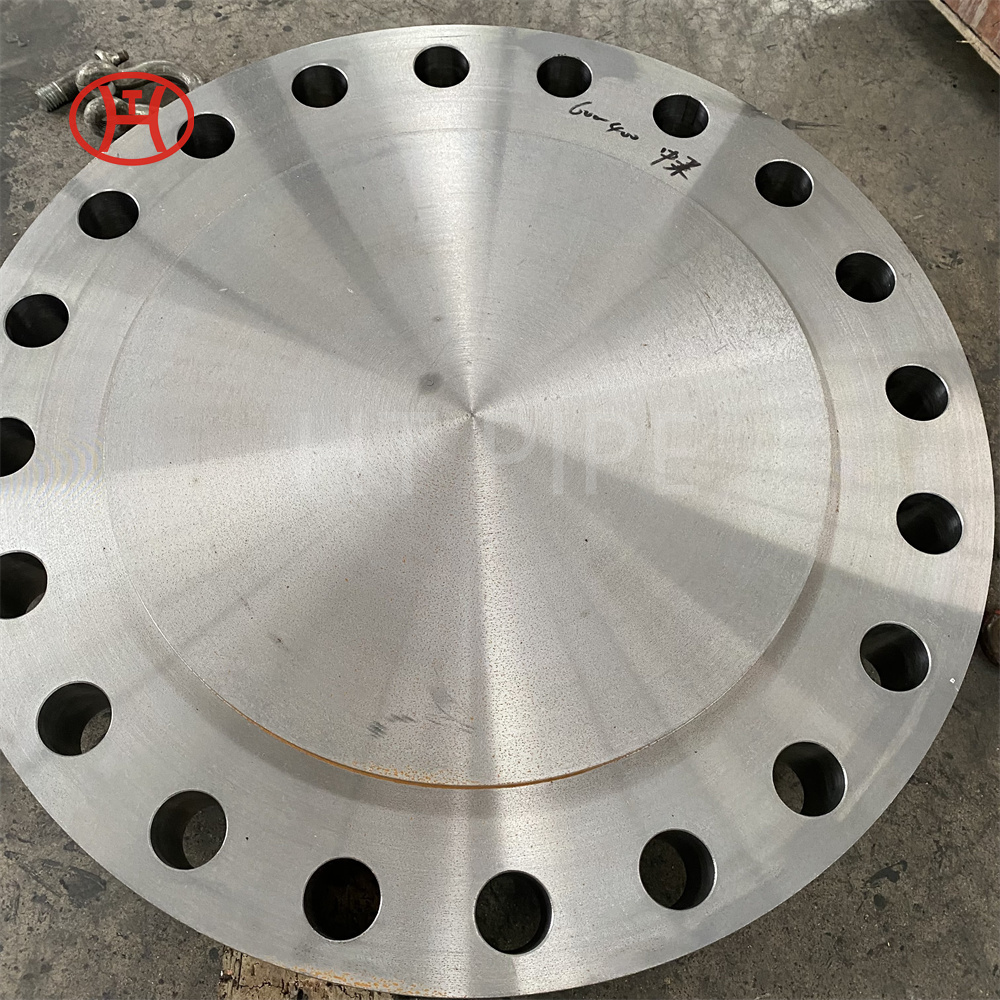

When compared with other alloys like stainless steel or copper nickel, Hastelloy UNS N06200 Pipes offers superior strength at high temperatures along with superior corrosion resistance. This makes Hastelloy C2000 EFW Pipe an ideal choice for use in power plant applications where temperatures exceed 1000°F (538°C). Hastelloy C2000 Seamless Pipes excellent weldability also makes ASME SB622 Nickel Alloy C2000 Seamless Cold Finished Tube easy to assemble components like bends, elbows or tees as well as flanges or fittings; this reduces installation time while providing superior results.

JIS NW 6200 Hastelloy Pipes and Tubes Equivalent Standard

| STANDARD | UNS | WNR. |

| Hastelloy C2000 | N06200 | 2.4675 |

ASTM B622 Hastelloy C-2000 Seamless Pipe & Tube Chemical Composition

| Grade | Ni | Mo | Cr | Fe | W | Co | Mn | C | V | P | Si |

| Hastelloy C2000 | Remainder | 15.0-17.0 | 14.5-16.5 | 4.0-7.0 | 3.0-4.5 | 2.5 max | 1.0 max | .01 max | .35 max | .04 max | .08 max |

ASME SB626 Hastelloy C2000 Welded Tubing Mechanical Properties

| Grade | Tensile Strength | Yield Strength | Elongation at break |

| Hastelloy C2000 | 690 MPa | 310 MPa | 45% |