Hastelloy G30 round bar

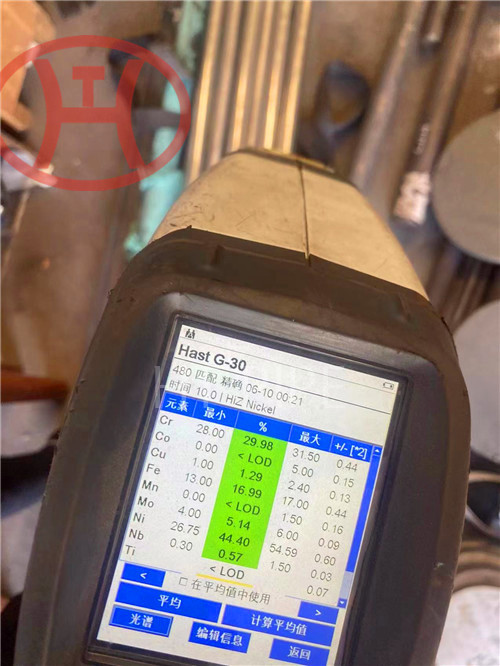

Hastelloy G30 Hastelloy alloy is a kind of nickel base high temperature alloy composed of nickel, chromium, cobalt, tungsten and other elements, the nickel content is about 37%.

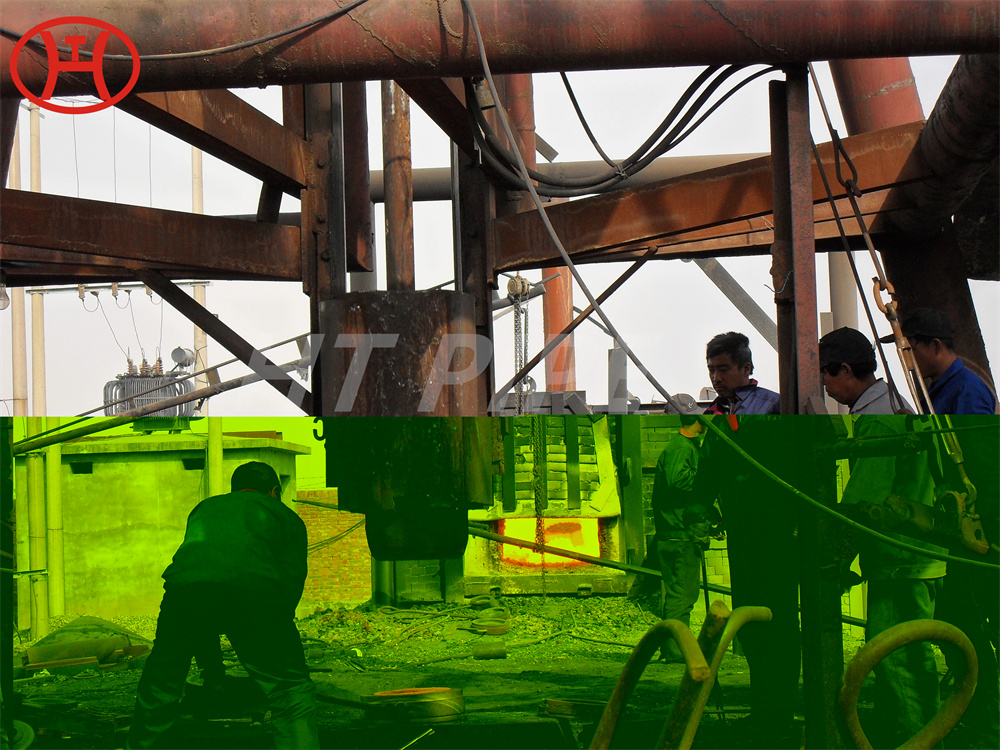

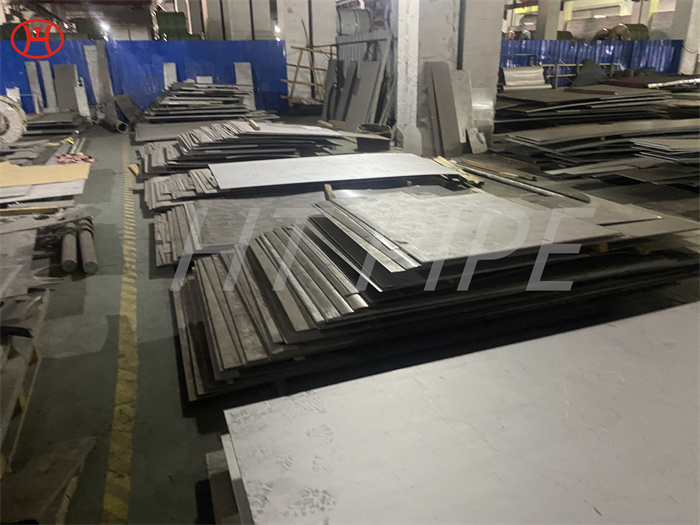

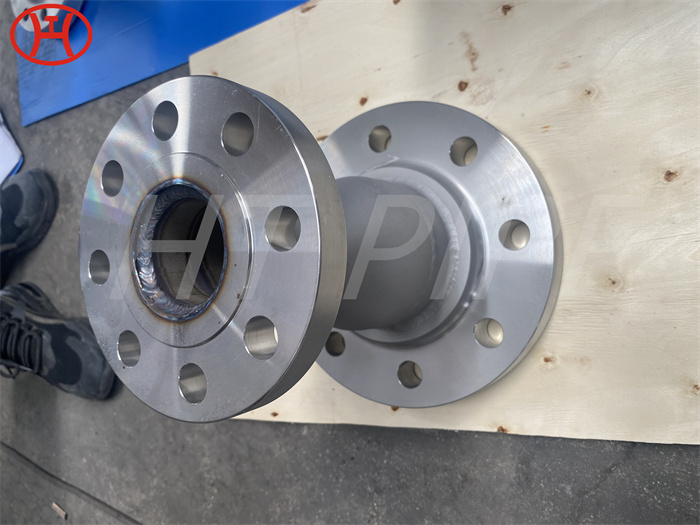

HastelloyG30 HastelloyG30 alloy has corrosion resistance, good HastelloyG30 processing properties and HastelloyG30 high strength HastelloyG30 nickel iron chromium molybdenum copper alloy sheet HastelloyG30 HastelloyG30 bars HastelloyG30 strip HastelloyG30 pipe HastelloyG30 forgings Hartz alloy is ultra-low carbon type, Ni, Mo, Cr series nickel-based, corrosion resistant, high temperature resistant materials Haselloy, because it has excellent high temperature resistance, oxidation resistance, weld impact zone corrosion resistance, has good long-term thermal stability and processability, in the agricultural chemical industry, nuclear facilities, biopharmaceutical and other harsh industrial environment is used. It in wet oxygen, acetic acid and the strong oxidizing salt medium, also have excellent corrosion resistance, uniform corrosion, intergranular corrosion resistance, therefore also widely used in chemical industry, the conductivity of the hartz alloy and coefficient of thermal conductivity than mild steel is much lower, and the resistance rate and inflation rate are much higher than low carbon steel and molten pool of liquidity is poor, poor wettability, penetration is small, melting depth. Type Round Bar

Square Bar

Hexagon Bar

Flat Bar

Black Or Bright Or Pickling white

Size OD: 5~500MM

Length :¡Ü12M or As per your requirement.”

Manufacturing technique Hot Rolling,Cold-drawing

Diameter Tolerance H7 H9 H10 H11