incoloy 800h nickel tube 1.4958

800H can not be corroded in many kinds of media. Its higher nickel content made it have good stress corrosion resistance cracking properties in the water corrosion condition. High chromium content made it better resistance to pitting and crevice corrosion cracking. This alloy can resist nitric acid and organic acid, but it is not so fine in the sulfuric acid and hydrochloric acid.

800H have good corrosion resistance to both oxidation and non-oxidizing salt, but maybe a little pitting in halide, and also excellent properties in the mixture of water, smoke, steam, air and carbon dioxide.

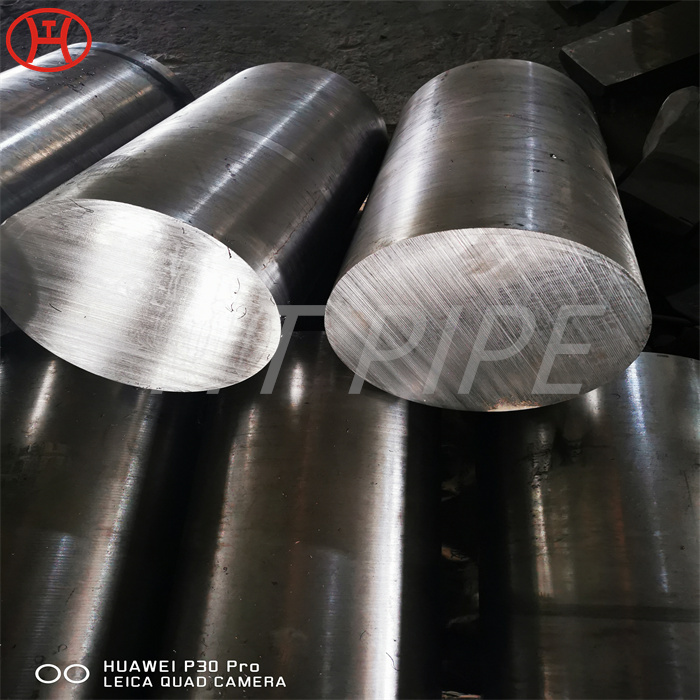

Alloys 800H and 800HT are iron-nickel-chromium solid solution strengthened alloys with a nominal chemical composition of 42% iron, 34% nickel and 22% chromium. These two grades are variants of the base grade 800 and are represented by the trade names Incoloy 800H and Incoloy 800HT and the generic names UNS N08810 and N08811, respectively. Alloy 800 (UNS N08800), Alloy 800H (UNS N08810) and Alloy 800HT (UNS N08811) have the same nickel, chromium and iron content, except for the total titanium and aluminium content (0.85 to 1.2%) to ensure optimum high temperature performance. Incoloy 800H/HT alloy is designed for high temperature structural applications. The nickel content can make the alloy highly resistant to chloride stress corrosion cracking and embrittlement by sigma phase precipitation. Ordinary corrosion resistance is very useful. Alloys 800H and 800HT have excellent creep and stress rupture properties in the solution annealed condition.