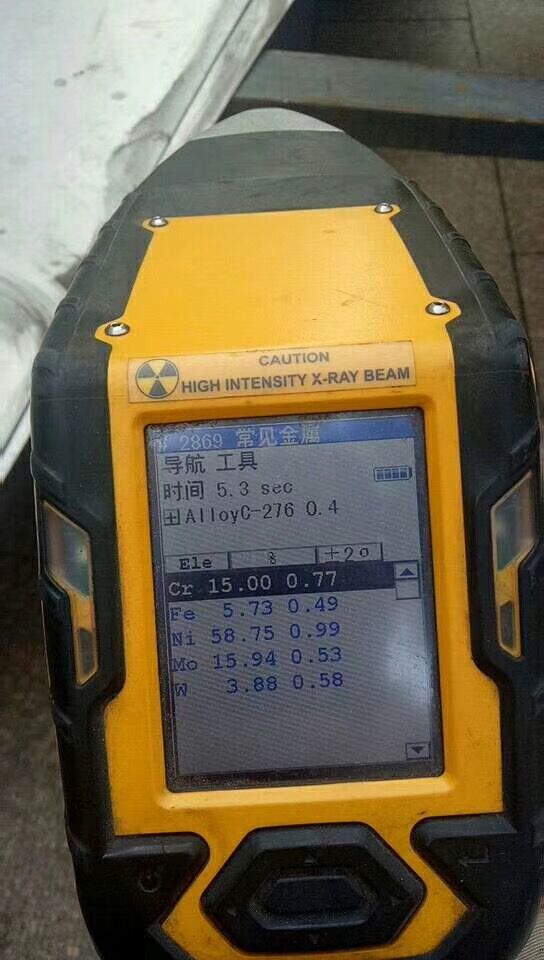

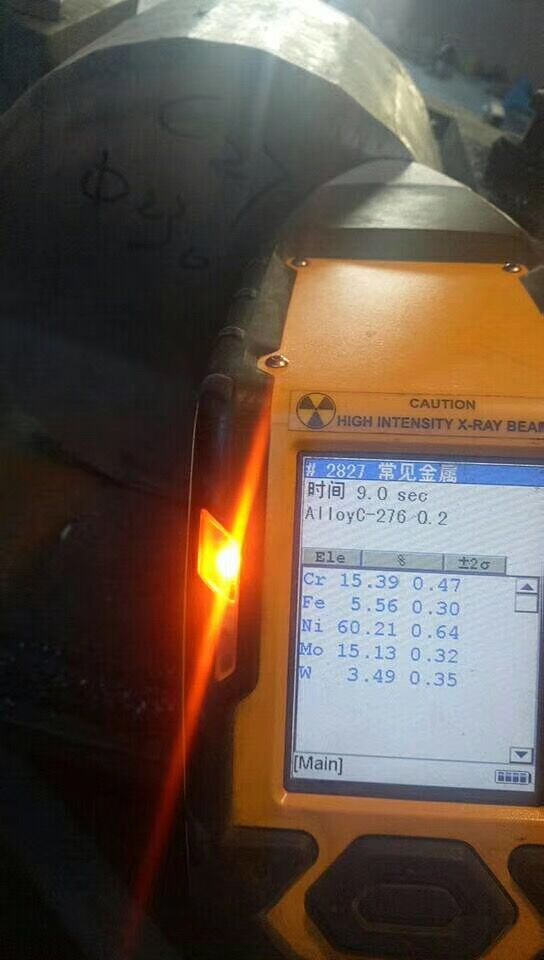

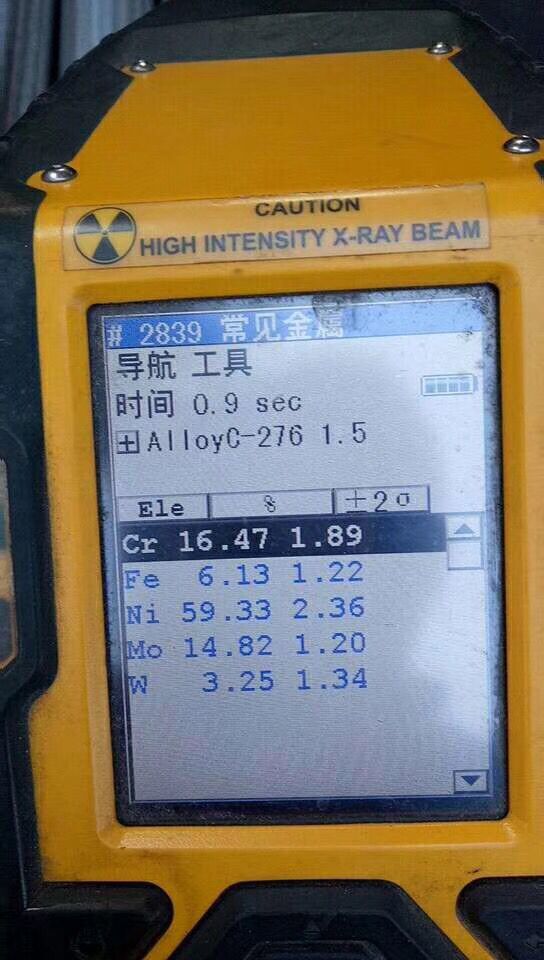

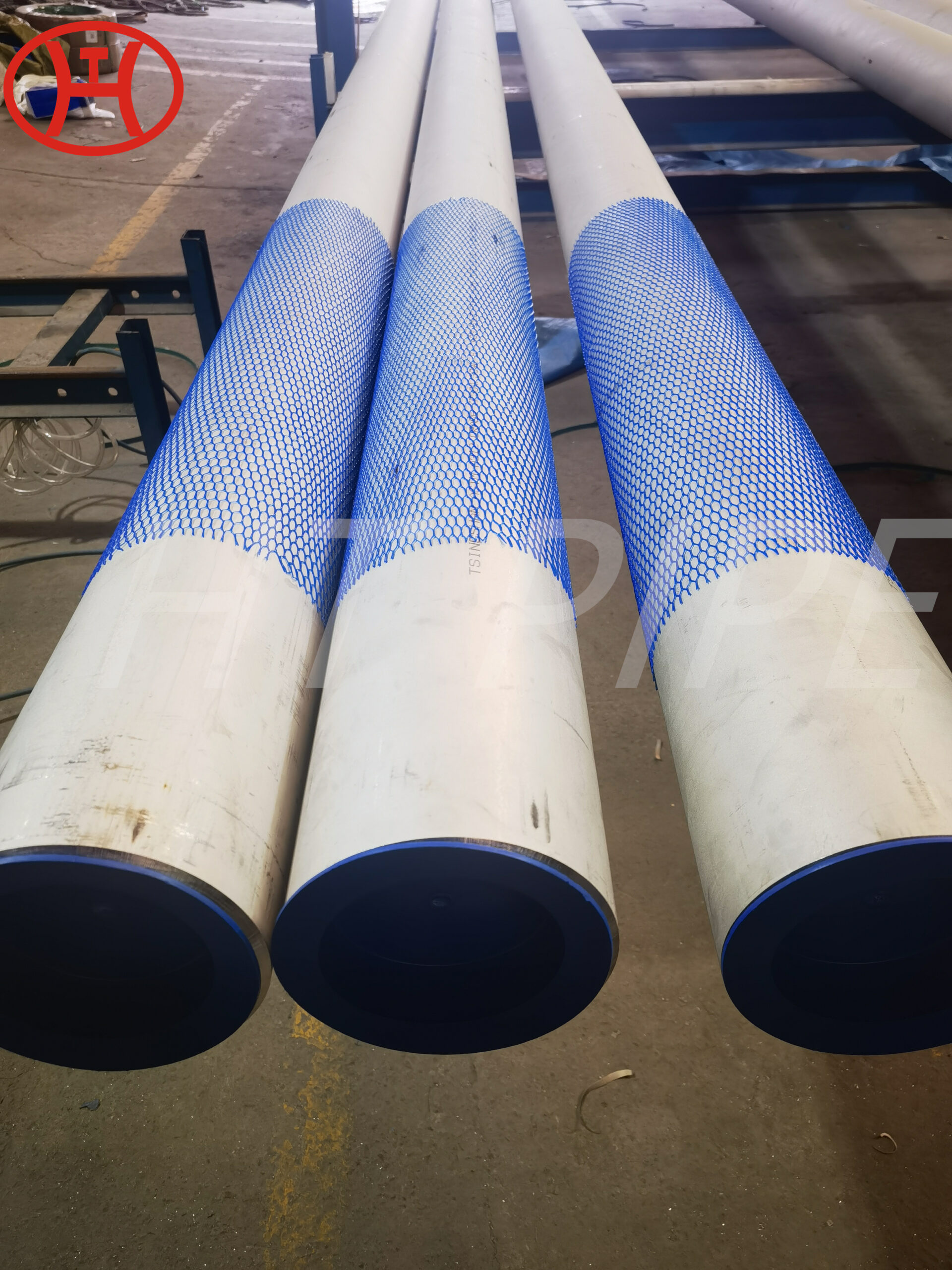

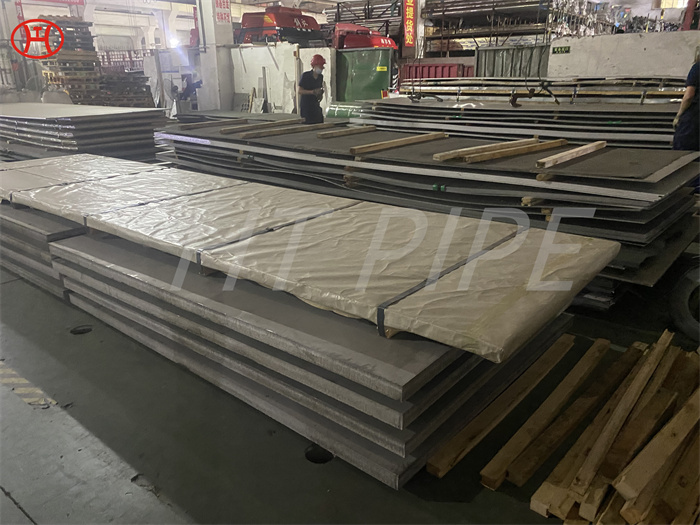

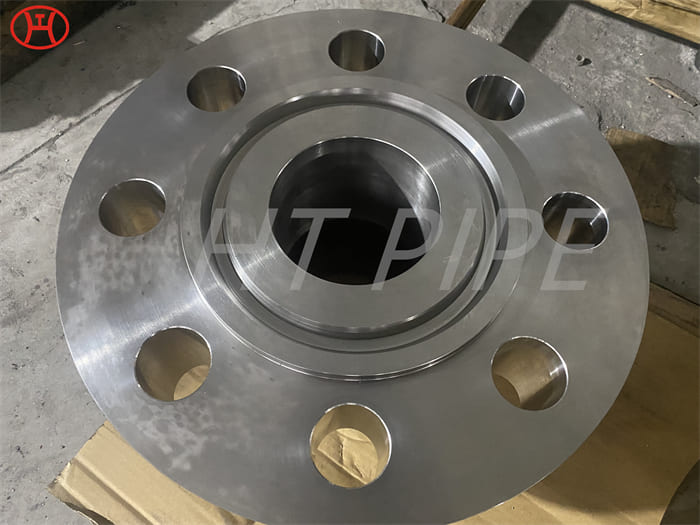

Hastelloy C276 2.4819 N10276 PMI testing C276 steel round bar and plate PMI testing

The Ni-Cr-Mo superalloy Hastelloy C276 has excellent resistance in strong acid and alkali media and prevents pitting, crevice corrosion and SCC. Hastelloy C276 also has broad resistance to wet chloride gas, hypochlorite and chlorine dioxide media.

2.4819 (NiMo16Cr15W) is a wrought nickel-chromium-molybdenum-tungsten alloy that exhibits excellent corrosion resistance in a very wide range of machining environments. It has excellent resistance to stress corrosion cracking and oxidizing atmospheres up to 1040°C, while the high molybdenum content gives the alloy excellent resistance to pitting and crevice corrosion.

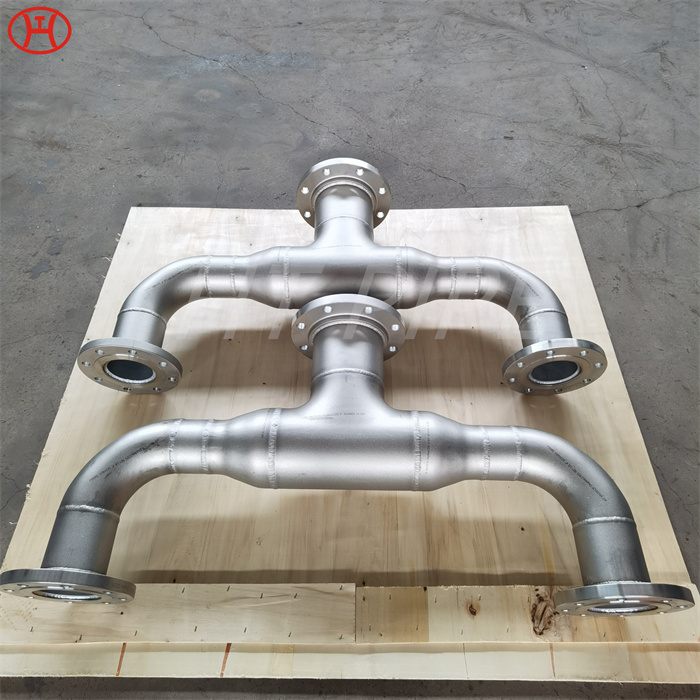

Hastelloy C-276 prevents local and intergranular corrosion in the presence of strong acids such as sulfuric, phosphoric, hydrochloric, nitric and organic acids. It has excellent corrosion resistance to various sulphuric acids up to 95oC or 200oF. For chloride concentrations around or above 0.1% and pH 2, C276 alloy is suitable for use. It is suitable for the medium with the highest temperature in the flue gas desulfurization system and its components such as fan impeller, damper, liquid spray, pipeline, etc.