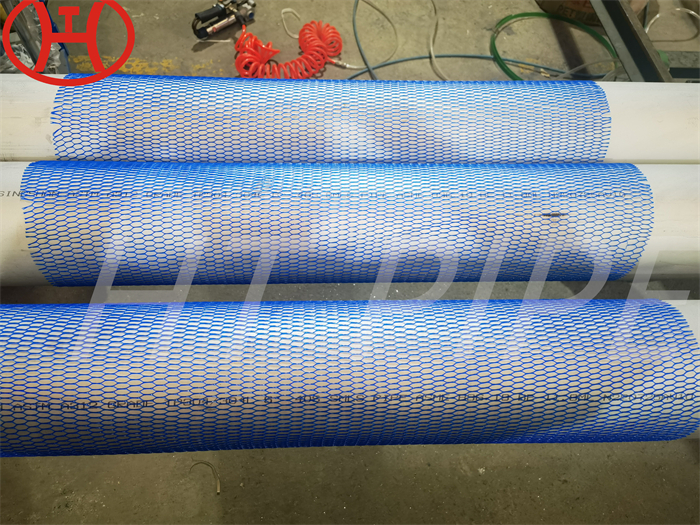

hastelloy c276 2.4819 pipe with pipe fittings flanges

Hastelloy C-276 is a nickel-molybdenum-chromium-tungsten alloy with excellent general corrosion resistance and good machinability. The alloy should be considered for use in environments requiring resistance to thermally contaminated inorganic acids, organic and inorganic chloride-contaminated media, chlorine, formic and acetic acids, acetic acid, acetic anhydride, seawater and brine solutions.

HASTELLOY C-276 is a wrought corrosion resistant alloy. A major advantage of this alloy is that it generally does not require solution heat treatment after welding. Hastelloy resists the formation of grain boundary precipitates that reduce corrosion resistance. Alloy C-276 offers better machinability than comparable corrosion resistant Alloy C. Conventional methods are available for hot working and cold forming alloy C-276, and typical welding techniques are suitable. Alloy C-276 resists the formation of grain boundary precipitates in the weld affected zone and is suitable for the weld condition of many chemical processes. Additional benefits include resistance to pitting, stress corrosion cracking and oxidation to 1900¡ã F (1038¡ã C). C276 has good machinability and impressive corrosion resistance in some of the harshest environments. Due to its properties, C 276 is commonly used in pollution control, chemical, petrochemical and waste incineration applications.