hastelloy c22 tube N06022 2.4602

Hastelloy C-22 can be used in conjunction with Hastelloy C-276 to prevent joint corrosion. Its composition is nickel-chromium-molybdenum-tungsten, giving it some of the resistance that is characteristic of C-276. The metal is excellent against overall and localized corrosion, along with chemical, oxidation, and reducing environments. Tests in environments containing wet chlorine and nitric acid have also proved that Hastelloy C-22 shows exceptional resistance. However, one unique characteristic is its weldability, which allows the metal to be used as a filler in many cases where other metals have failed to stop corrosion. These characteristics make Hastelloy C-22 commonly applied in chemical productions for food and beverages and pharmaceutical tools.

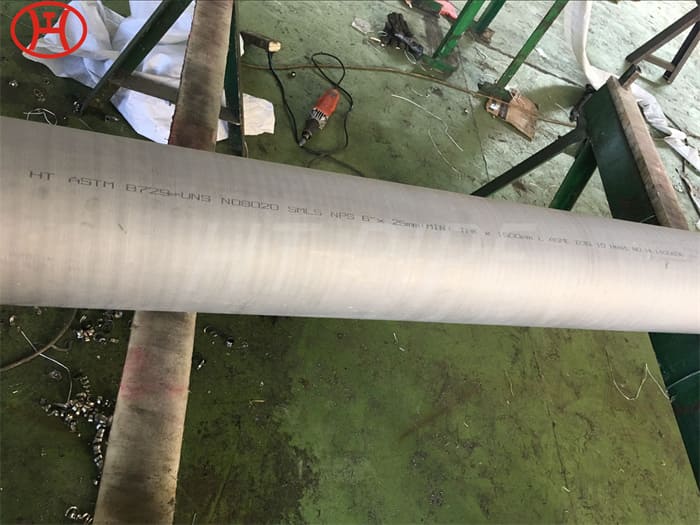

Type Seamless Pipe

Seamless Tube

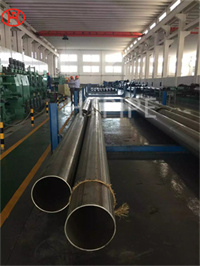

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.19

Material Nickel Alloy ASTM B474 UNS N02200/Ni 200, UNS N02201 /Ni201, UNS N04400/ Monel 400, UNS N06002 /Hastelloy X, UNS N06022/ Hastelloy C22, UNS N08825/ Incoloy 825 ,UNS N10276/ Hastelloy C276, UNS N10665 /Hastelloy B2, UNS N10675/Hastelloy B3, UNS N06600/Inconel 600 ,UNS N06601/ Inconel 601 ,UNS N06625 /Inconel 625 ,UNS N08020 /Alloy 20

ASTM B161 UNS N02200/Ni 200, UNS N02201 /Ni211