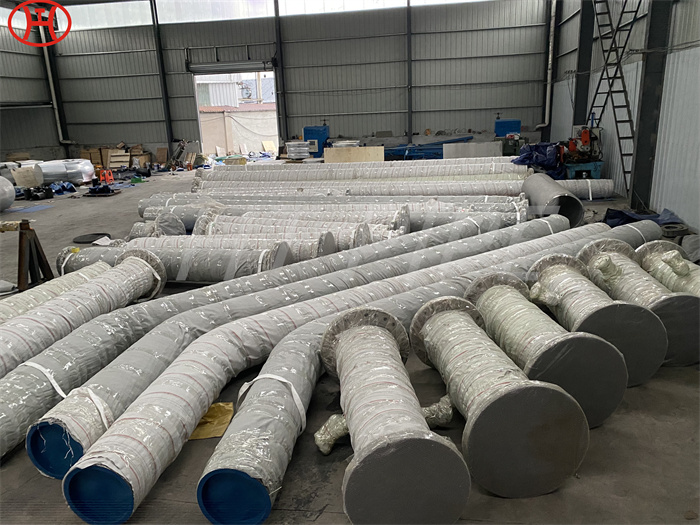

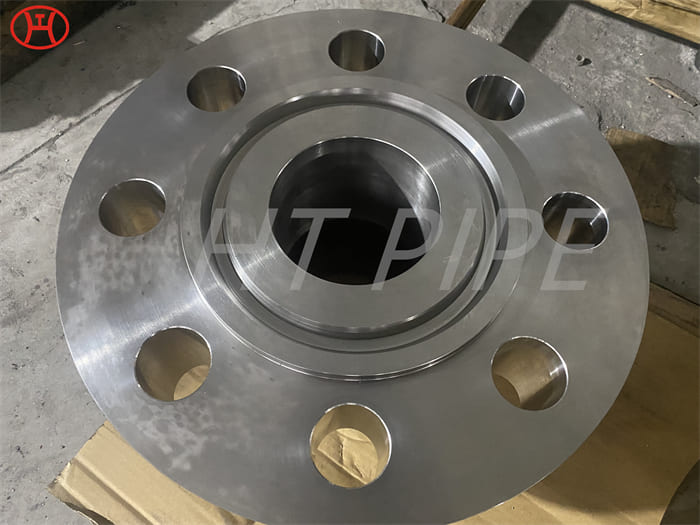

Hastelloy C22 pipe bend quality-assured and available at the most reasonable prices

C22 has excellent resistance to chloride-induced localized corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

At elevated temperatures, the high chromium level of Hastelloy C-22 pipe bend helps it resist oxidation, carburization, and sulfidation. Since it is nickel-base, alloy 22 resists high temperature attack by halides (e.g., chlorides and fluorides). With these attributes, the alloy is widely used to protect steel tubes and other components in coal-fired and waste-to-energy boilers. Alloy 22 is used in the petrochemical and chemical industry. 2.4602 is a common material when it comes to contact with hot, contaminated mineral acids, solutions or seawater. It is used also in bleaching containers (such as in the pulp and paper industry) and acetic acid production in a reactor. Alloy 22 also occurs in components with sour gas applications. The combination of good weldable properties along with resistance to the grain-boundary precipitate being formed on the enables the Hastelloy C22 Tube to be used in an as welded condition. This being said, however, the Tubing Sb 622 UNS N06022 must not be used beyond a temperature of 1250¡ã F. At temperatures exceeding 1250¡ã F, the Hastelloy UNS N06022 Tubing material is prone to the formation of detrimental phases. This, in turn, could lead to loss of several important properties of the ASTM B622 UNS N06022 Tube.