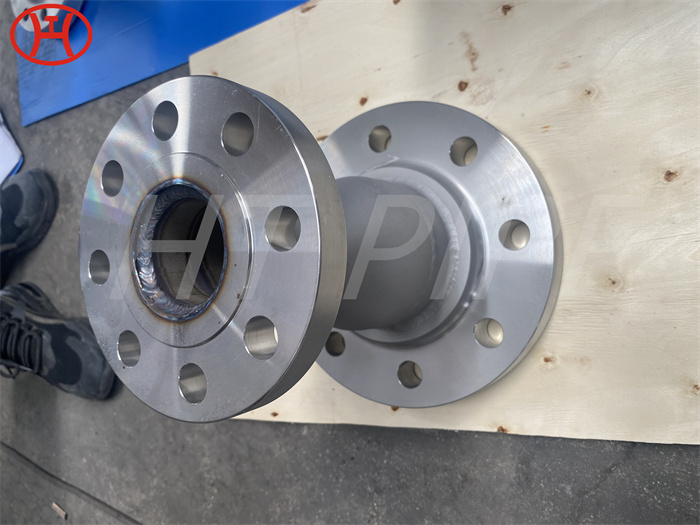

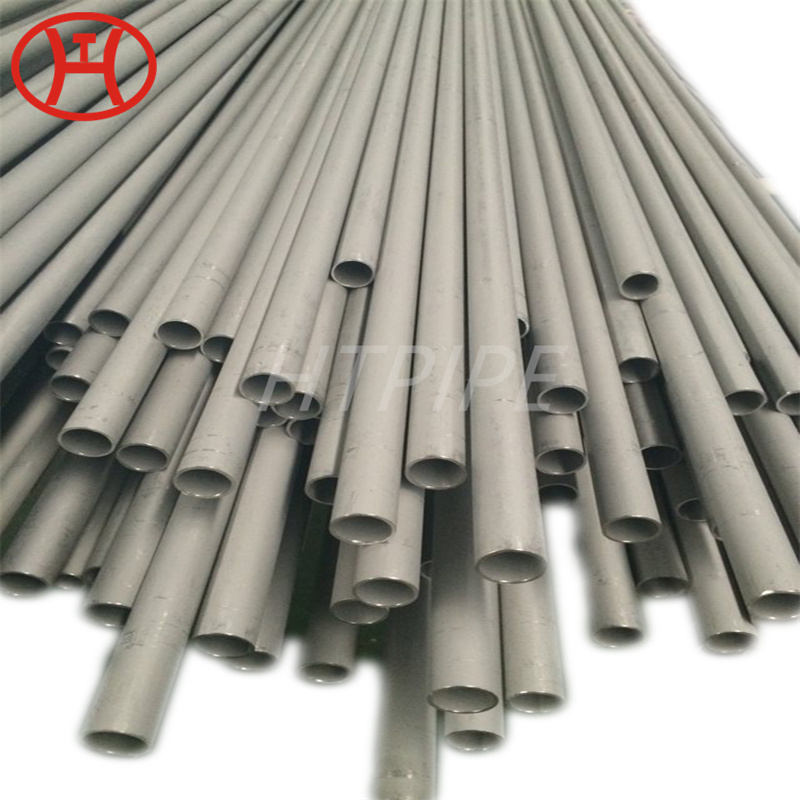

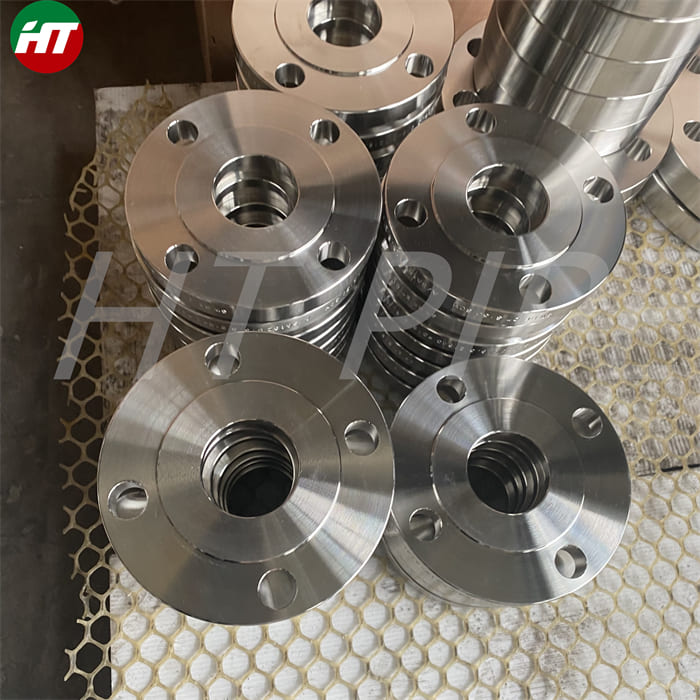

hastelloy c276 N10276 flanges butt weld with pipes

C276 is forged between 2250/1750oF (1230/955oC) and then soaked at the forging temperature for 30 minutes per inch of billet or ingot section thickness. Forging should begin immediately, the billet is removed from the reheat furnace, a 25/40% reduction helps retain as much internal heat as possible. For optimum corrosion resistance, forged parts should be subsequently annealed. See Heat Treatment.

Hastelloy C276 is considered one of the few alloys that is resistant to hypochlorite, wet chloride gas and chlorine dioxide solutions. It has excellent resistance to strong oxidizing salt solutions such as cupric chloride and ferric chloride. In addition, it is less prone to grain boundary precipitation as used in welding conditions. Therefore, this product is suitable for various chemical process applications. This alloy is usually supplied in the solution annealed condition. The treatment is performed at 2050oF (1120oC) followed by a water quench or rapid air cooling. Treatment is performed after hot working and between cold working operations to ensure optimum corrosion resistance.