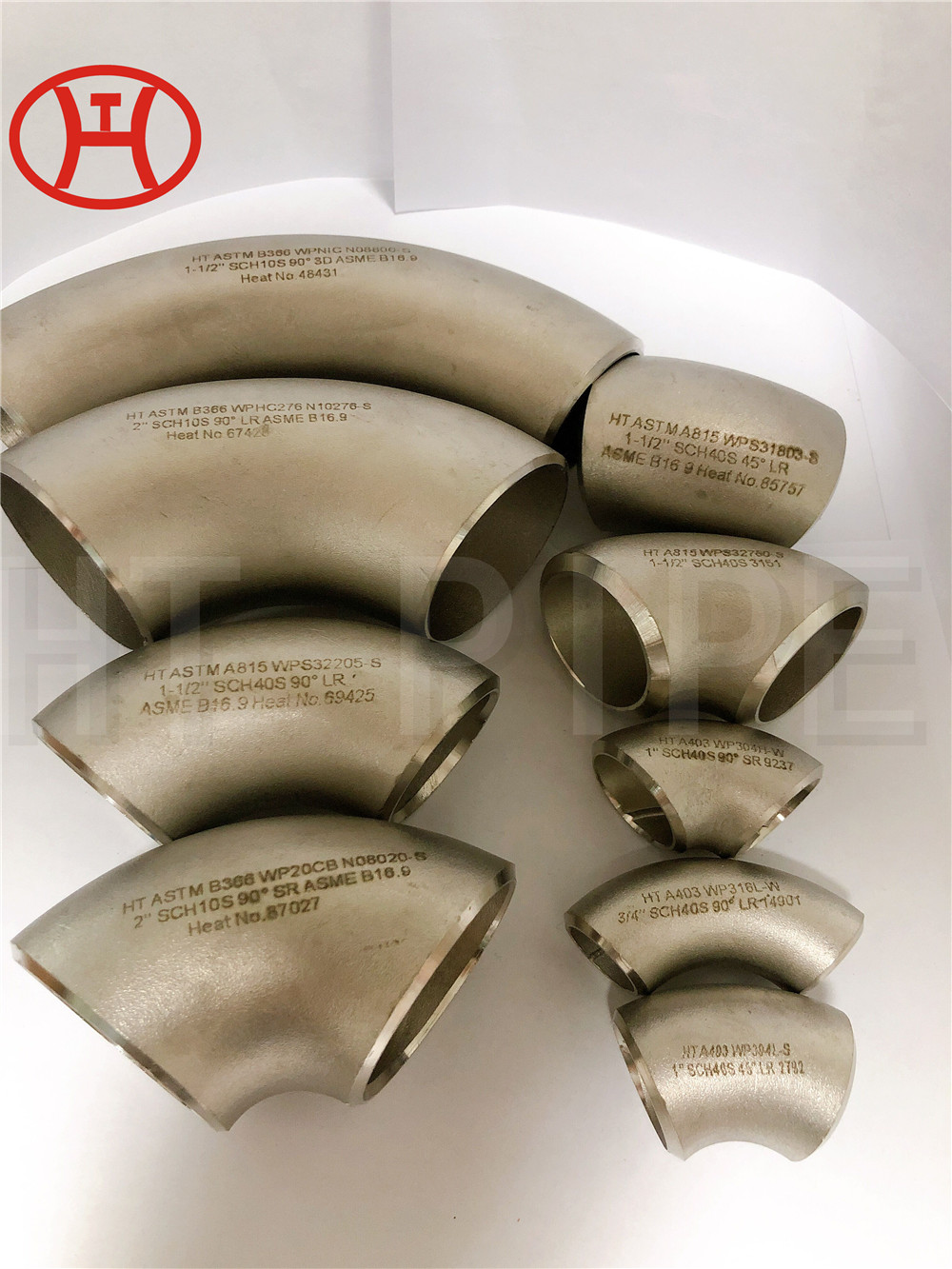

Hastelloy DIN 2.4665 Socket Weld Flanges Supplier in China

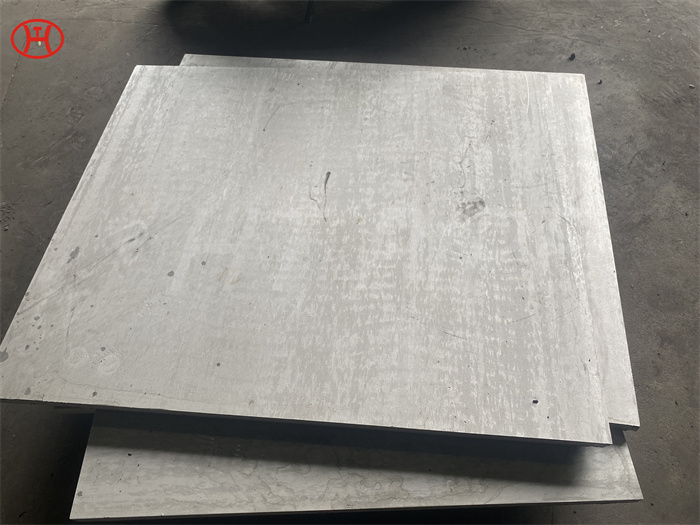

These alloys of flanges are exceptionally resistant to stress corrosion cracking petrochemical applications. Moreover, the molybdenum content results in outstanding strength in solid solution alloy that considers excellent fabrication attributes.

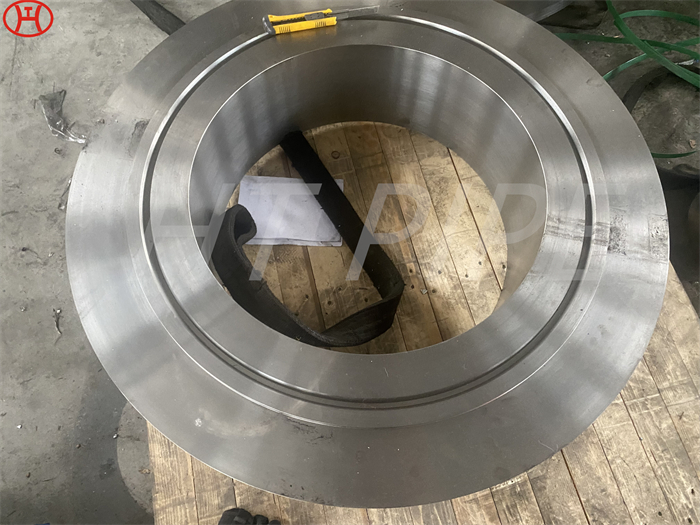

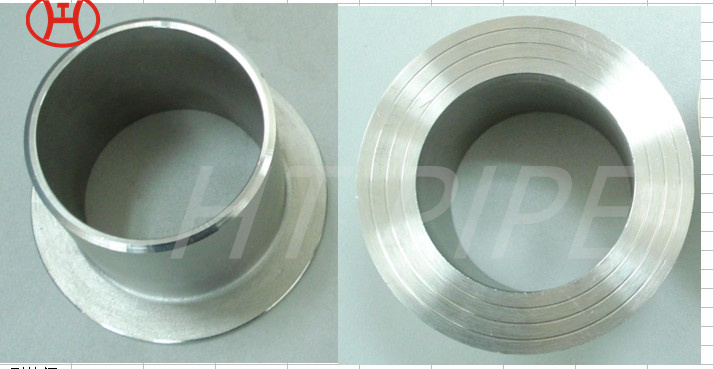

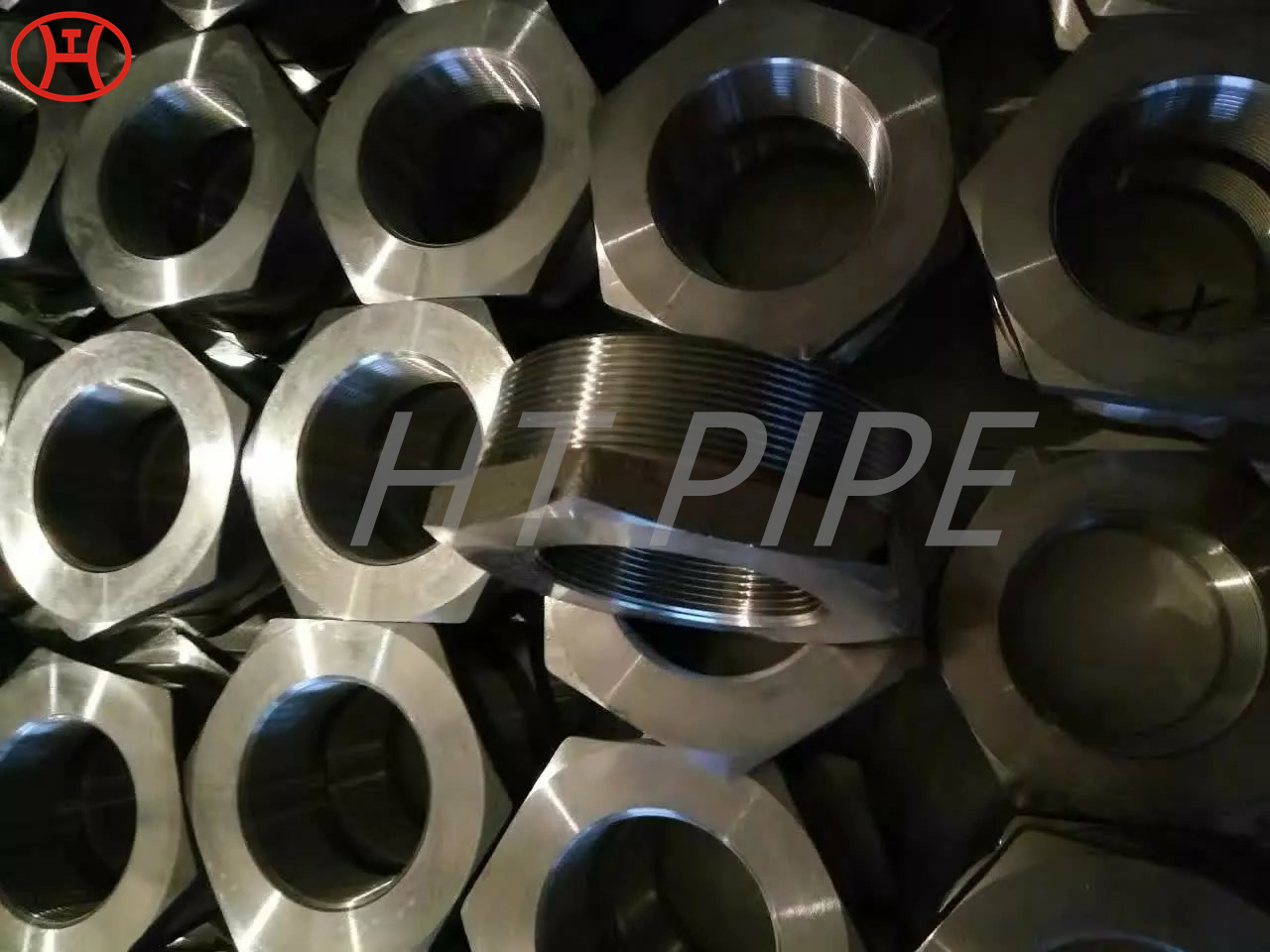

All of the product forms, including the Hastelloy X Flanges, are excellent in terms of forming and welding. Although Alloy X is primarily known for its ability to resist both heat and oxidation, these flanges also have good resistance to chloride stress related corrosion cracking. Hastelloy X Slip on Flanges has good resistance to stress-corrosion cracking and carburization make it suitable for petrochemical processing equipment and all types of forming and welding. We produce Hastelloy X Flanges in almost all shapes, sizes, dimensions, specifications and designations. We are also offering these flanges in standard and non-standard forms. Hastelloy X is a nickel-chromium-iron-molybdenum alloy with an exceptional combination of resistance to oxidation and high-temperature strength. Hastelloy X Threaded Flanges (UNS N06002) has high quality up to 1500 Degree F (816 Degree C) and great oxidation resistance up to 2200 Degree F (1204 Degree C). Nickel, chromium, molybdenum and iron make these Hastelloy X Slip On Flanges one of the world’s most popular proprietary alloys.