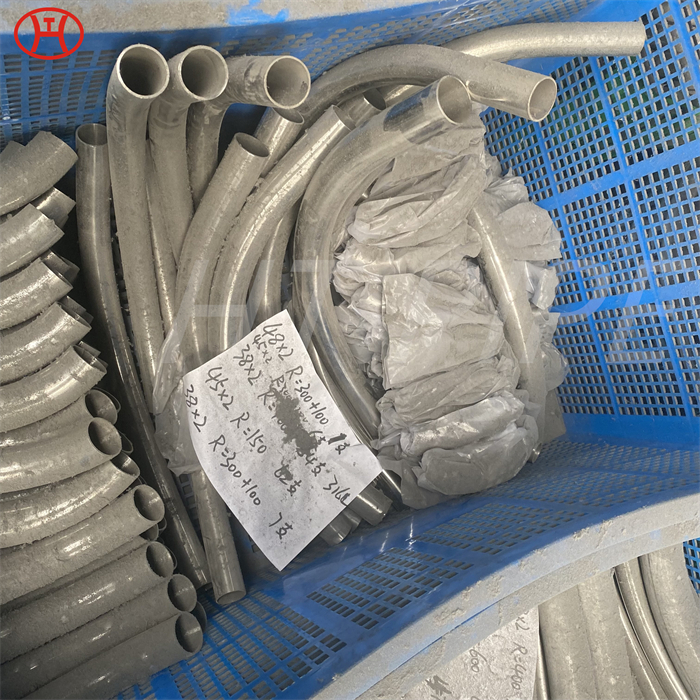

Hastelloy C22 pipe bend be utilized in high-temperature conditions

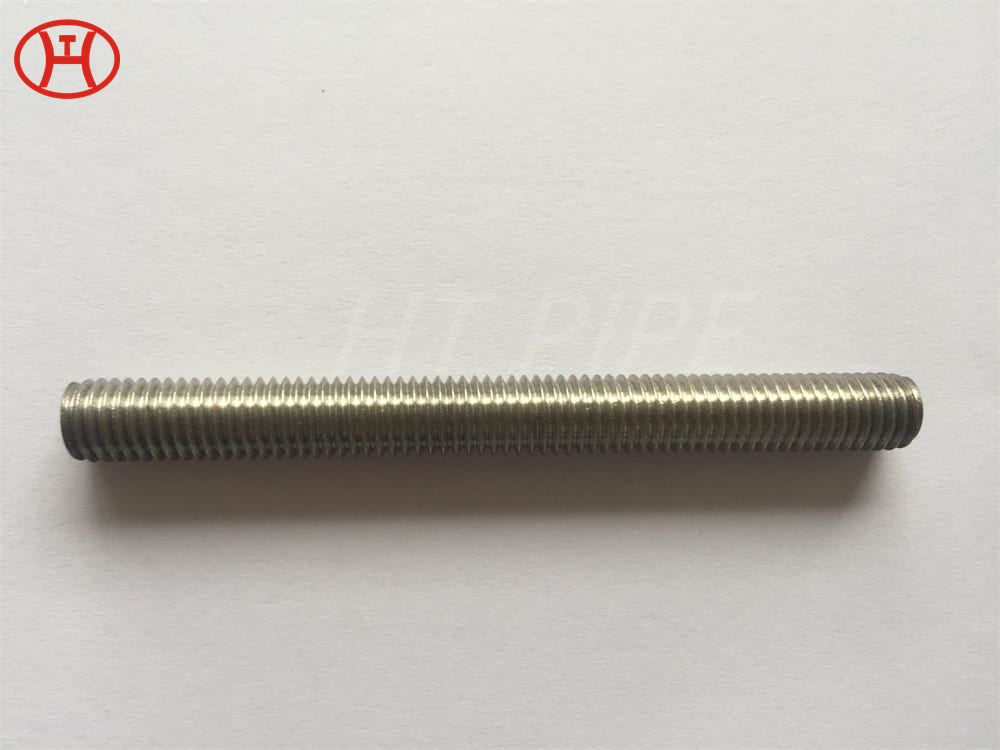

Other corrosives Hastelloy C-22 has resistance to are oxidizing acid chlorides, wet chlorine, formic and acetic acids, ferric and cupric chlorides, sea water, brine and many mixed or contaminated chemical solutions, both organic and inorganic.

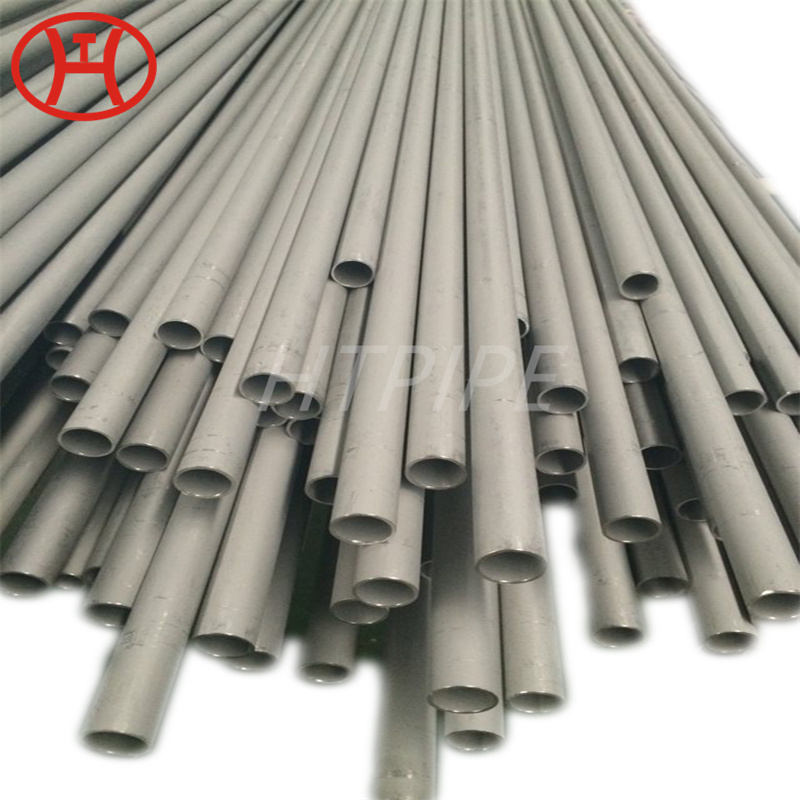

Hastelloy C22 pipe bend contains chromium, molybdenum, tungsten, and iron which makes the alloy resistant to corrosion in stagnant or flowing seawater. The alloy is formed by gas tungsten-arc, gas metal-arc, and shielded metal-arc processes. Hastelloy 22 has found numerous applications in the chemical/petrochemical processing, pollution control (flue gas desulfurization), power, marine, pulp and paper processing, and waste disposal industries. At elevated temperatures, the high chromium level of Hastelloy C-22 Alloy helps it resist oxidation, carburization, and sulfidation. Hastelloy is an alloy of austenitic nickel-chromium and molybdenum alloy. The Hastelloy C22 alloy is designed with superior strength and excellent corrosion resistance properties. These alloys have good wear resistance and can suffice in extreme temperatures and pressures. The Hastelloy C22 material is made with excellent mechanical properties.