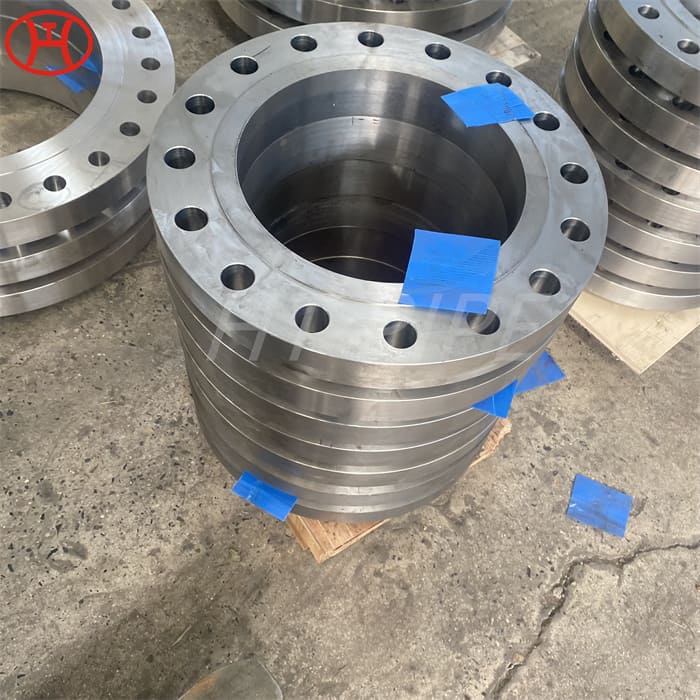

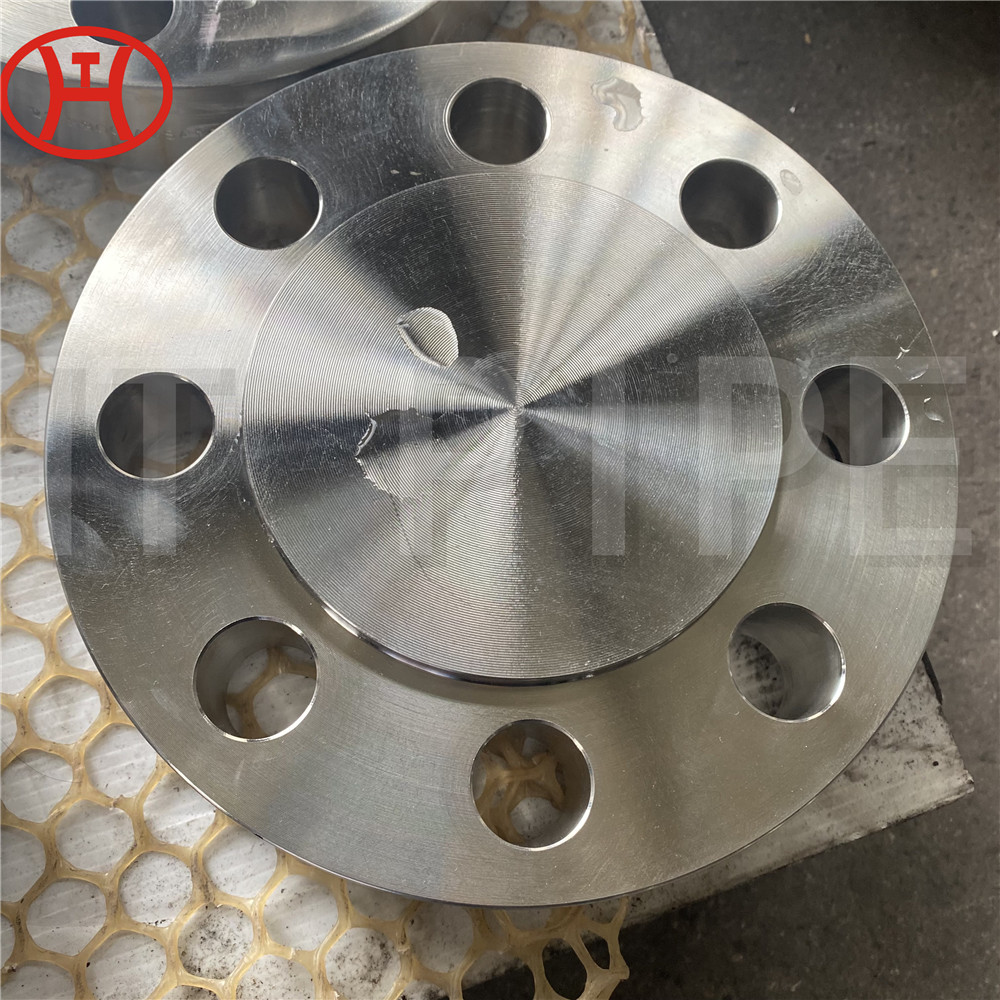

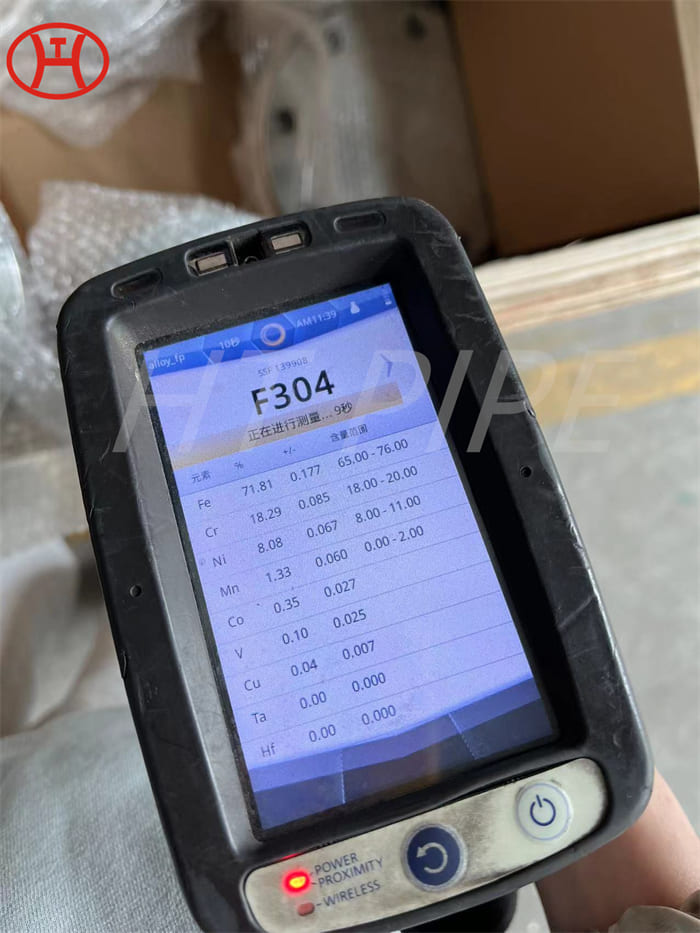

heat treatment stainless steel 304 304L S30400 S30403 flange

The purpose of preparatory heat treatment is to improve processability, eliminate internal stress and prepare a good metallographic structure for final heat treatment. The heat treatment process includes annealing, normalizing, aging, quenching and tempering, etc.

Annealing and normalizing are used for hot worked blanks. Carbon steel and alloy steel with carbon content greater than 0.5% are often annealed in order to reduce their hardness and easy to cut; carbon steel and alloy steel with carbon content less than 0.5%, in order to avoid sticking to the knife when their hardness is too low, And the use of normalizing treatment. Annealing and normalizing can still refine grains and uniform structure to prepare for subsequent heat treatment. Annealing and normalizing are usually scheduled after blank fabrication and before rough machining.