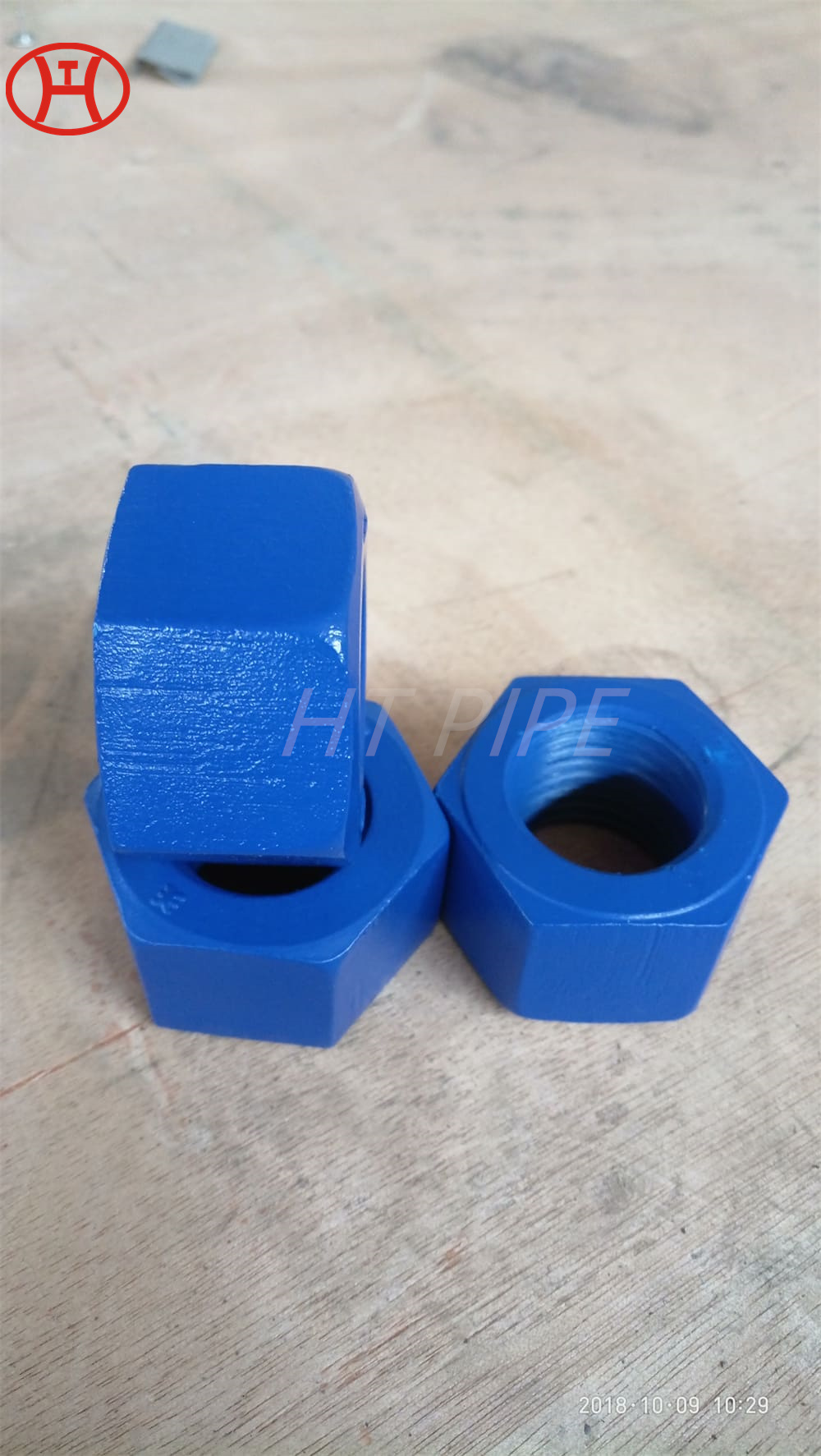

Hastelloy C22 pipe bend Hastelloy C22 Butt weld Fittings

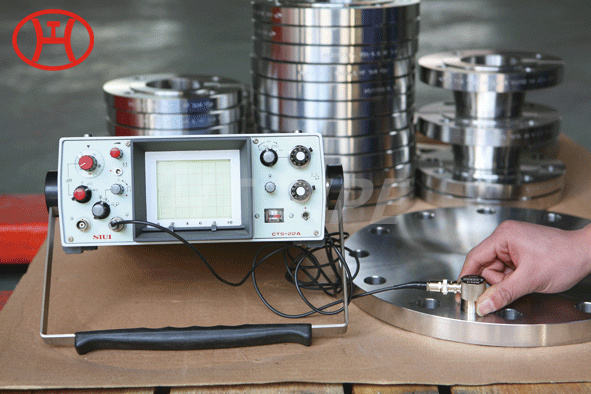

Hastelloy C22, also known as alloy C22, is a versatile austenitic nickel-chromium-molybdenum-tungsten alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking.

C22 can be hot worked or cold worked. However, C22 work-hardens rapidly. Therefore, cold working must often be performed in stages with intervening anneals. Parts should be annealed after cold working. Hastelloy C-22 can be fabricated using the same techniques as are used for alloys C-276 or C-4. It can be welded, forged, hot-upset and impact extruded. Alloy C-22 can also be successfully deep-drawn, spun, press formed or punched, although the alloy tends to work-harden. Parts which have been hot formed or severely cold formed should be heat treated at 2050 ¡ãF and rapid quenched prior to final fabrication or installation. The exceptional corrosion resistance of C22 has promoted its use in many different markets wherever harsh environments are encountered, including the chemical process, pharmaceutical, food processing, oil & gas, power generation, and the paper industries.