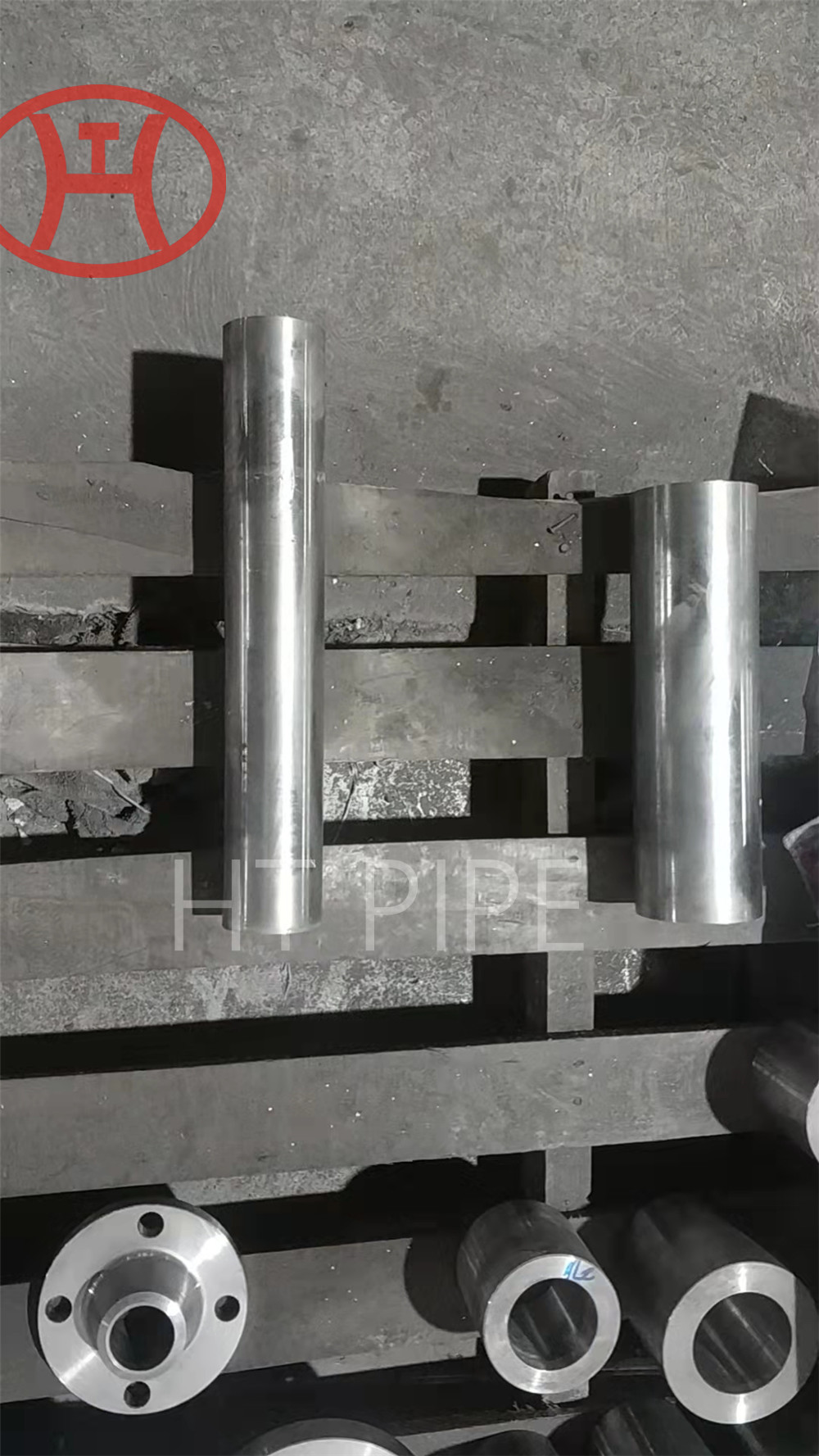

Hastelloy X Nippolet Flanges Hastelloy X Slip On Flanges

It demonstrates good resistance to neutral and reducing environments. This alloy creates a tenacious oxide, protective film that does not spall off, but it retains superior oxidation resistance at soaring temperatures.

Hastelloy alloy X Blind Flanges is machinable in the rolled and cast form at low cutting speeds and coolant is required. All rolled forms of Hastelloy X are provided in the solution heat-treated condition. Standard practice heat-treatment is 2150¡ãF followed by rapid cooling. Hastelloy X Flanges are widely used industrial furnace applications such as structural components. These Flanges are also found to be used in gas turbines in the hot combustor zone sections and petrochemical process equipment. Hastelloy X Flanges have good creep resistance and can also strengthened by, different hardening and work hardening methods. Hastelloy X is a high temperature and corrosion resistant nickel-based solid solution strengthened alloy. Hastelloy X is a high temperature and corrosion resistant nickel-based solid solution strengthened alloy. Hastelloy X Weld Neck Flanges has also been found to be exceptionally resistant to stress-corrosion cracking in petrochemical applications. Hastelloy X Lap Joint Flanges one of the most widely used nickel base super ¨C combinations for gas engine components. In the interim, these Hastelloy X Nippo Flanges are additionally being offered in customized sizes and shapes to our clients.