Hastelloy C22 pipe bend not sensitive to heating and welding processes

Alloy C-22 should not be used in service temperatures above 1250¡ã F due to the formation of detrimental phases which form above this temperature.

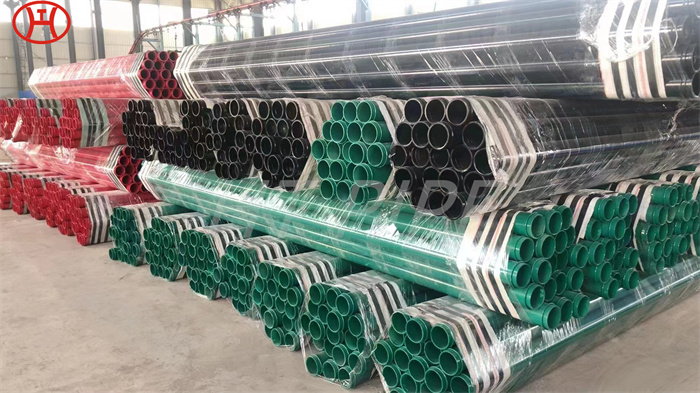

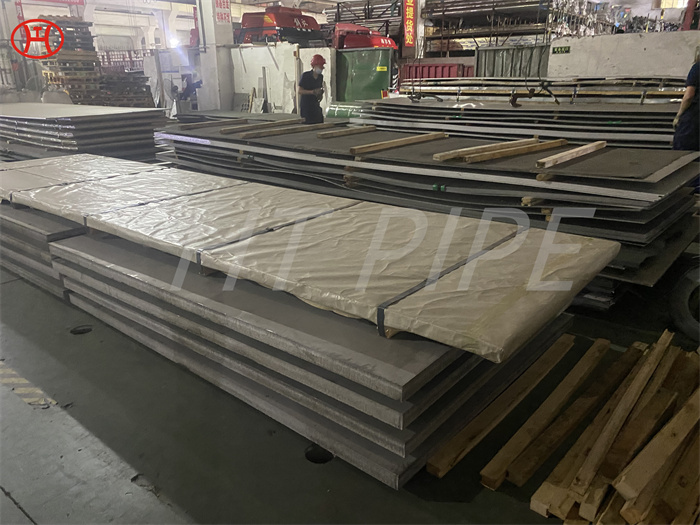

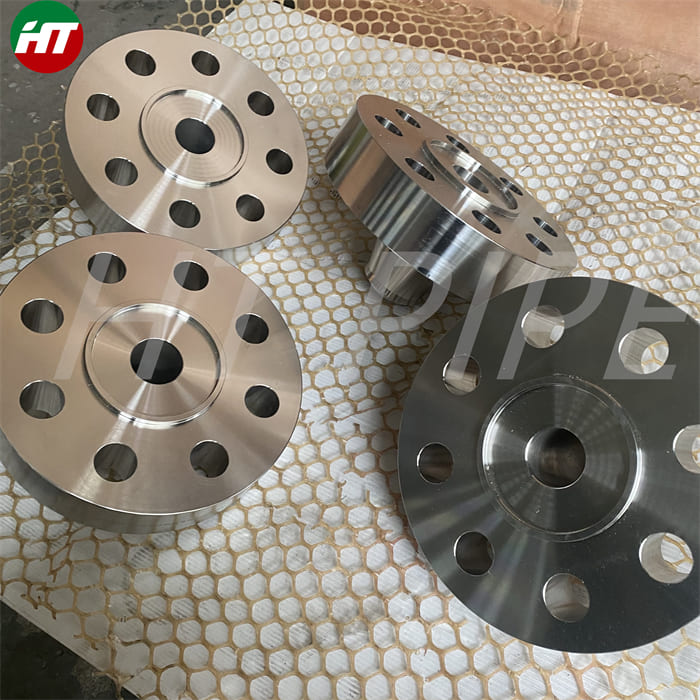

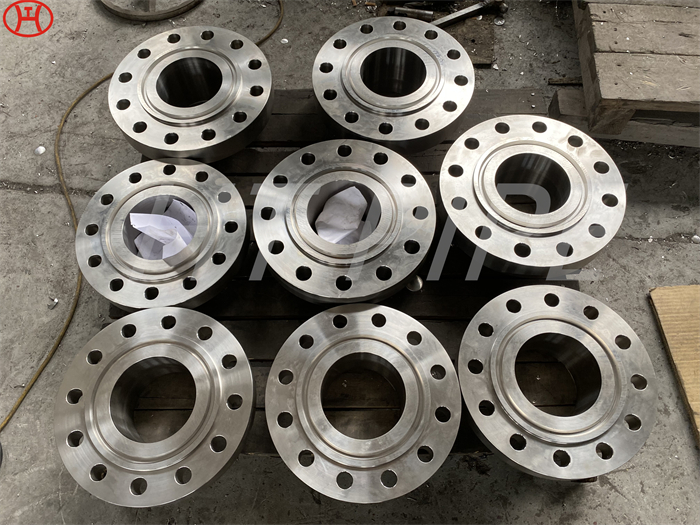

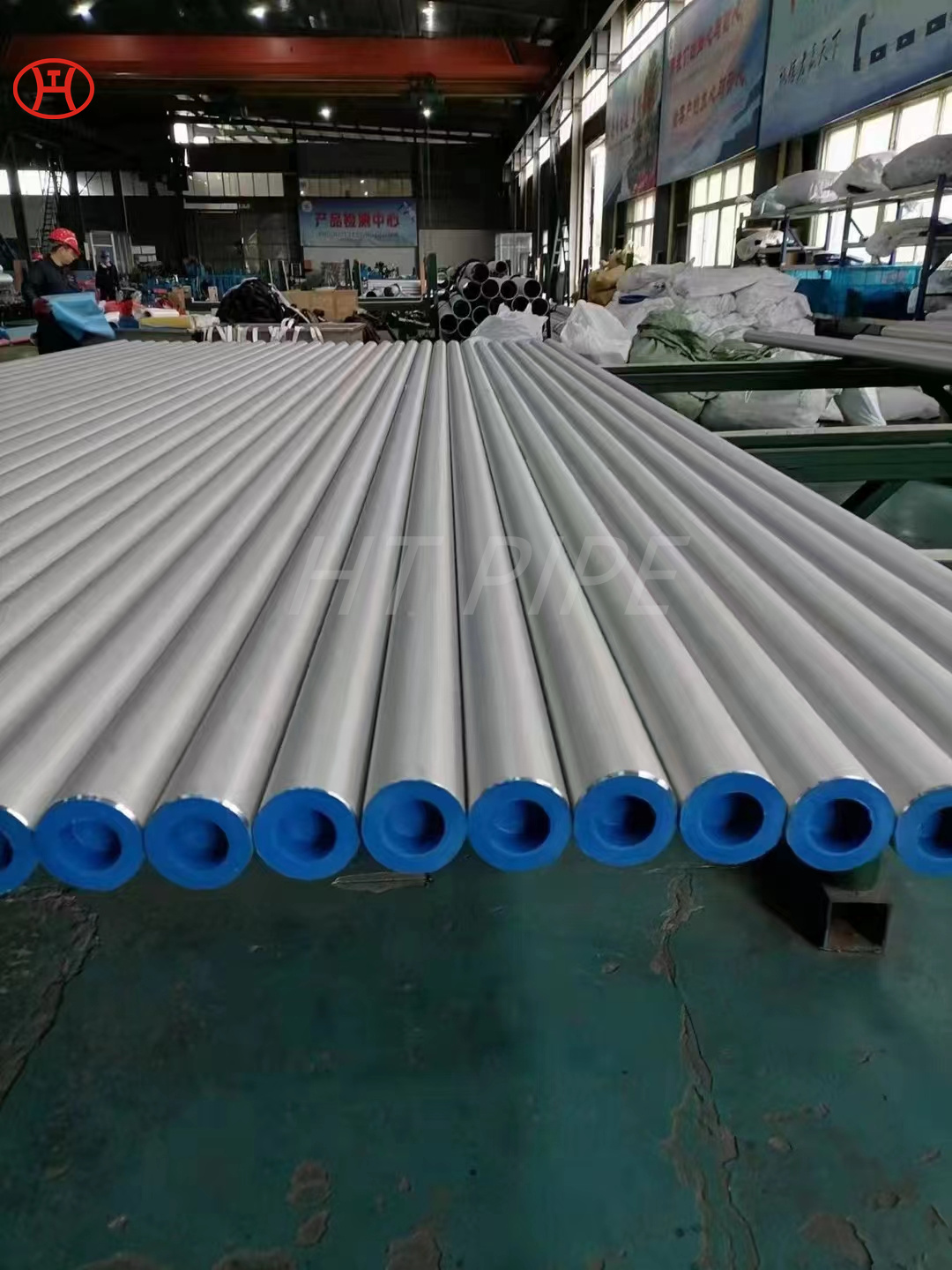

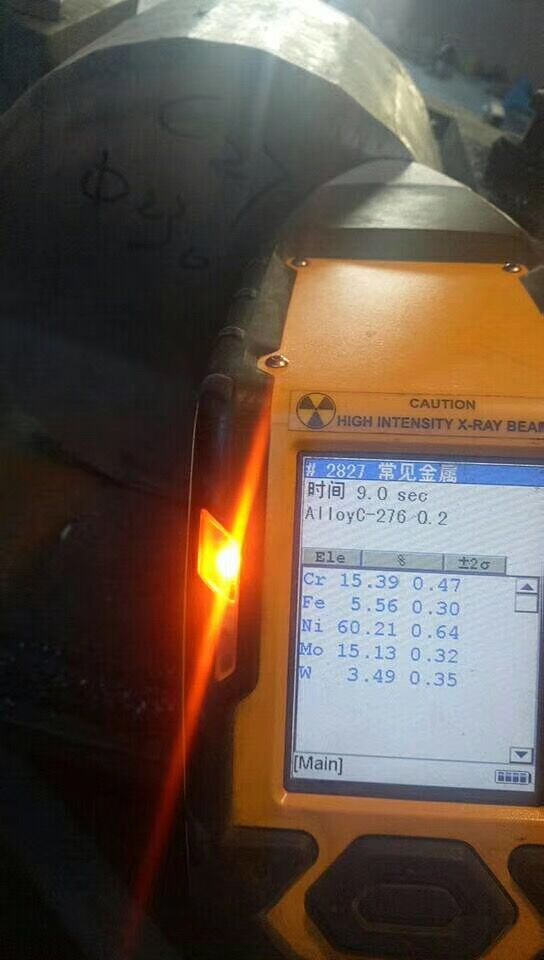

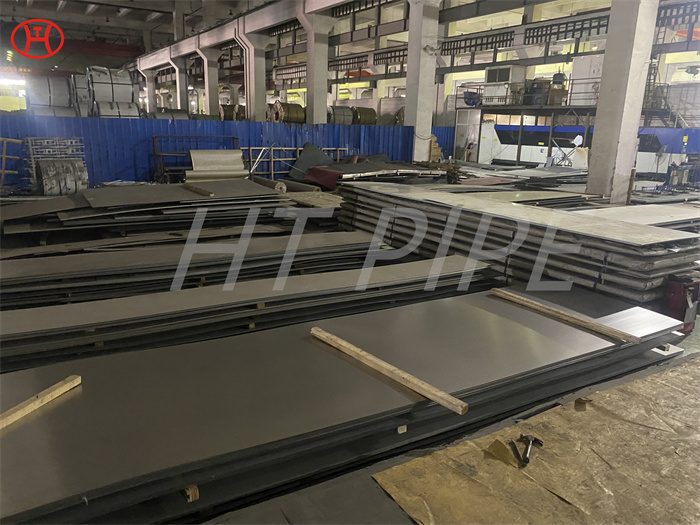

Hastelloy C22 pipe bend has good versatility and resistance to chloride-induced pitting HASTELLOY C-22 alloy (UNS N06022) is a well-known nickel chromium-molybdenum materials, some main attributes are resistance to both oxidizing and non-oxidizing chemicals, protection from pitting, crevice attack, and stress corrosion cracking. C22 has a high chromium content that provides much higher resistance to oxidizing media than C-276 alloy. Like other nickel alloys, HASTELLOY C-22 alloy is quite ductile, exhibits excellent weldability, and is fabricated easily into industrial components. It is available in the form of plates, sheets, strips, billets, bars, wires, pipes, and tubes. Typical applications might include: reactors, heat exchangers, and columns. Alloy C22 is a member of a family of superalloys that are made up of nickel, chromium and molybdenum. There are other elements in the composition as well. But the major elements make the alloy resistant to much reducing environments, oxidizing agents and make it stronger as well.