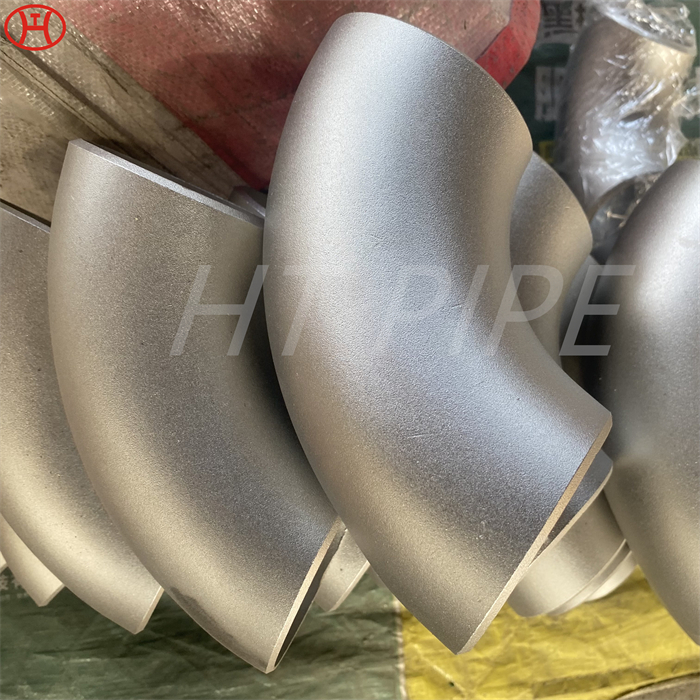

Incoloy 800H pipe fittings elbows can withstand sour gas and high chloride environments

INCOLOY 800H is widely used in Power generation, superheater and reheater tubing have also employed the material. Heat treatment retorts, muffles jigs and fixtures have also used this material to great effect.

Incoloy 800 was the first of these alloys and it was slightly modified into Incoloy 800H. This modification was to control carbon (.05-.10%) and grain size to optimize stress rupture properties. The chemical balance allows the alloy to exhibit excellent resistance to carburization, oxidation and nitriding atmospheres. 800HT will not become embrittled even after long periods of usage in the 1200-1600 deg F range where many stainless steels become brittle. Incoloy 800H is a nickel-iron-chromium alloy that is part of the family of 800 series of alloy. Also known as Nickel Alloy 800H, Incoloy 800H has many of the characteristics of the other 800 alloys.