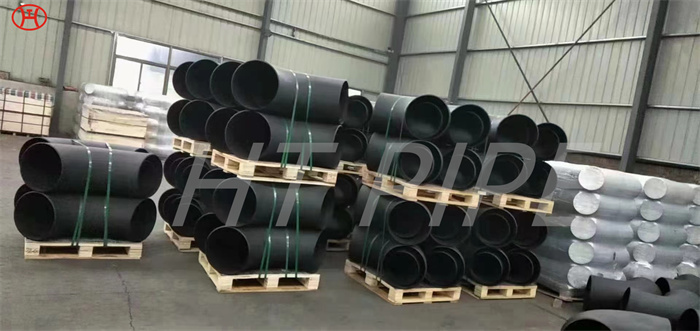

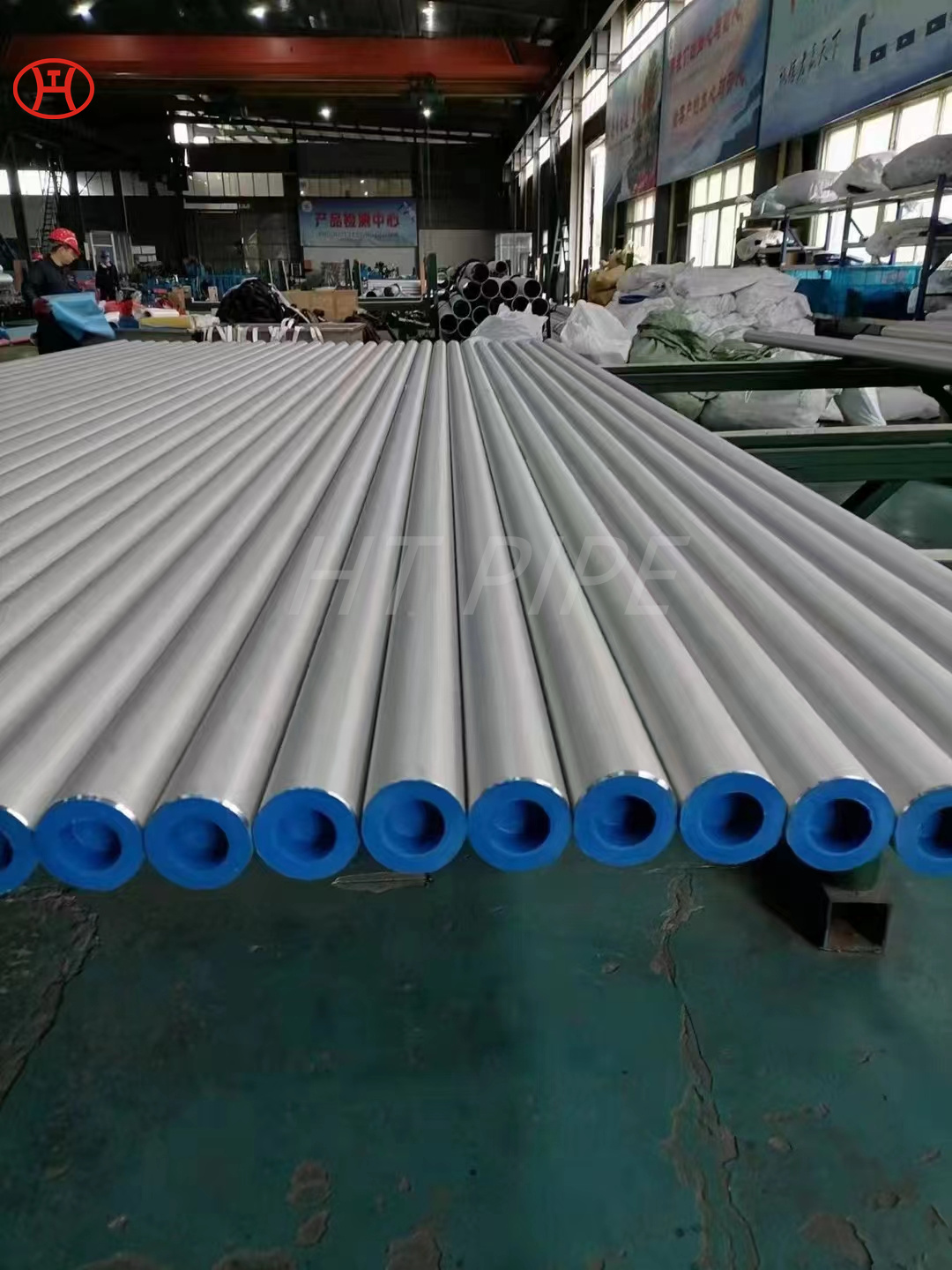

Hastelloy C276 butt welded elbows immune to chloride-induced stress corrosion cracking

Hastelloy offer very good resistance to strong reducing and moderately oxidizing corrosive acids, as well excellent stress corrosion cracking resistance and resistance to localized attack.

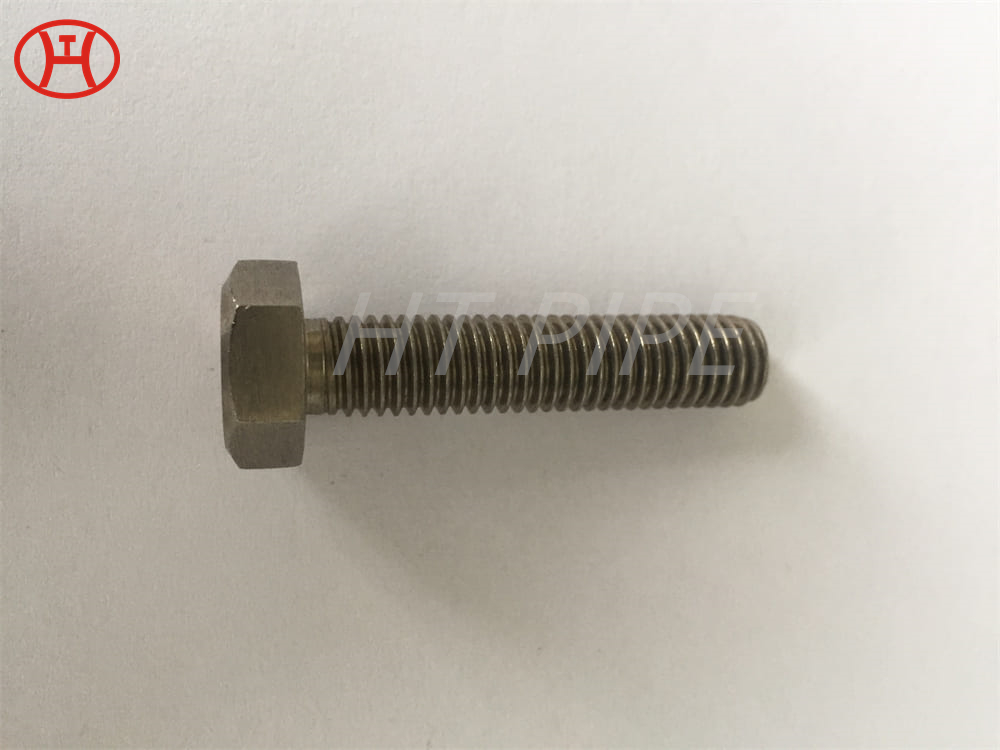

Hastelloy C276 is a nickel-molybdenum-chromium super alloy with an addition of tungsten and is designed to have excellent corrosion resistance in a wide range of severe environments. The high molybdenum content makes the alloy especially resistant to pitting and crevice corrosion. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures. The alloy is considered moderate to difficult to machine, but can be machined using conventional methods. The alloy has a high work hardening rate, and efficient machining requires rigid and overpowered machines, sharp tools, preferably carbide-tipped, and heavy, constant feeds.