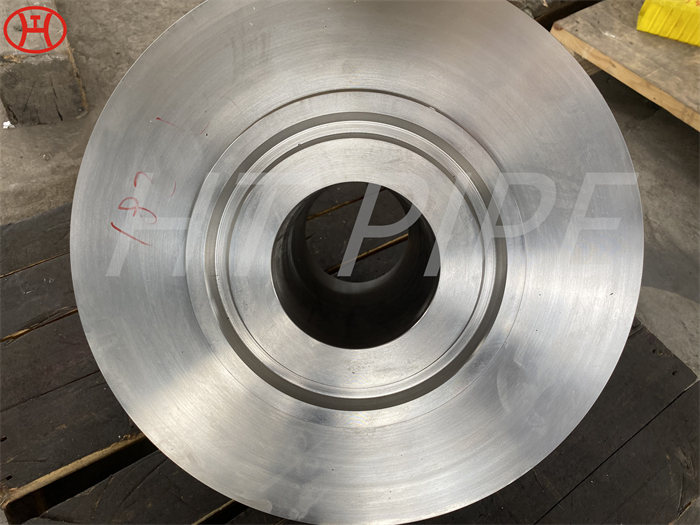

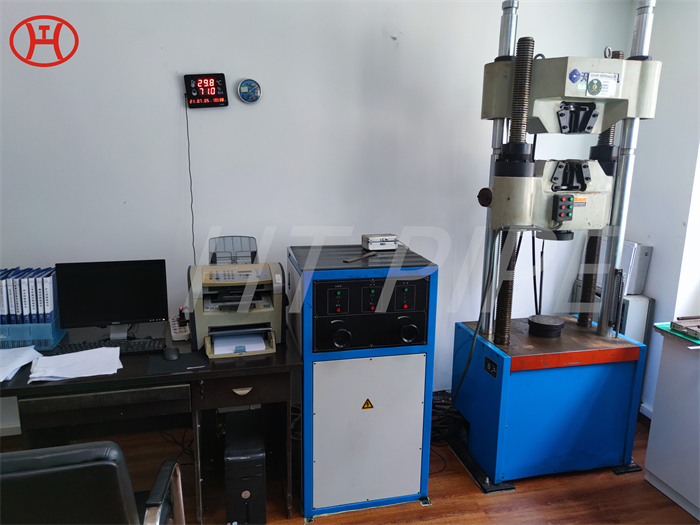

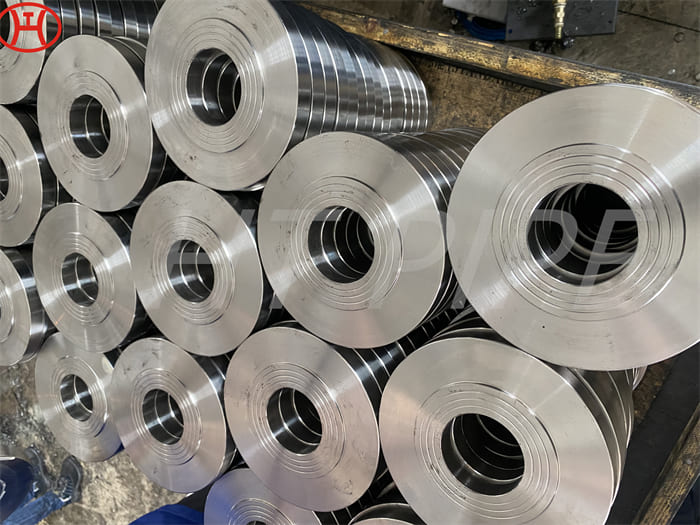

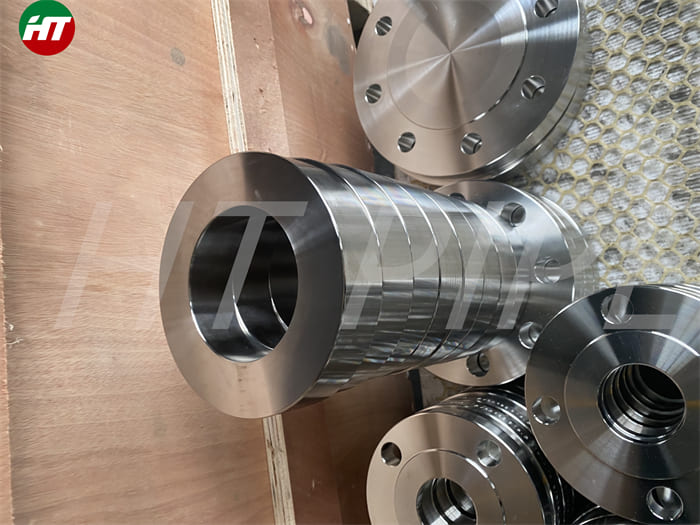

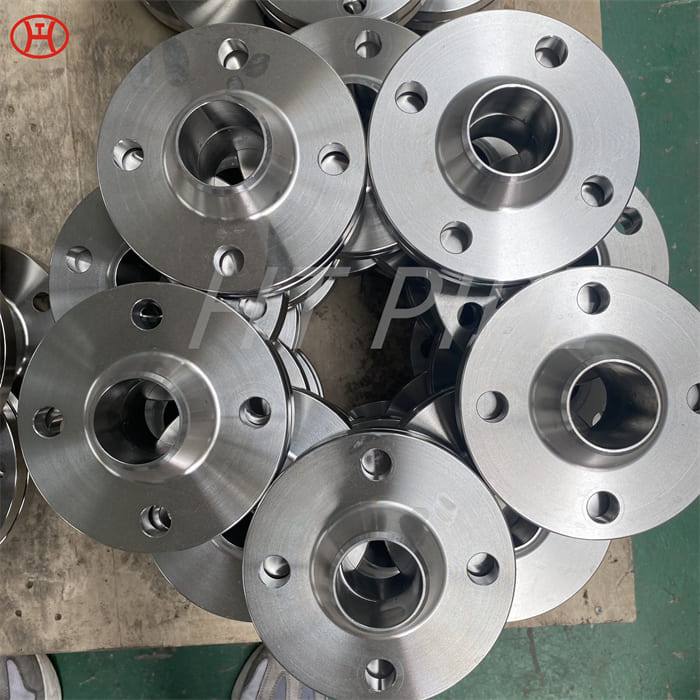

Hastelloy X Flange Quality Inspection Scenario

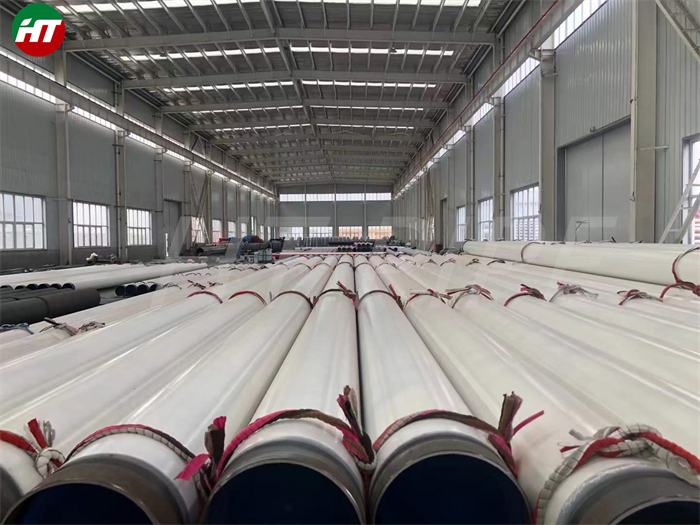

Incoloy alloy is applied as the prefix name to several highly corrosion resistant high temperature strength metal alloys produced by Special Metals Corporation. Nickel alloys are excellent for heat exchangers in the chemical processing and nuclear industries. They’re used in steam generator tubing in the nuclear power industry, in high-temperature aircraft systems, and in oil and gas extraction programs where corrosion-, pressure- and temperature-resistant tubing is required

The flange is second most used joining method after welding. Flanges are used when joints need dismantling. It provides flexibility for maintenance. Flange connects the pipe with various equipment and valves .Breakup flanges are added in the pipeline system if regular maintenance inrequired during plant operation.

A flanged joint is composed of three separate and independent although interrdlated components; the flanges, the gaskets, and the bolting; which are assembled by yet another influence, the fitter. Special controls are required in the selection and application of all these elements to attain a joint, which has acceptabel leak tightness.