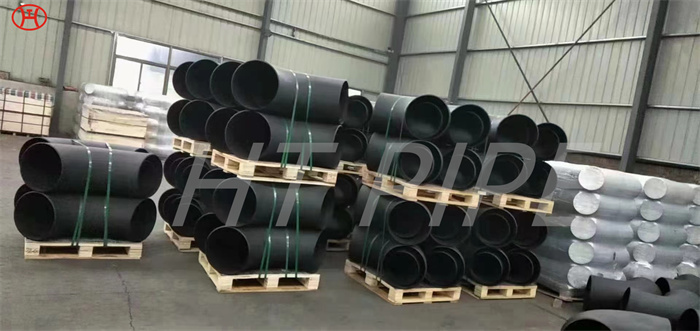

hastelloy c276 N10276 tees with elbow and flange

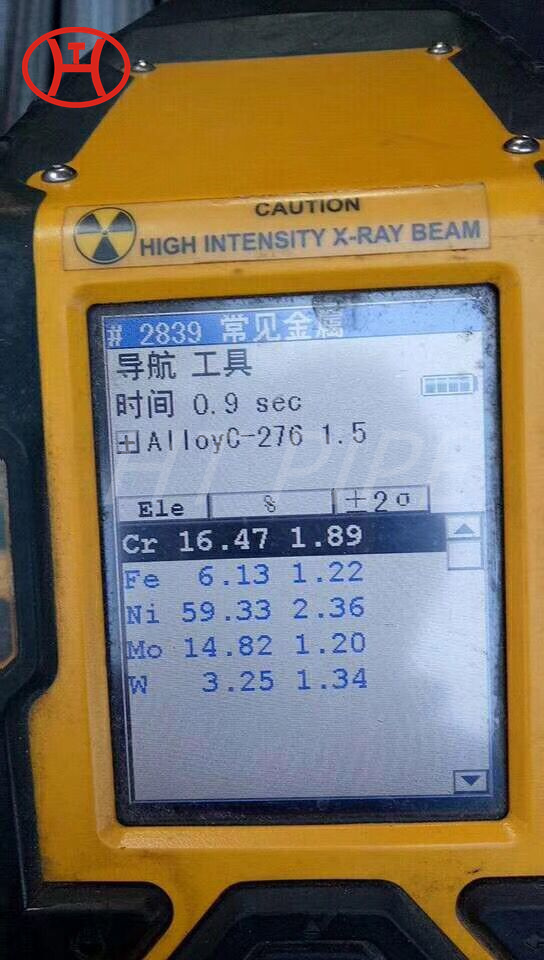

The premium composition of molybdenum and nickel content of c276 is used to make nickel steel alloys. It helps resist crevice and pitting corrosion in reducing environments. Chromium, on the other hand, is used to impart resistance to oxidizing media.

c276 has good resistance to a variety of corrosive media in redox environments and can withstand high temperatures up to 677¡ãC. The alloy has excellent resistance to various chemical process environments.

Machining Hastelloy is similar to other nickel-based superalloys with moderate hardness (eg Inconel 625). It should be machined to a positive and sharp cutting edge. Suitable geometries for austenitic stainless steels are also suitable for Hastelloy. However, it is best to use geometries and grades designed for superalloys.