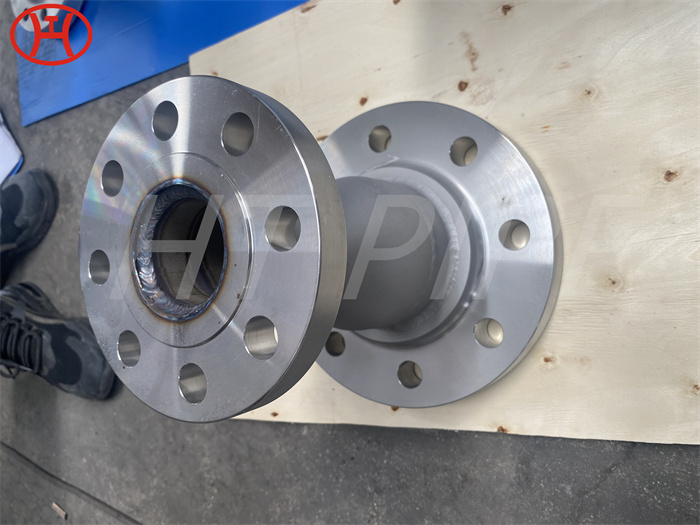

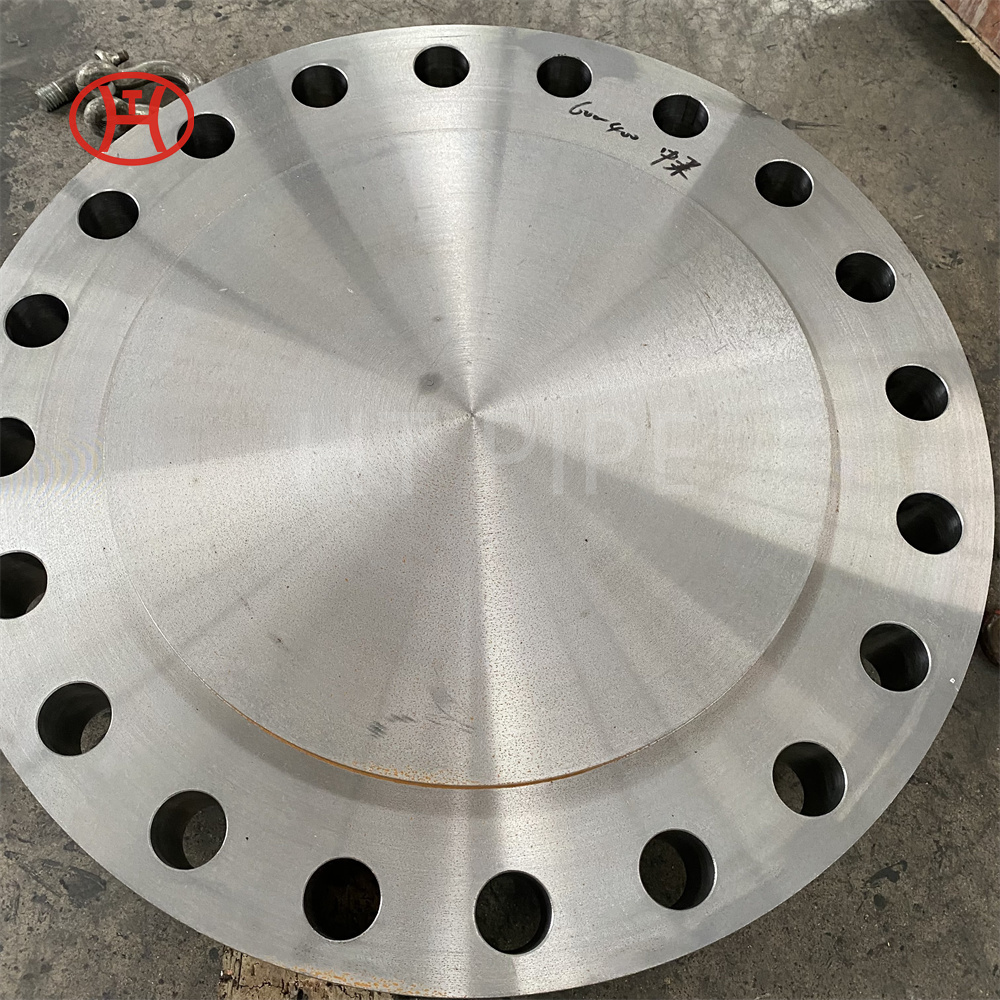

Hastelloy Weld Neck Flanges HASTELLOY B2 WELD NECK FLANGES EXPORTER

Our Hastelloy B2 Ring Joint Type Flanges is not recommended for use in the presence of ferric or cupric salts as these salts may cause rapid corrosion failure. Ferric or cupric salts of these Hastelloy B2 Nippo Flanges may perhaps develop when hydrochloric acid comes in contact with iron or copper.

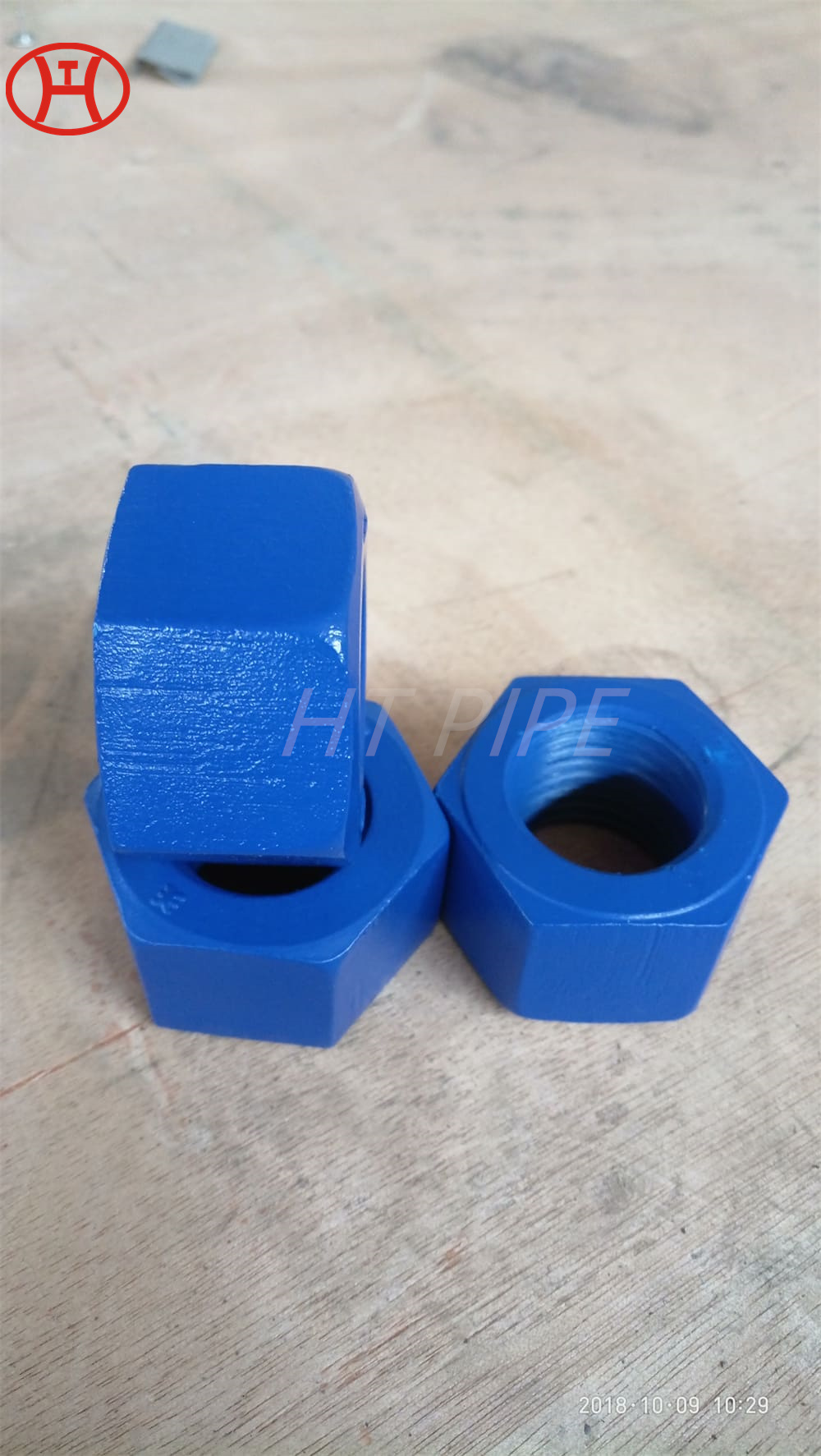

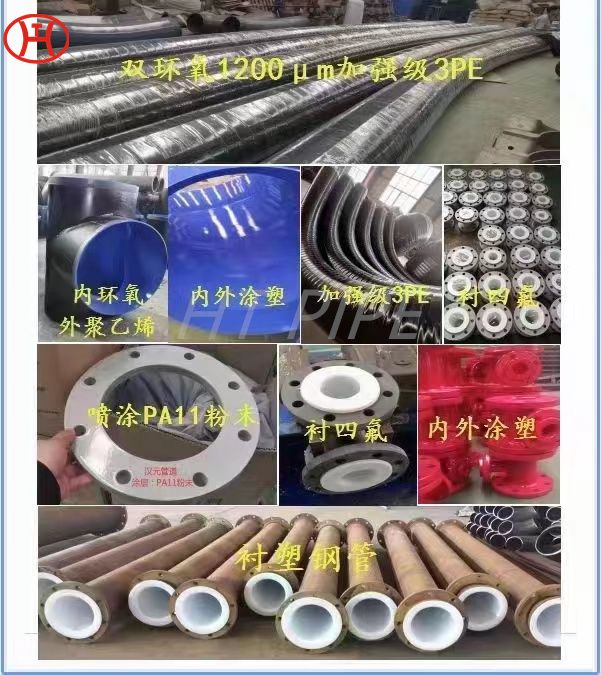

ANSI B16.5 Hastelloy C276 Slip On Flanges has a greater thermal stability. ANSI B 16.5 Hastelloy X Square Flanges are used to connect other threaded components in low pressure and non critical environments. Provide technically sound solutions and create additional value in mutual interest with our customers resulting in being a preferred manufacturer within the Fitting and Flanges sector. ASTM B564 UNS N10665 Flanges are able to perform admirably in applications that involve acids such as phosphoric, sulfuric, hydrochloric and acetic acid, in the chemical process industry. Our products are manufactured under the supervision of the professionals, who carry quality check at every stage of production. These equipment are preferred by our clients due to their unique features including reliability, durability, easy operation, reasonable price, dimensional accuracy, high-end finishing, etc. Any kind of nickel based component such as B2 Hastelloy Slip On Flange produced under the ASTM B564 specification are required to conform to the grain size in addition to the mechanical properties, testing procedures as well as chemical composition.