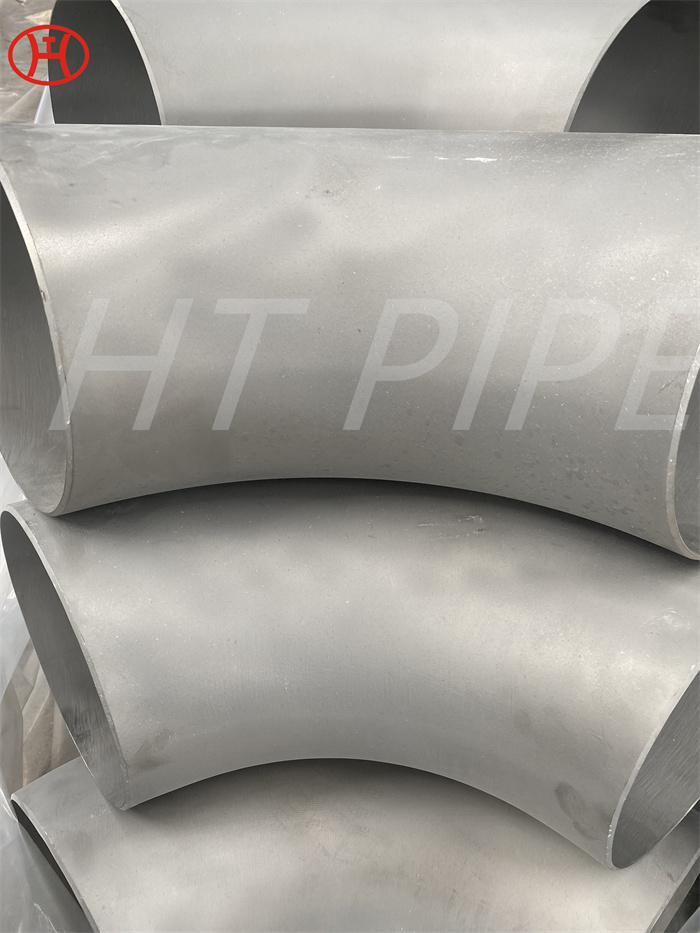

Home » Steel Pipe Fittings » Butt Weld Pipe Fittings » Incoloy 800H pipe fittings elbows also used for applications such as wet scrubbing and the reactive atmospheres of furnaces

Incoloy 800H pipe fittings elbows also used for applications such as wet scrubbing and the reactive atmospheres of furnaces

Incoloy Alloy 800HT applications have extended from petrochemical processing reformer tubing, to bellows and flare tips in refinery service. In power generation, superheater and reheater tubing has also employed the material.

Contact US

Get Price

Share:

Content

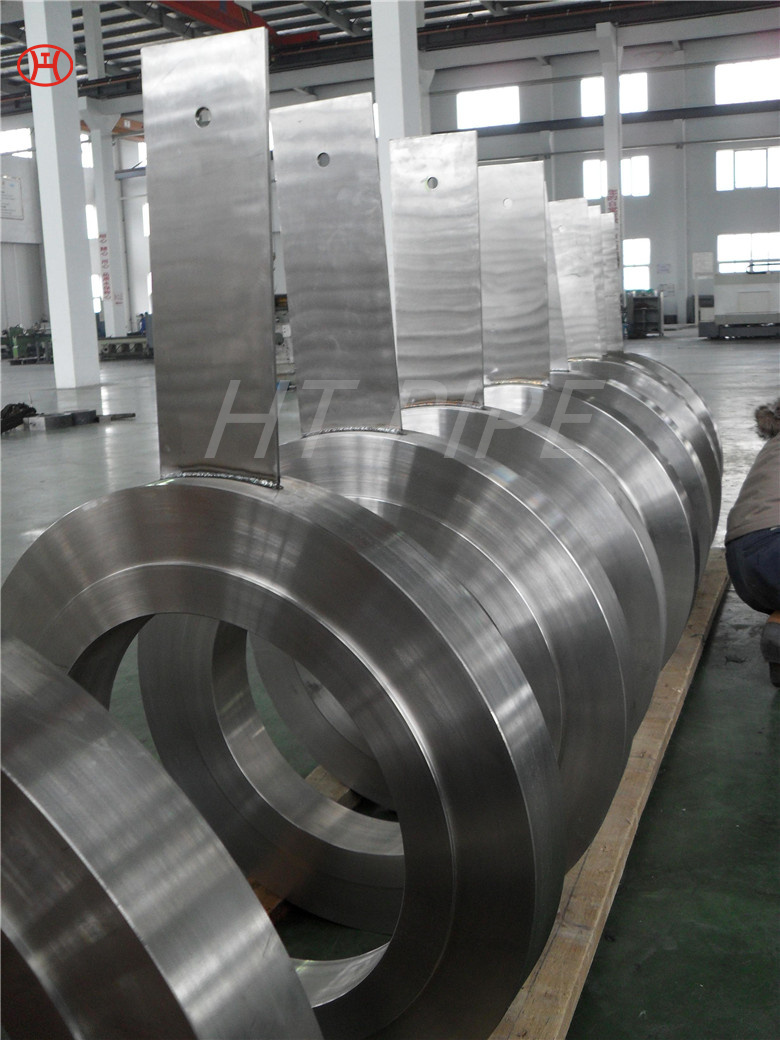

Alloy 800H/800HT are two individual solid solution strengthened, iron-nickel-chromium alloys. They are typically o?ered as one, dual certi?ed alloy, meeting the chemical composition requirements of both alloys. It is particularly useful for high-temperature equipment in the petrochemical industry because the alloy doesn’t form the embrittling sigma phase after long time exposure at 1200¡ãF (649¡ãC). Excellent resistance to chloride stress-corrosion cracking is another important feature of alloy 800.

Inquiry

More Incoloy