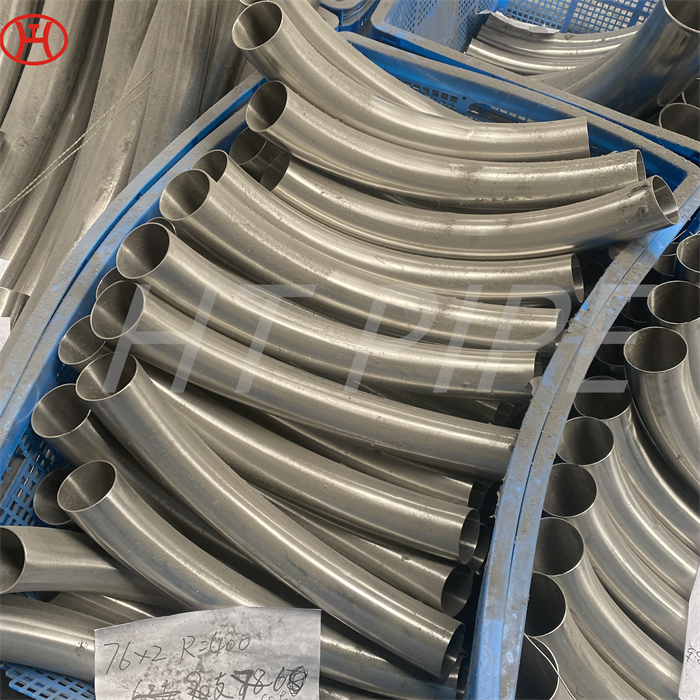

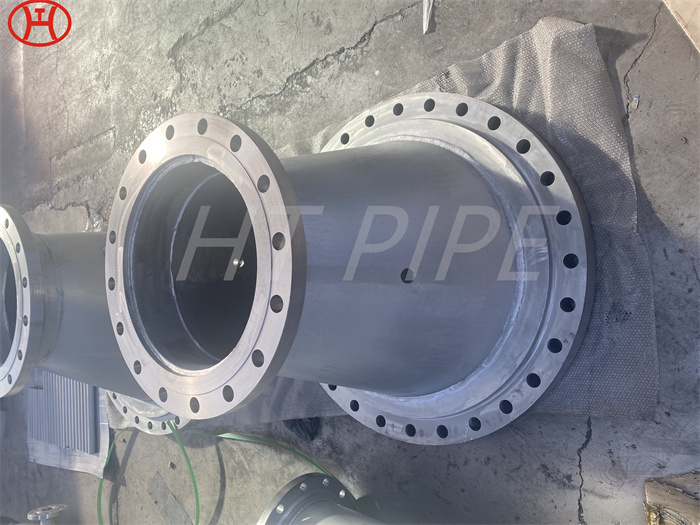

High-strength DIN 2.4602 Pipe bend employed to connect piping equipment of dissimilar sizes

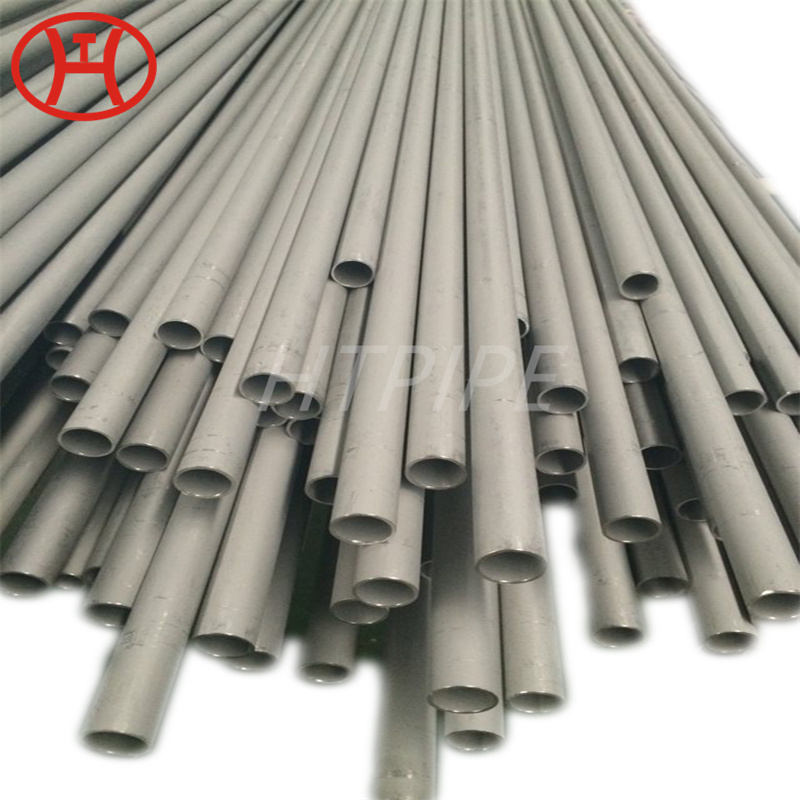

C22 is typically provided in the annealed condition with a minimum yield strength of 45 ksi. However, C22 can be cold worked to higher strength levels.

Alloy 22 (UNS N06022) is the most versatile Nickel-Chromium-Molybdenum-Tungsten alloy with controlled Iron. Due to Alloy 22’s content this alloy exhibits excellent resistance to both oxidising and reducing acid environments as well as those containing mixed acids. Alloy 22 pipe bend is particularly useful for resistance to pitting and crevice corrosion in acid-halide environments. Alloy 22 is used in pickling chlorination, sulphonation plants, pollution control, chemical processing, marine and nuclear fuel reprocessing. HASTELLOY C22 (N06022) is one of the most versatile alloys available today with resistance to both uniform and localized corrosion and a variety of mixed industrial chemicals. It is used in severely corrosive environments with high chloride and high temperature conditions, such as flue-gas scrubbers, nuclear fuel re-processing, sour gas handling, and pesticide production. It provides superior protection from pitting, crevice attack, and stress corrosion cracking.