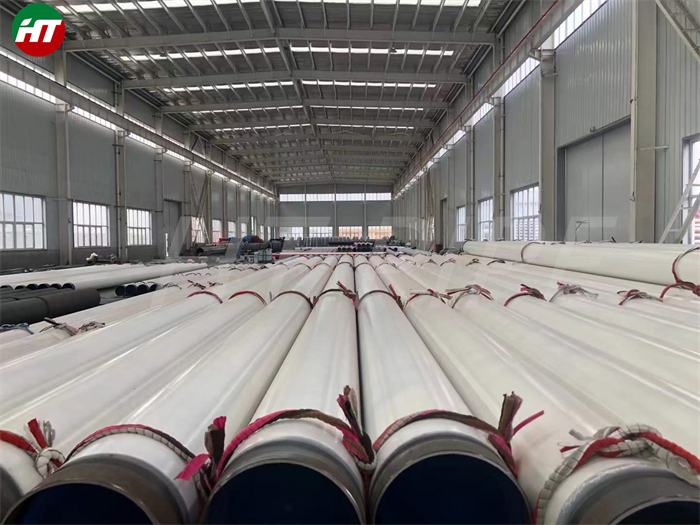

Hastelloy C4 Flange Factory Production

Hastelloy C-4 is a nickel-chromium-molybdenum alloy with outstanding high temperature stability. It has high ductility and corrosion resistance. It’s high temperature resistance up to 1900 ¡ãF (1038 ¡ãC) makes it suitable for most chemical process application in the “as” welded condition.

Like other nickel alloys, it is ductile, easy to form and weld, and possesses exceptional resistance to stress corrosion cracking in chloride-bearing solutions (a form of degradation to

which the austenitic stainless steels are prone). With its high chromium and molybdenum

contents, it is able to withstand both oxidizing and non-oxidizing acids, and is resistant to

pitting and crevice attack in the presence of chlorides and other halides.

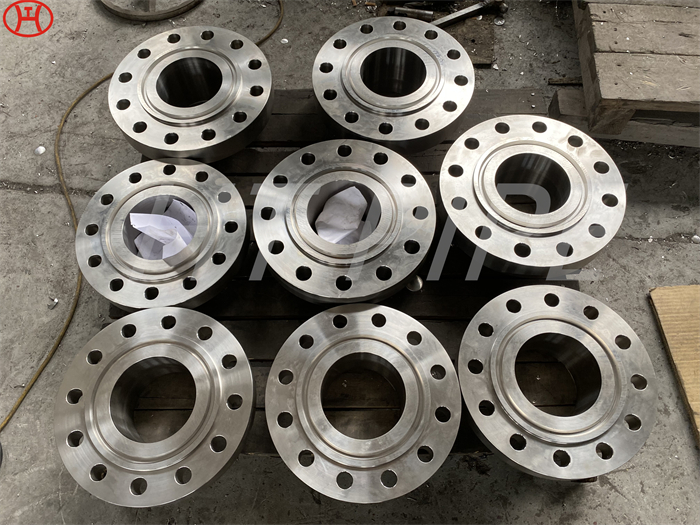

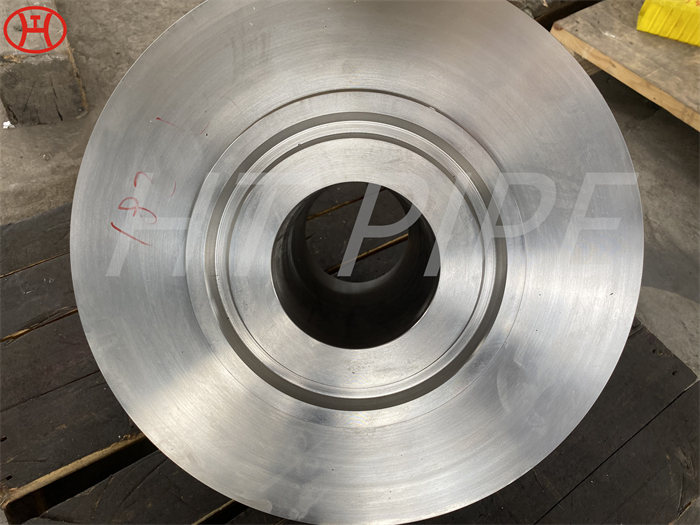

The flange is second most used joining method after welding. Flanges are used when joints need dismantling. It provides flexibility for maintenance. Flange connects the pipe with various equipment and valves .Breakup flanges are added in the pipeline system if regular maintenance inrequired during plant operation.

A flanged joint is composed of three separate and independent although interrdlated components; the flanges, the gaskets, and the bolting; which are assembled by yet another influence, the fitter. Special controls are required in the selection and application of all these elements to attain a joint, which has acceptabel leak tightness.