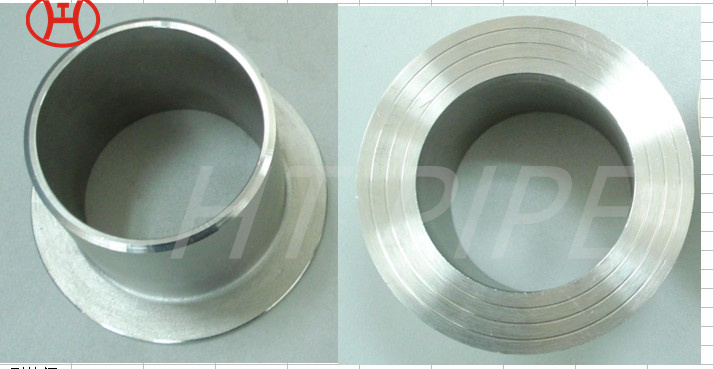

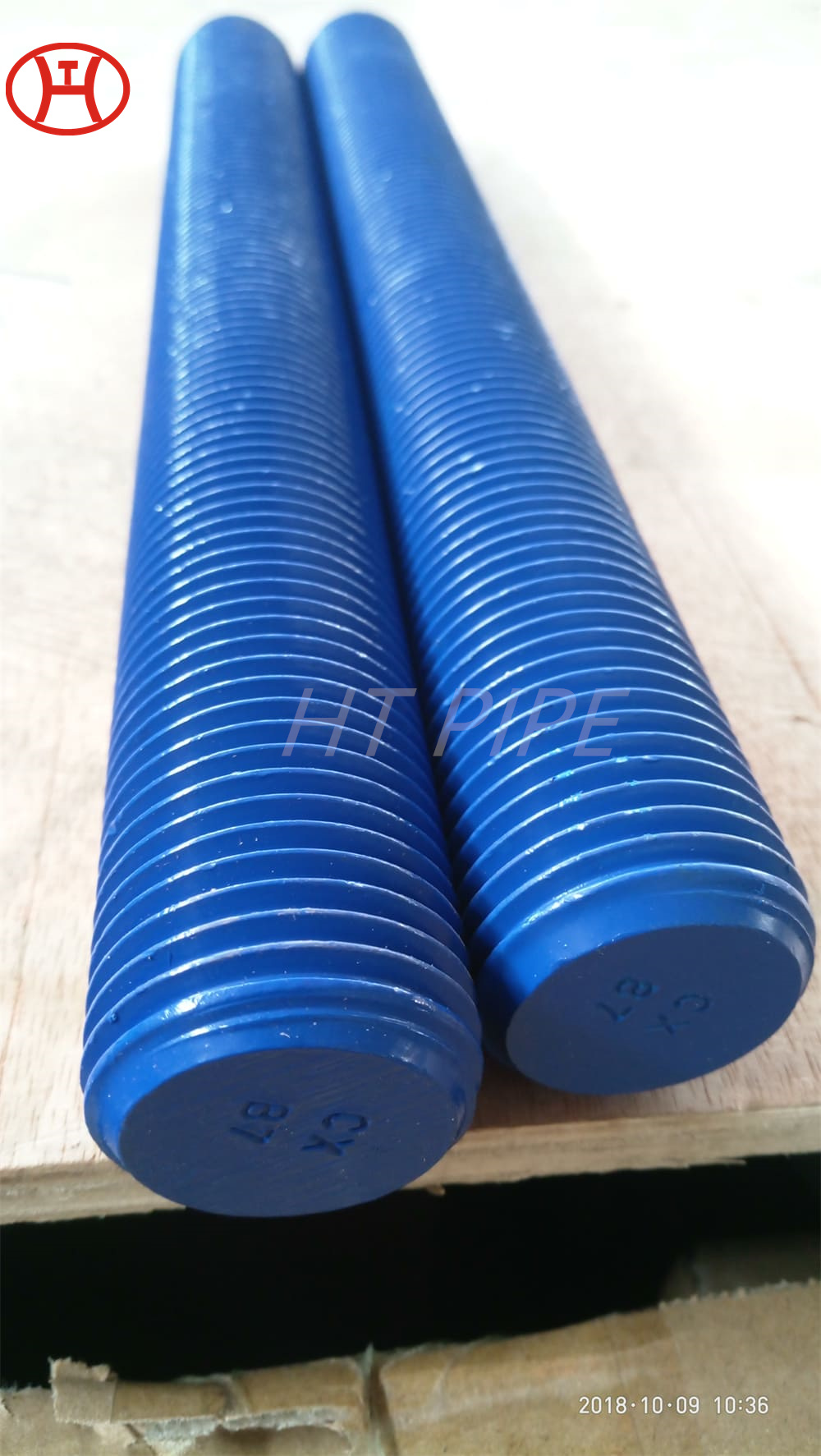

Hastelloy UNS N06002 Socket Weld Flanges Hastelloy X Nippo Flanges

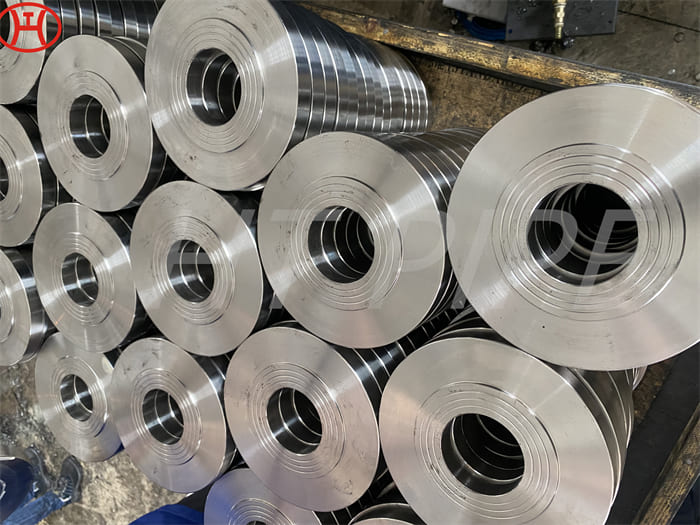

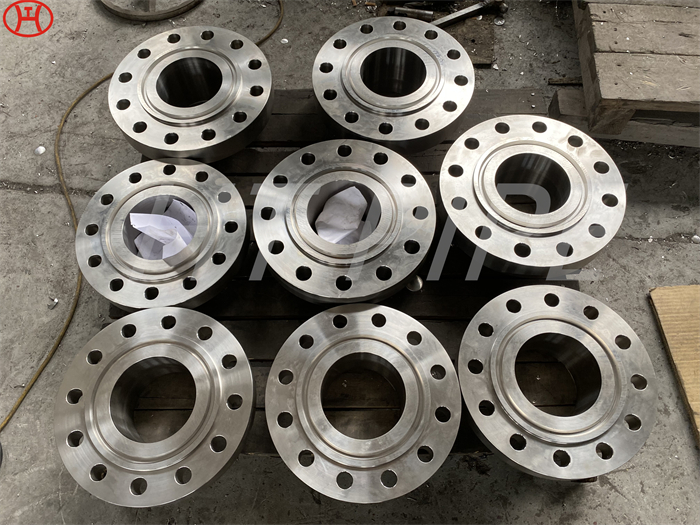

These flanges demonstrate outstanding toughness and hardness. Thus it exhibits superior ductility after prolonged exposure at a temperature of 650, 760, 870 degree C.

Hastelloy X is a nickel-chromium-iron-molybdenum super-alloywith outstanding high temperature strength, oxidation resistance, and fabricability Hastelloy X flanges, which are in stock and available now, are generally considered a versatile and highly corrosion resistant alloy. Its corrosion resistance to SCC would mean that these ASTM B564 UNS N06002 Flanges are a well valued asset in the petrochemical industry, as the alloys that are a part of this sector need to have a mix of high mechanical strength and corrosion resistance property. Our offered flanges can efficiently work under the high mechanical stress and high temperatures and also in applications that needs high surface stability. Basically Hastelloy X is a wrought nickel base alloy comprising excellent oxidation resistance and high temperature resistance. These Flanges are easily farbicable and machianble. In addition to demonstrating has good resistance to carburization, the WNR 2.4665 Threaded Flanges also has excellent resistance to reducing atmospheres. Amongst all the nickel based alloy grades, Hastelloy X flanges are one of the most widely used superalloys as a part of gas turbine engine components.