hastelloy c276 fasteners N10276 bolts screws nuts and washers

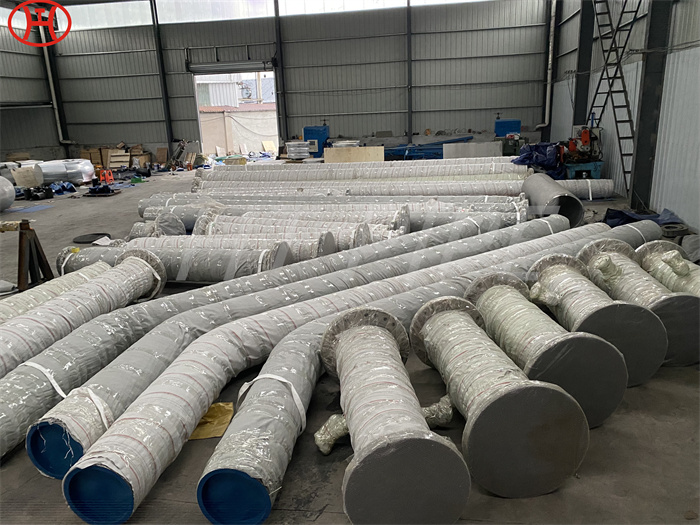

Hastelloy fasteners can be used in applications involving a wide range of media, including reducing acids and oxidizing agents. As the most versatile alloy c276 fastener, it is most commonly used for bolting of all Hastelloy grade fasteners.

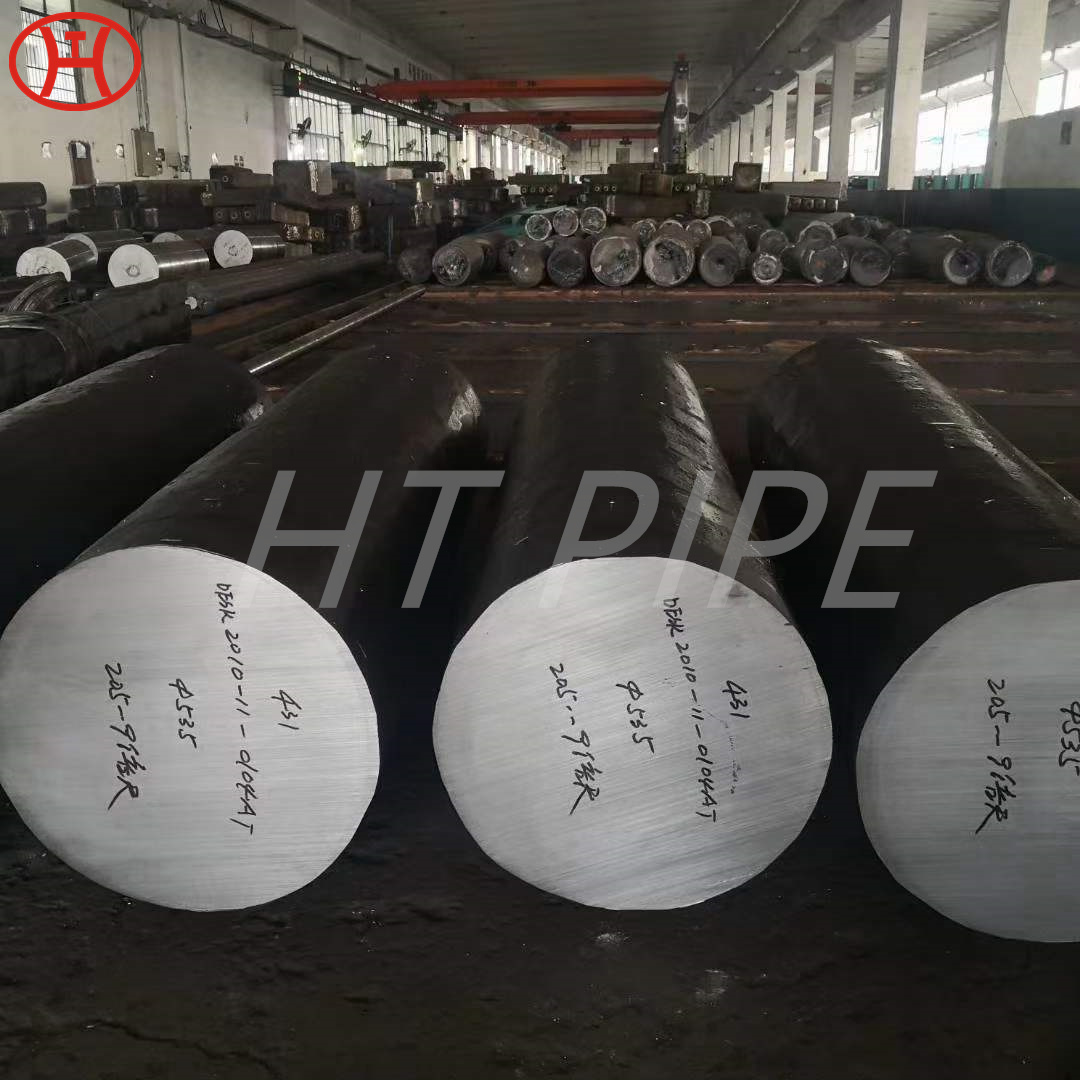

Hastelloy C276 is a nickel-molybdenum-chromium alloy with the addition of tungsten, designed for excellent corrosion resistance in a variety of harsh environments. Also known as Alloy C276 The high nickel and molybdenum content makes this alloy particularly resistant to pitting and crevice corrosion in reducing environments, while chromium is resistant to oxidizing media. The low carbon content minimizes carbide precipitation during welding to maintain the corrosion resistance of the welded structure.

In addition to this, Hastelloy C276 fasteners are used in several industries, such as the chemical, power, semiconductor and water industries. It is for this reason that Hastelloy B2 fasteners have entered some of the most corrosive environments. These Hastelloy C22 fasteners are also most commonly used in severe corrosion and heat resistant applications.

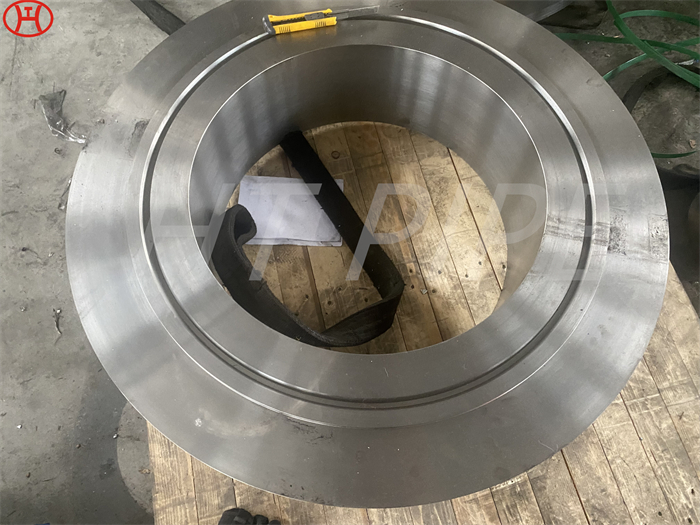

At the same time, alloy C276 bolts resist carburization or graining near the weld zone. These bolts are the first choice in systems with the highest chemical and acid exposure. This Hastelloy C276 Fastener is designed to join two or more parts together. These fasteners form a non-permanent joint that can be removed without damaging the existing structure. They can be fixed mechanically or manually.