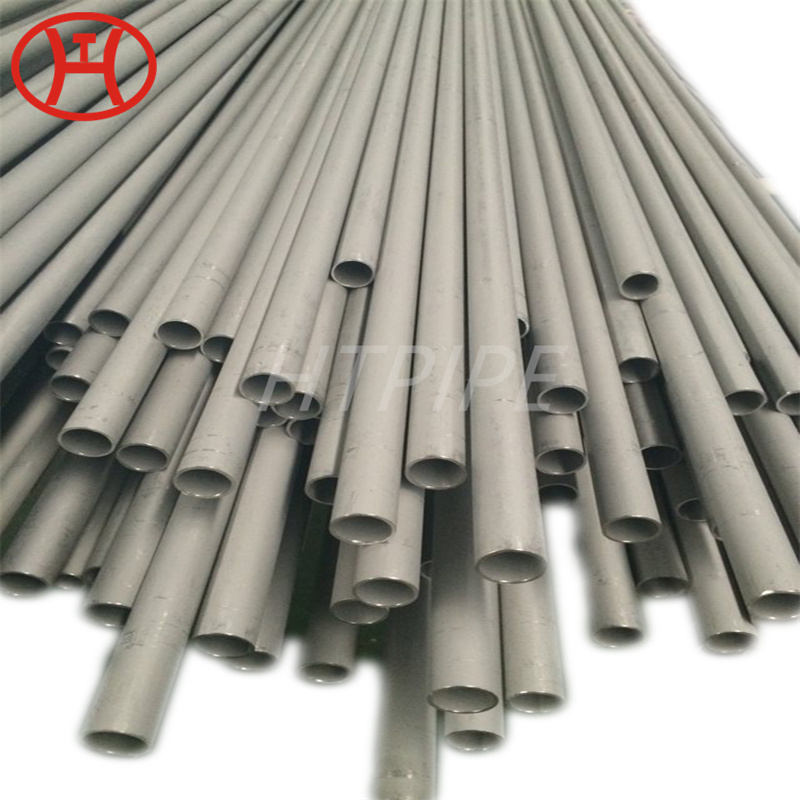

Hastelloy X pipe bend UNS N06002 pipe fittings resistance to oxidizing reducing and neutral atmospheres

Alloy X pipe bend specimens showed no carburization at all. Of ten materials evaluated in an atmosphere of hydrogen, nitrogen and ammonia at 1100 Deg. F. and 25,00 psi for 64 days, Alloy X had a nitride case less than one-fourth as thick as the closest competitive material without intergranular attack.

Hastelloy X pipe bend, a Nickel-Chromium- Iron-Molybdenum alloy is an essential structural alloy for components of gas cooled reactor equipments. The alloy is solution heat treated for strength and it can perform under cryogenic temperatures as well as high temperatures too. Hastelloy X density is 8.22 grams per centimeter cube. It has been widely utilized for above two decades in the several high temperature applications that need high strength. The applications of the material include gas turbine operations, industrial furnaces, structural components, petrochemical industries and other applications that require high temperature and corrosion resistant material.