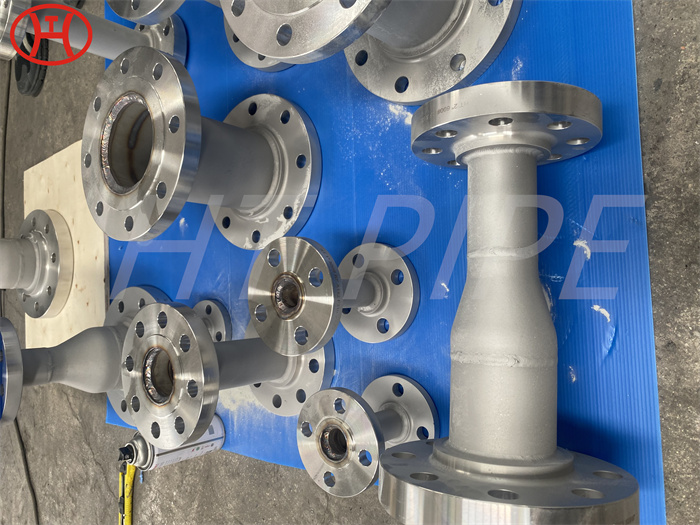

Hastelloy C22 pipe bend Hastelloy C22 Pipe Fittings Manufacturer and supplier in China

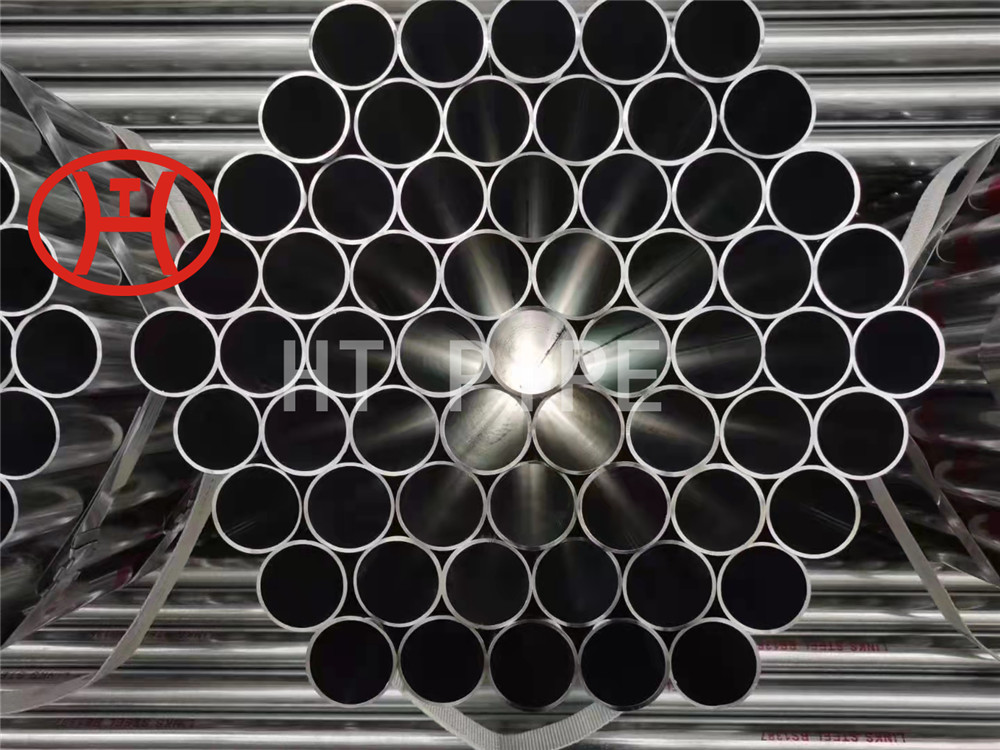

Hastelloy C-22 (UNS N06022) pipe bends and fittings in stock, allowing for a quick turnaround. Hastelloy C-22 has excellent resistance to aggressive oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chlorine ions.

Alloy C22 pipe bend is a nickel-chromium-molybdenum solid solution strengthened super-alloy with a nominal chemical composition of 56% nickel, 22% chromium, and 13% molybdenum, with additions of iron, tungsten, and cobalt. HASTELLOY Alloy C-22 is a nickel-chromium-molybdenum alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking. It resists the formation of grain boundary precipitates in the weld-heat affected zone making it suitable for use in the as-welded condition. Hastelloy C-22 is a most versatile nickel-chromium-molybdenum-tungsten alloy with improved resistance to both uniform and localized corrosion as well to a wide variety of mixed industrial chemicals. Hastelloy C-22 is a versatile nickel-chromium-molybdenum alloy with better overall corrosion resistance than other Ni-Cr-Mo alloys available today, including hastelloy C-276, C-4, and A625. Alloy C-22 pipe bend has outstanding resistance to pitting, crevice corrosion and stress-corrosion cracking.